Preparation method for three-dimensional network structure membrane electrode for direct methanol fuel cell

A methanol fuel cell and network structure technology, applied in battery electrodes, structural parts, circuits, etc., can solve the problems of peeling off from the proton exchange membrane, reducing the catalyst usage rate, MEA dehydration, etc., to increase the active surface area, reduce Internal resistance, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Membrane preparation and pretreatment. Nafion 115 membrane at 5% H by volume 2 o 2 Treat in aqueous solution at 80°C for 1 hour, then treat in double-distilled water at 80°C for 1 hour, and then use 0.5 mol L at 80°C -1 h 2 SO 4 Aqueous solution treatment, and finally placed in double distilled water at 80°C for 1 hour, then put the Nafion membrane in double distilled water for later use.

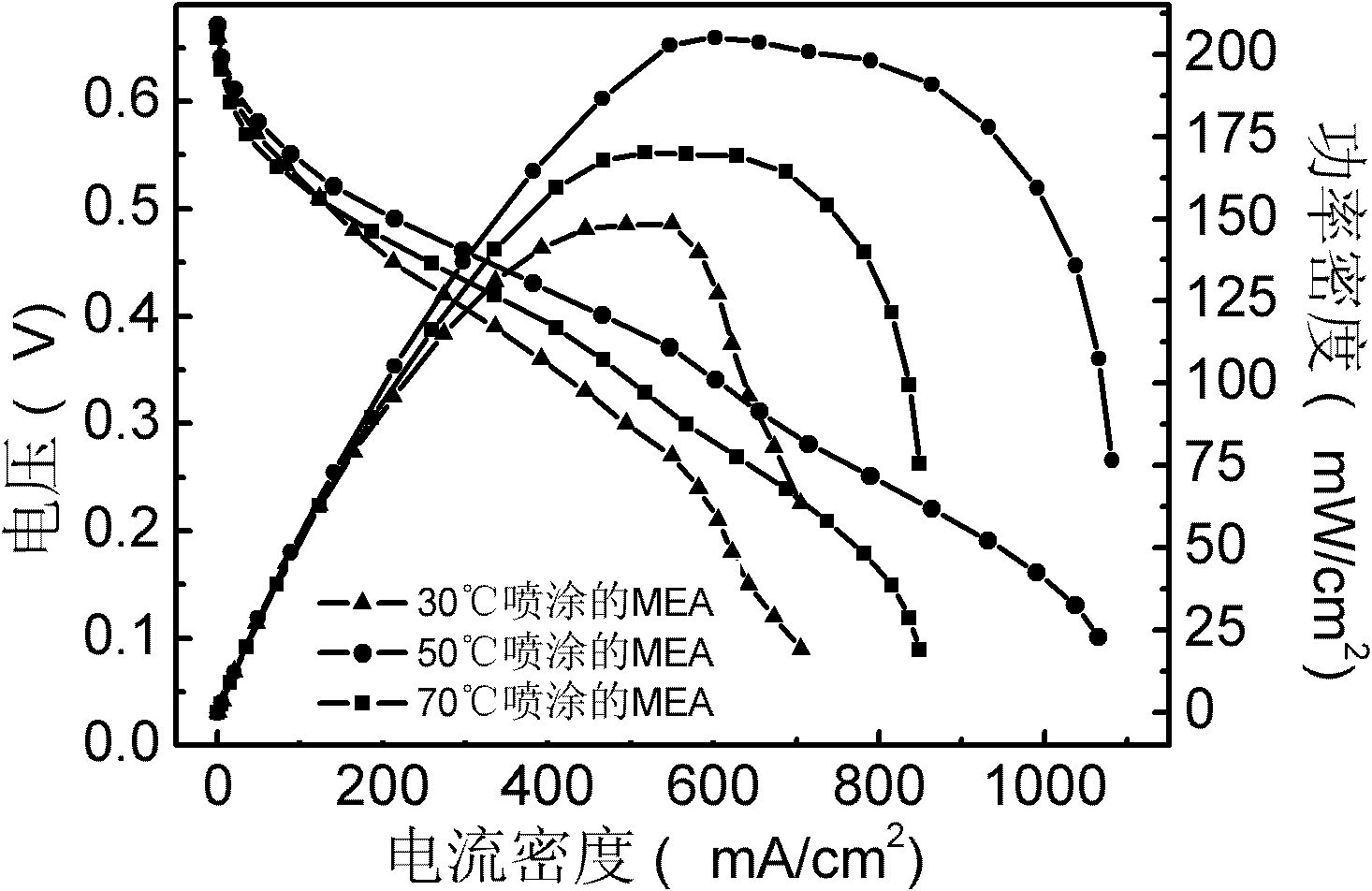

[0034] 2. Preparation of catalyst slurry and preparation of catalytic layer. Choose 4mg / cm for cathode and anode respectively 2 Pt black and 4mg / cm 2 The PtRu black catalyst, respectively using 0.008mL / cm 2 and 0.013 mL / cm 2 5 wt % Nafion solution as binder, using 0.222mL / cm 2 and 0.235 mL / cm 2 propanol as a dispersant. The glove box was evacuated and filled with Ar gas. The catalyst was weighed in the glove box, the slurry was prepared, and the catalyst slurry was prepared by ultrasonic dispersion using an ultrasonic cell disruptor.

[0035] The flat heater with PTF...

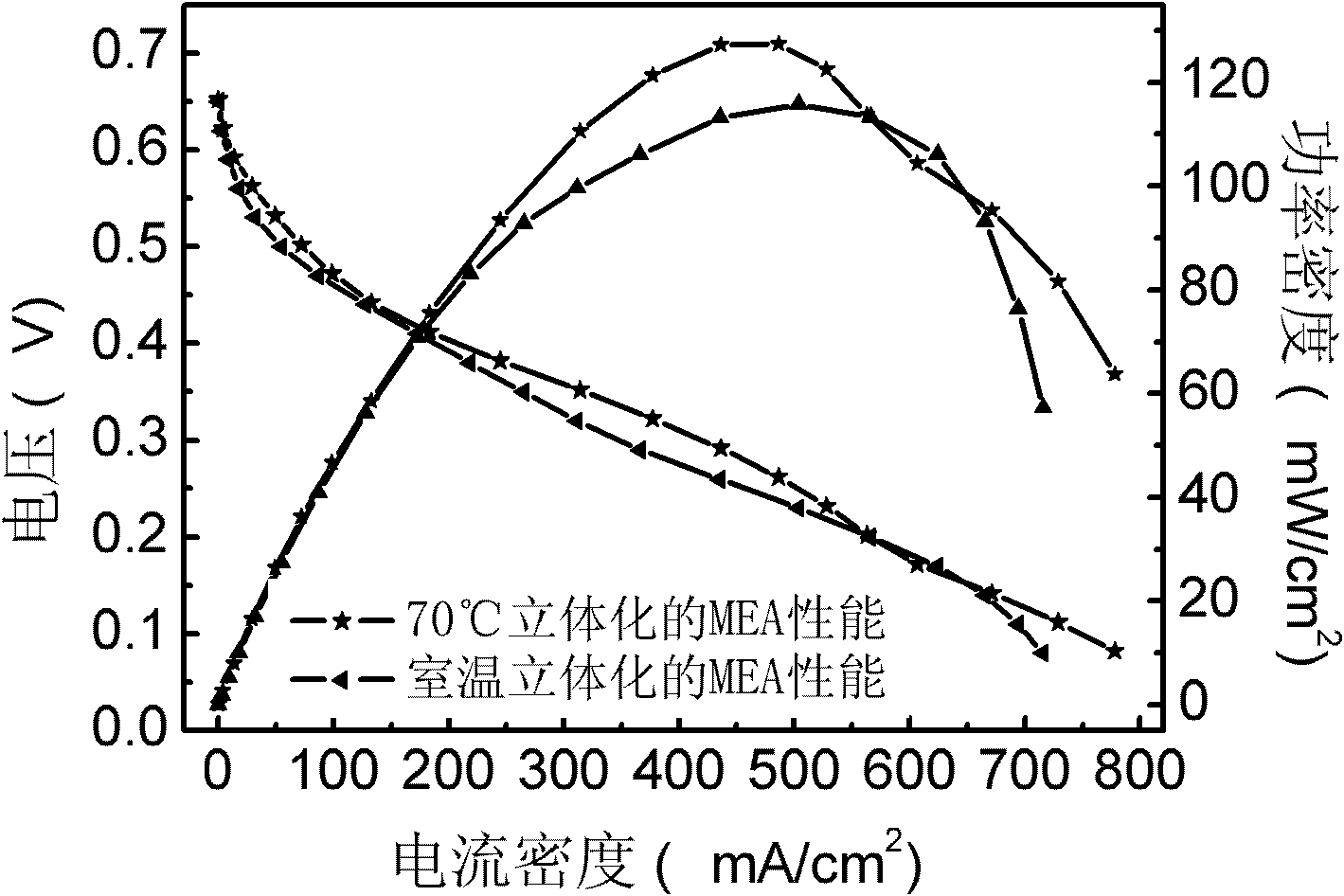

Embodiment 2

[0042] 1. Membrane preparation and pretreatment. Nafion 115 membrane at 5% H by volume 2 o 2 Treat in aqueous solution at 80°C for 1 hour, then treat in double-distilled water at 80°C for 1 hour, and then use 0.5 mol L at 80°C -1 h 2 SO 4 Aqueous solution treatment, and finally placed in double distilled water at 80°C for 1 hour, then put the Nafion membrane in double distilled water for later use.

[0043] 2. Preparation of catalyst slurry and preparation of catalytic layer. Choose 2mg / cm for cathode and anode respectively 2 Pt black and 4mg / cm 2 The PtRu black catalyst, respectively using 0.004mL / cm 2 and 0.013 mL / cm 2 The 5 wt % Nafion solution was used as the binder, respectively using 0.111mL / cm 2 and 0.235 mL / cm 2 propanol as a dispersant. The glove box was evacuated and filled with N 2 gas. The catalyst was weighed in the glove box, the slurry was prepared, and the catalyst slurry was prepared by ultrasonic dispersion using an ultrasonic cell disruptor.

...

Embodiment 3

[0050] 1. Membrane preparation and pretreatment. Nafion 115 membrane at 5% H by volume 2 o 2 Treat in aqueous solution at 80°C for 1 hour, then treat in double-distilled water at 80°C for 1 hour, and then use 0.5 mol L at 80°C -1 h 2 SO 4 Aqueous solution treatment, and finally placed in double distilled water at 80°C for 1 hour, then put the Nafion membrane in double distilled water for later use.

[0051] 2. Preparation of catalyst slurry and preparation of catalytic layer. Choose 3mg / cm for cathode and anode respectively 2 Pt black and 4mg / cm 2 The PtRu black catalyst, respectively using 0.006mL / cm 2 and 0.013 mL / cm 2 5 wt % Nafion solution as binder, using 0.167mL / cm 2 and 0.235 mL / cm 2 propanol as a dispersant. The glove box was evacuated and filled with N 2 gas. The catalyst was weighed in the glove box, the slurry was prepared, and the catalyst slurry was prepared by ultrasonic dispersion using an ultrasonic cell disruptor.

[0052] The flat heater with P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com