Iron phthalocyanine prepolymer/Fe3O4 nanometer hybrid magnetic material and preparation method thereof

A magnetic material, iron phthalocyanine pre-preparation technology, applied in the direction of magnetism, nanotechnology, nanotechnology, etc. of organic materials/organic magnetic materials, to achieve the effects of stable performance, rapid and convenient separation, and stable reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

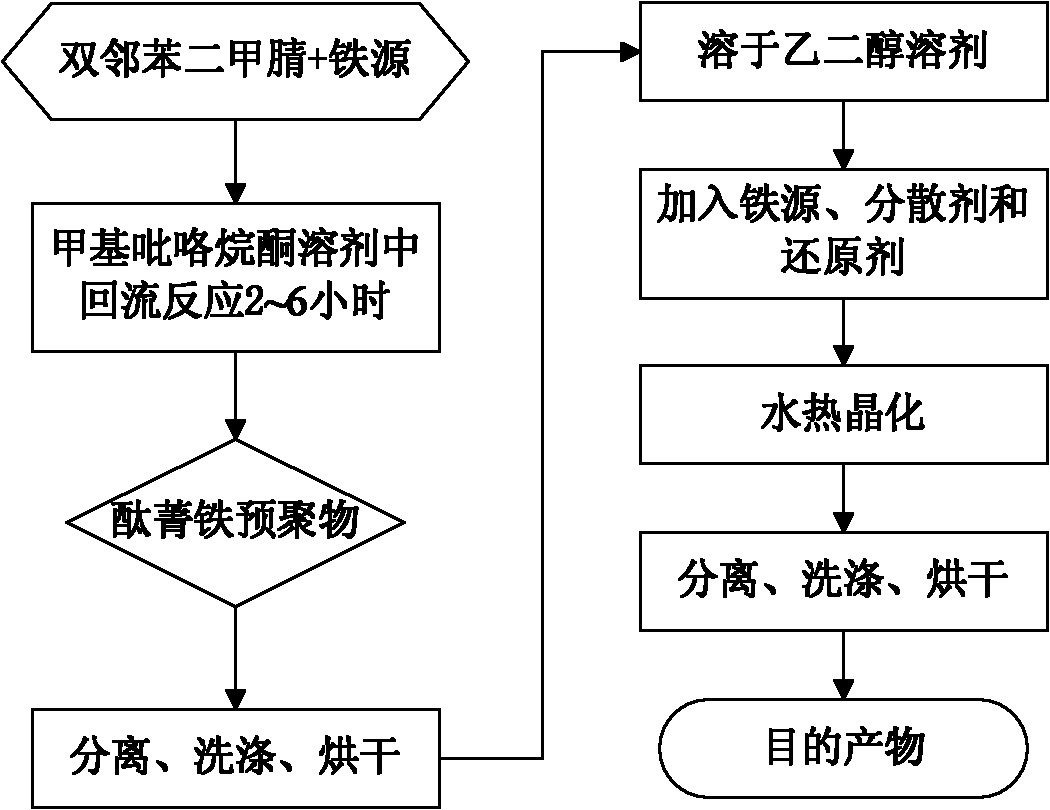

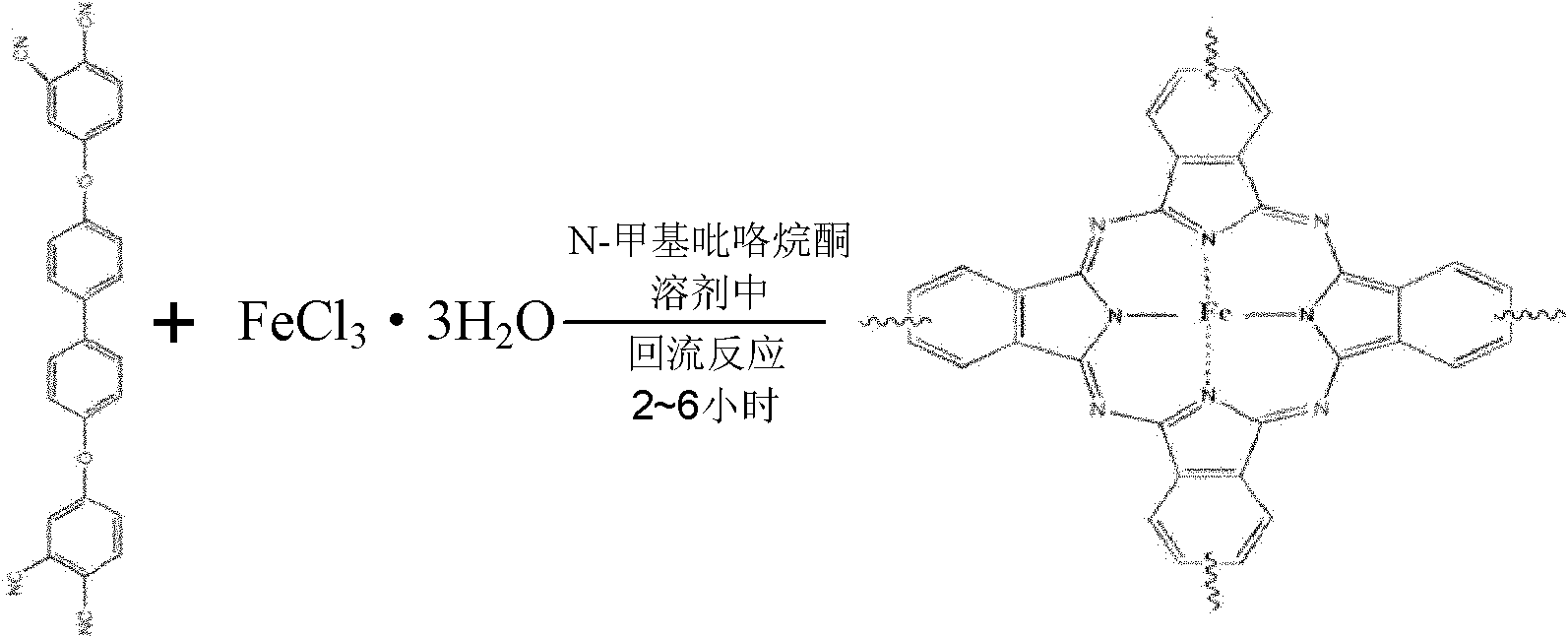

[0038] Step 1. Weigh 10 grams of diphenol-type diphthalonitrile monomer, 0.2-0.6 grams of FeCl 3 ·3H 2 O, put it into a three-necked bottle, pour 10ml of N-methylpyrrolidone as a solvent; raise the temperature and continue the reflux reaction for 2 to 6 hours after the solution changes color.

[0039] Step 2. Pour the solution into water, filter, wash the filtered solid with deionized water for 2 to 3 times, dry and collect.

[0040] Step 3. Weigh 1.0 to 4.0 grams of the sample collected in step 2 and dissolve it in 200ml of ethylene glycol solution. After it is completely dissolved, the solution is cooled to room temperature, and 6.75 grams of FeCl is added in turn. 3 ·3H 2 O, 5.0 grams of PEG2000, 18 grams of crystalline sodium acetate, stirred and reacted for 2 hours.

[0041] Step 4. Transfer the solution obtained in step 3 to a crystallization kettle, and crystallize at 200° C. for 4 hours. Among them, the addition of prepolymer has no obvious effect on the formation ...

Embodiment 2

[0045] Step 1. Weigh 10 grams of diphenol-type diphthalonitrile monomer, 0.2-0.6 grams of FeCl 3 ·3H 2 O, put into a three-necked bottle, and pour 10ml of N-methylpyrrolidone into it as a solvent. Raise the temperature to 200°C, and continue the reflux reaction for 2 to 6 hours after the solution changes color.

[0046] Step 2. Pour the solution into water, filter, wash the filtered solid with deionized water for 2 to 3 times, dry and collect.

[0047] Step 3. Weigh 1.0 to 4.0 grams of the sample collected in step 2 and dissolve it in 200ml of ethylene glycol solution. After it is completely dissolved, the solution is cooled to room temperature, and 6.75 grams of FeCl is added in turn. 3 ·3H 2 O, 5.0 grams of PEG2000, 18 grams of crystalline sodium acetate, stirred and reacted for 2 hours.

[0048] Step 4. Transfer the solution obtained in step 3 to a crystallization kettle, and crystallize at 200° C. for 8 hours. Among them, the addition of prepolymer has no obvious effe...

Embodiment 3

[0053] Step 1. Weigh 10 grams of diphenol-type diphthalonitrile monomer, 0.2-0.6 grams of FeCl 3 ·3H 2 O, put into a three-necked bottle, and pour 10ml of N-methylpyrrolidone into it as a solvent. After the temperature was raised and the color of the solution changed, the reflux reaction was continued for 2 to 6 hours.

[0054] Step 2. Pour the solution into water, filter, wash the filtered solid with deionized water for 2 to 3 times, dry and collect.

[0055] Step 3. Weigh 1.0 to 4.0 grams of the sample collected in step 2 and dissolve it in 200ml of ethylene glycol solution at 200°C. After it is completely dissolved, the solution is cooled to room temperature, and 6.75 grams of FeCl is added in turn. 3 ·3H 2 O, 5.0 grams of PEG2000, 18 grams of crystalline sodium acetate, stirred and reacted for 2 hours.

[0056] Step 4. Transfer the solution obtained in step 3 to a crystallization kettle, and crystallize at 200° C. for 15 hours. Among them, the addition of prepolymer h...

PUM

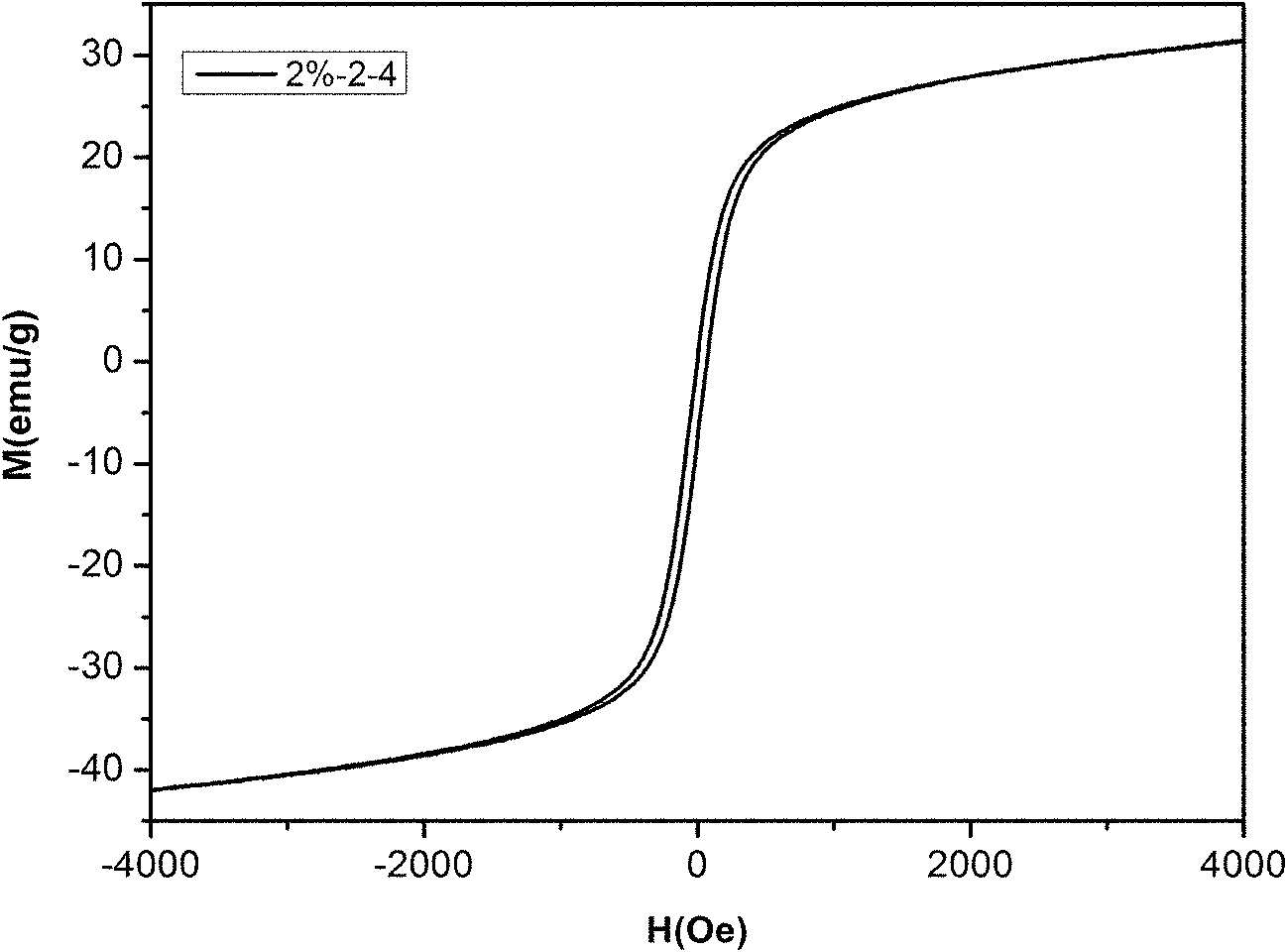

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com