Method of activating a mountable hydraulic appliance and such mountable hydraulic appliance

A technology of hydraulic equipment and equipment, used in shearing machine equipment, metal processing equipment, shearing devices, etc., can solve the problems of low opening and closing speed, insufficient cutting force, and large return volume of splicing jaws

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

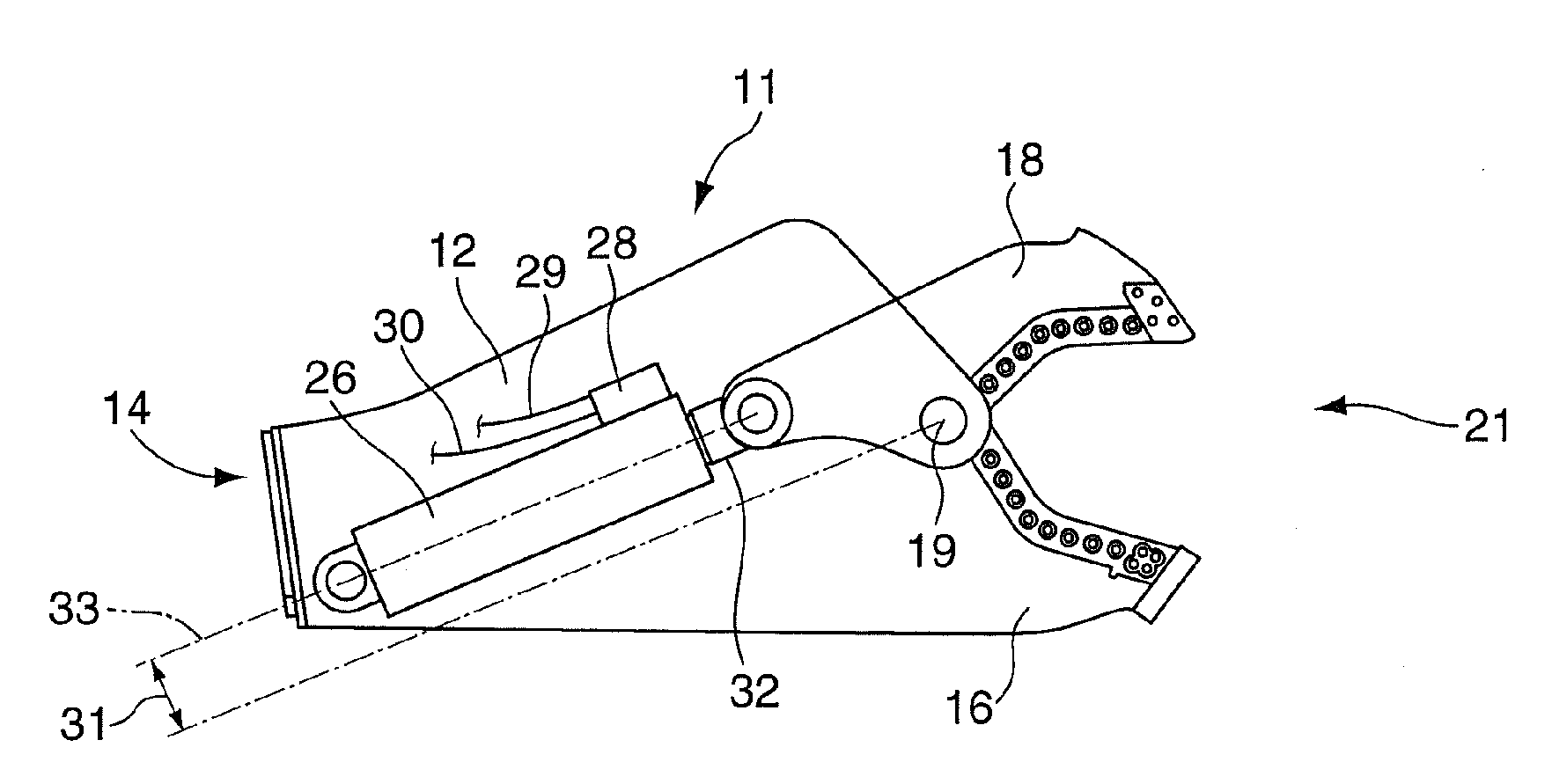

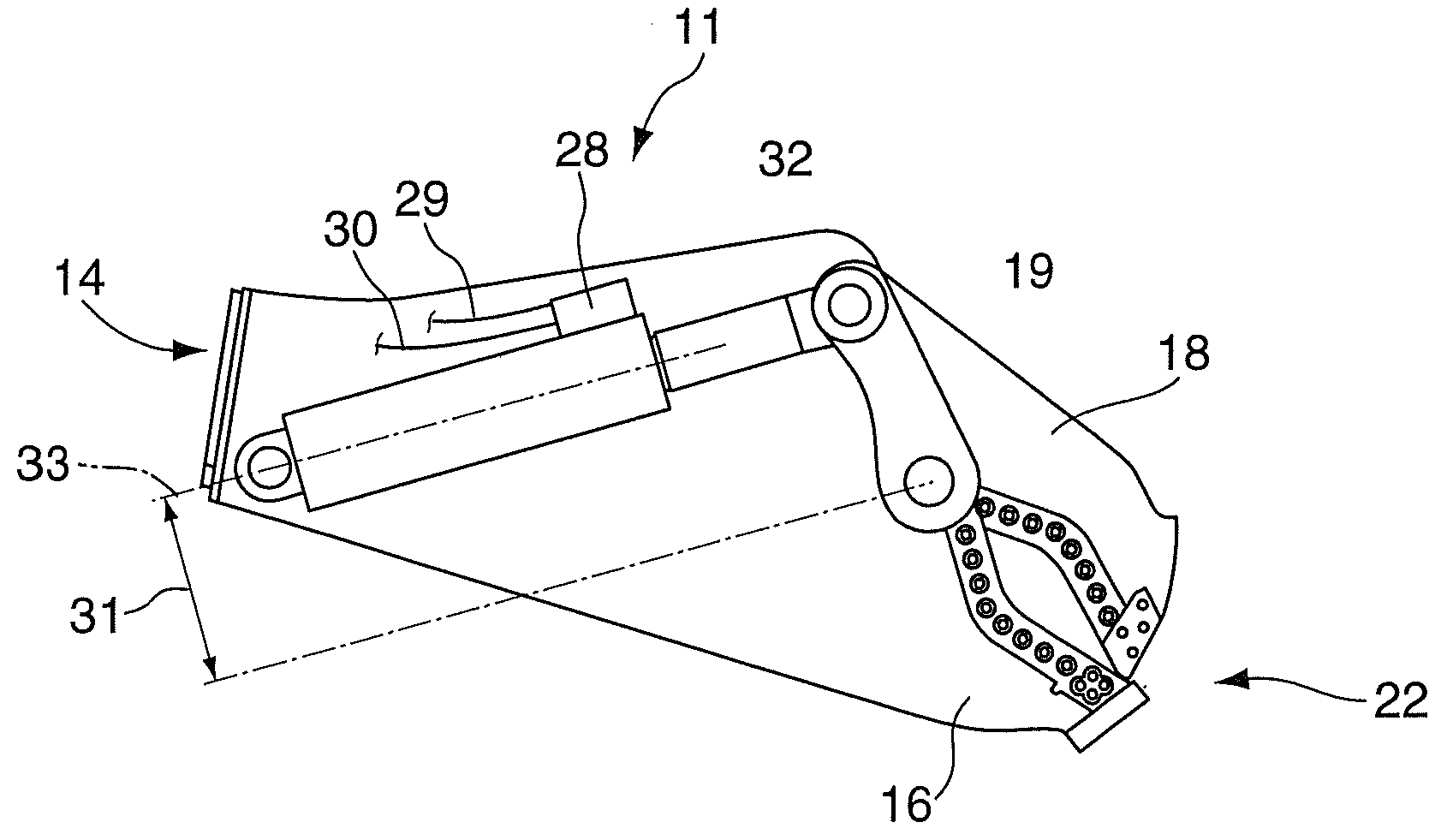

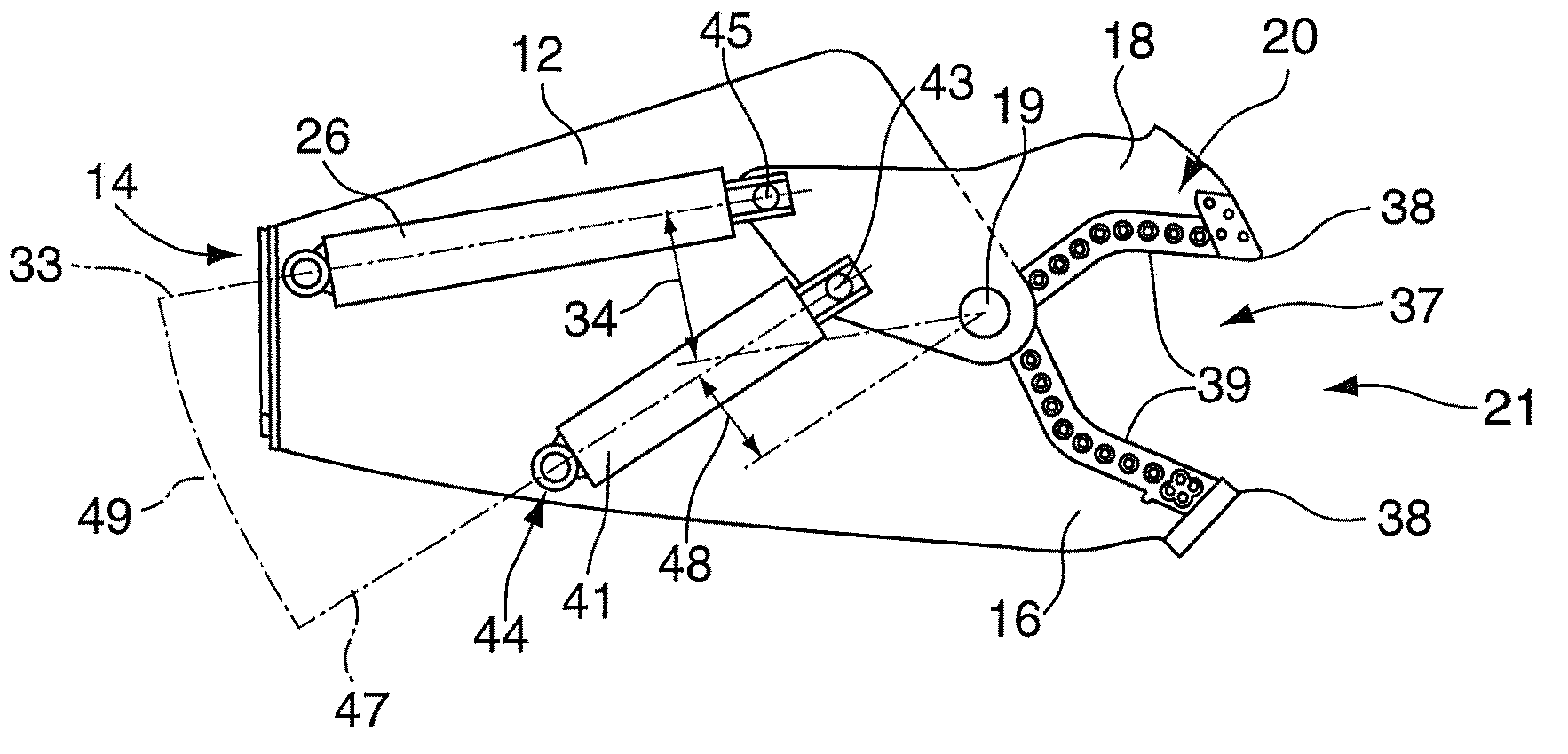

[0033] Figure 1a and Figure 1b A mountable device 11 known from DE 600 21 539 T2 is shown. It is incorporated by reference in its entirety into this disclosure. The installable hydraulic device 11 comprises a housing 12 having an engagement interface 14 by means of which said installable hydraulic device 11 can be attached by a simple alternative to a boom not shown in further detail in the figures and attached to the hydraulic system of a loading device not shown in further detail, such as a skid loader or an excavator. The housing 12 includes a fixed lower jaw 16 or fixed lower protrusion and a hinged upper jaw 18 or hinged upper protrusion. The upper jaw 18 is pivotable about a bearing shaft 19 which is arranged in a fixed manner on the housing 12 . Alternatively, unlike the embodiment described above, the jaw 16 may be pivotable about said bearing shaft 19 like the upper jaw 18 .

[0034] Both the upper and lower jaws 18 , 16 are provided with a cutting tool 20 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com