Thickened hanging piece for crossbeam

The technology of one beam and the other is applied in the field of thickened beams, which can solve problems such as broken teeth of beams, substandard force, inconvenient installation and disassembly, etc., to optimize product structure and reduce frictional resistance , Reduce the effect of stress

Inactive Publication Date: 2011-06-15

GUANGDONG WEITELONG TECH CO LTD

View PDF8 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the existing ordinary shelves mainly include bracket type and buckle type. Among them, bracket type shelves are inconvenient to install and disassemble, so more and more people are willing to use buckle type shelves.

However, when the existing snap-fit racks are loaded and loaded, the key joint of the beam and the column is the hanging piece. Due to the influence of cost and processing equipment, when making the hanging piece, it is necessary to reduce the appearance material and reduce the weight. Thin hanging pieces are used to process the thickness of the steel plate to achieve the effect of reducing costs, but this will cause the force to fail to meet the standard, and it is prone to breakage of the hanging pieces of the beam

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

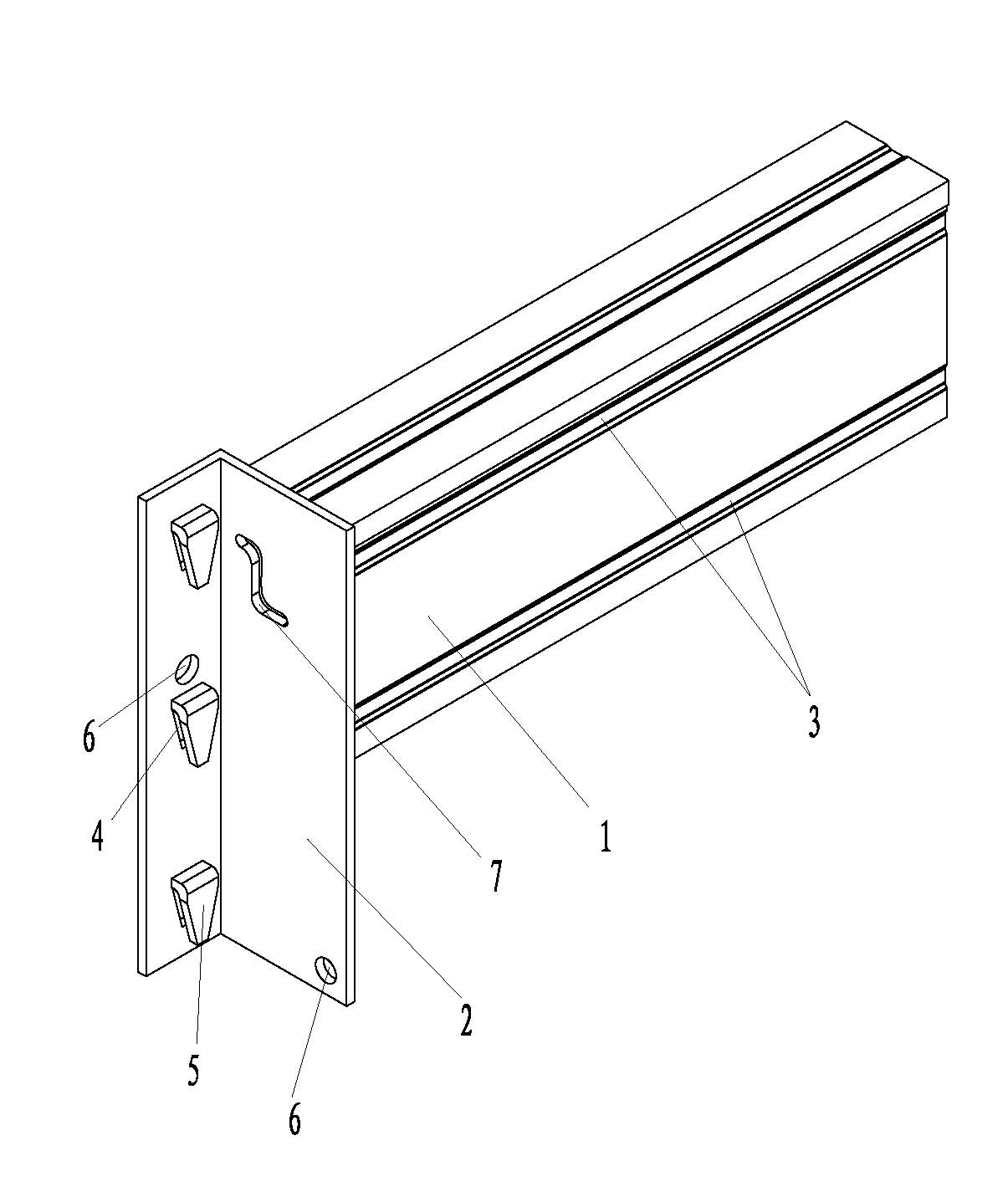

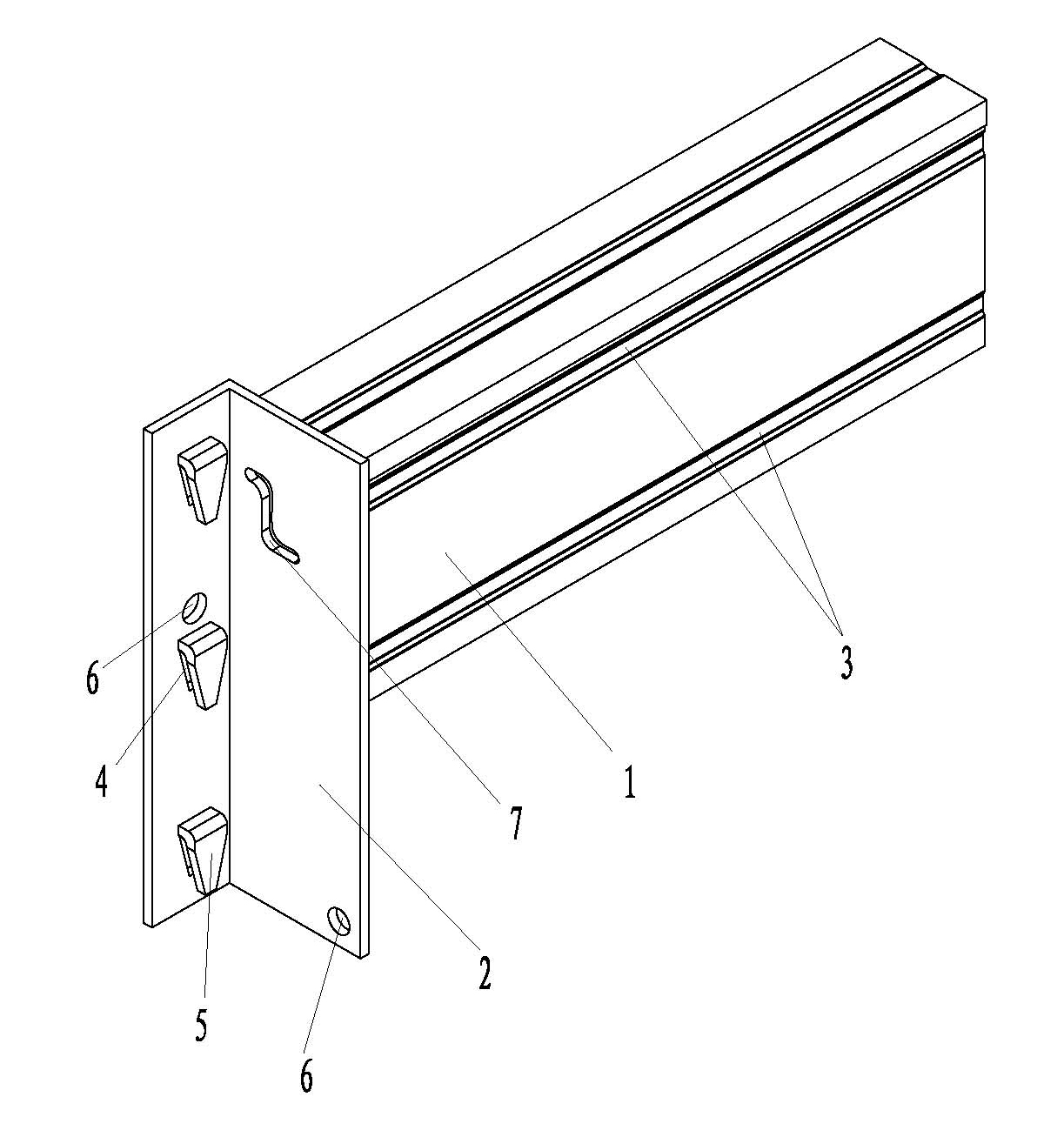

The invention relates to the technical field of goods shelf connection, in particular to a thickened hanging piece for a crossbeam. The hanging piece comprises a fastening plate, wherein, the section of the fastening plate is in an 'L' shape; one edge of the fastening plate is equipped with a hanging piece hole; the edge of the hanging piece hole is equipped with the hanging piece; and the width of one end of the hanging piece connected with the edge of the hanging piece hole is greater than that of a hanging end of the hanging piece. The thickened hanging piece has the beneficial effects that the hanging piece is set to be a shape with a big end and a small end, which increases biting force for fastening the hanging piece with an upright column or the crossbeam and meanwhile reduces frictional resistance so as to improve safety performance, reduce stress hidden danger and realize product structural optimization and promotion under the conditions of reasonable material selection and suitable cost; and hanging teeth of the hanging piece can be fully combined with stressed points of the upright column during the assembly process, which ensures that stress condition of the crossbeam reaches the standard within a design load-bearing range.

Description

A thickened hanging piece for beams technical field The invention relates to the technical field of shelf connection, in particular to a beam-thickened hanging piece. Background technique At present, the existing common shelves mainly include bracket type and snap-fit type. Among them, the installation and disassembly of bracket type shelves is inconvenient, so more and more people are willing to use snap-fit type shelves. However, when the existing snap-fit racks are loaded and loaded, the key joint of the beam and the column is the hanging piece. Due to the influence of cost and processing equipment, when making the hanging piece, it is necessary to reduce the appearance material and reduce the weight. Thin hanging pieces process the thickness of the steel plate to achieve the effect of reducing costs, but this will cause the force to fail to meet the standard, and it is prone to breakage of the hanging pieces of the beam. Contents of the invention The purpose ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A47F5/00

Inventor 徐隆久

Owner GUANGDONG WEITELONG TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com