Manufacturing method of high-purity copper targets

A production method and high-purity technology, applied in the field of high-purity copper target production, can solve the problems of no high-purity copper target rolling and heat treatment, high cost and technical difficulty of high-purity target, and avoid internal crystals. The effect of uneven grain size, improving production efficiency, and preventing internal grain changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

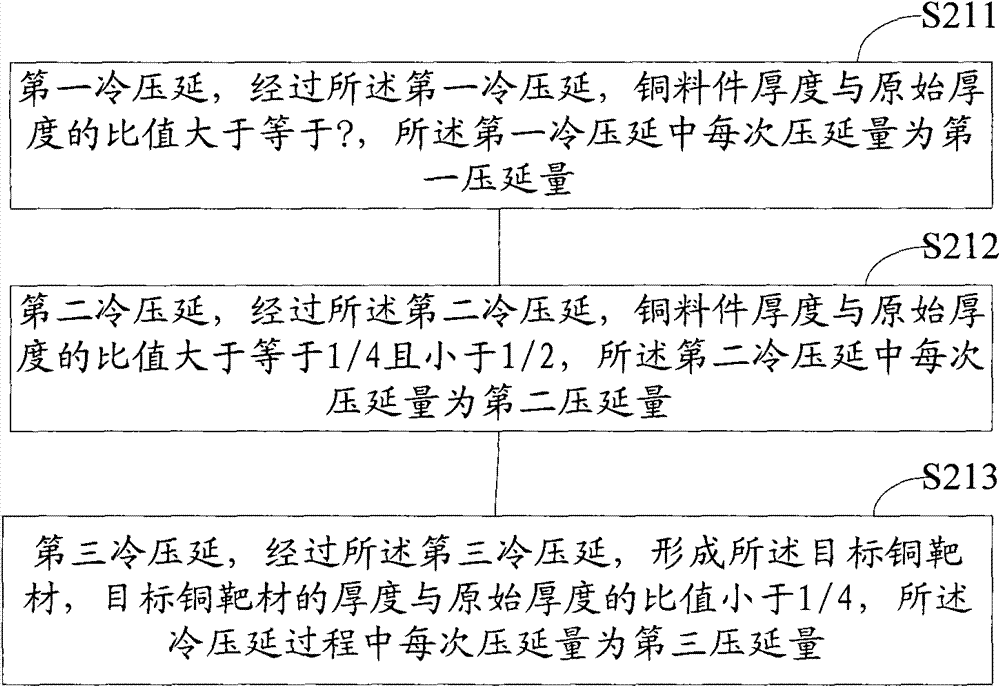

[0038] The inventors of the present invention found that the copper material is generally a copper ingot extending in the thickness direction, and its size and internal crystal grains do not meet the requirements, and the size and internal crystal grains need to be cold-rolled to meet the requirements. The control of the amount of rolling during cold rolling has an effect on the size as well as the internal grain size. If the amount of rolling is too large, the thickness of the target copper target will be too small or the internal grains of the target copper target will change and fail to meet the requirements. During the rolling process, the uneven force on each point on the rolled surface of the copper material will cause the surface of the copper target to be uneven after rolling.

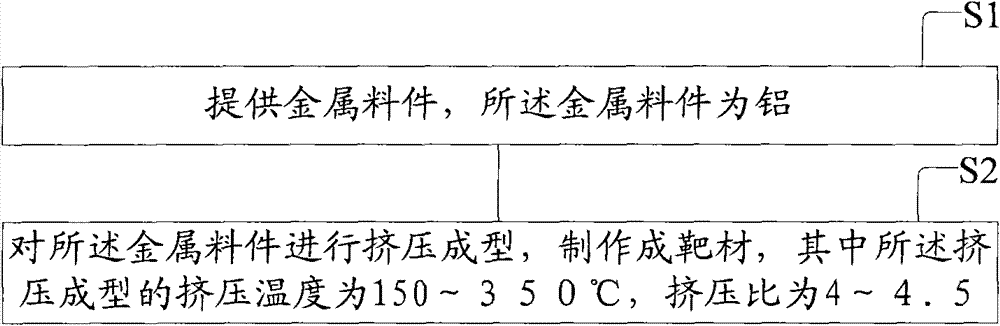

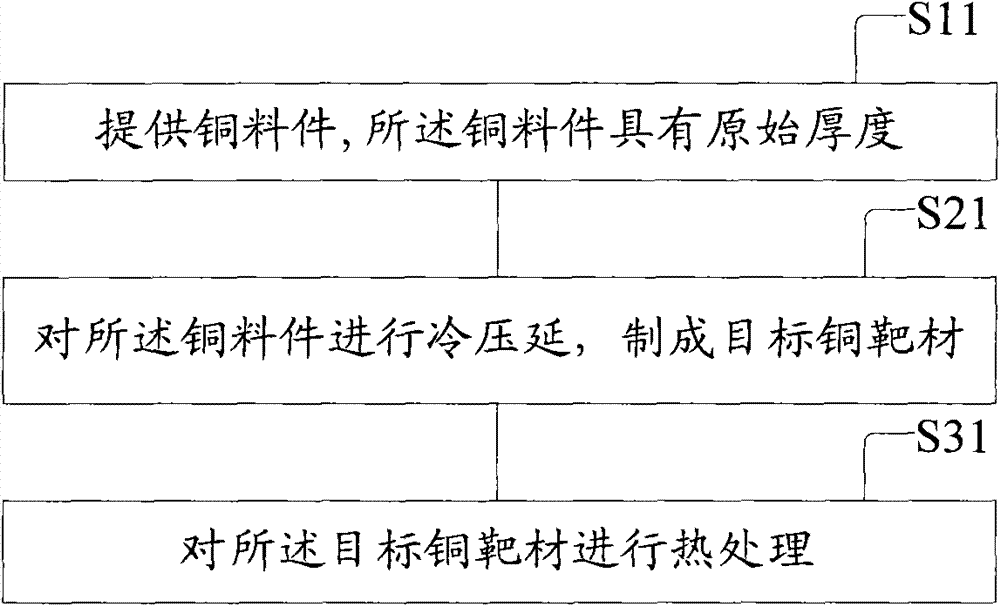

[0039] In view of the above problems, the inventors proposed a method for manufacturing a high-purity copper target. Such as figure 2 As shown, the method includes:

[0040] Step S21, provi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com