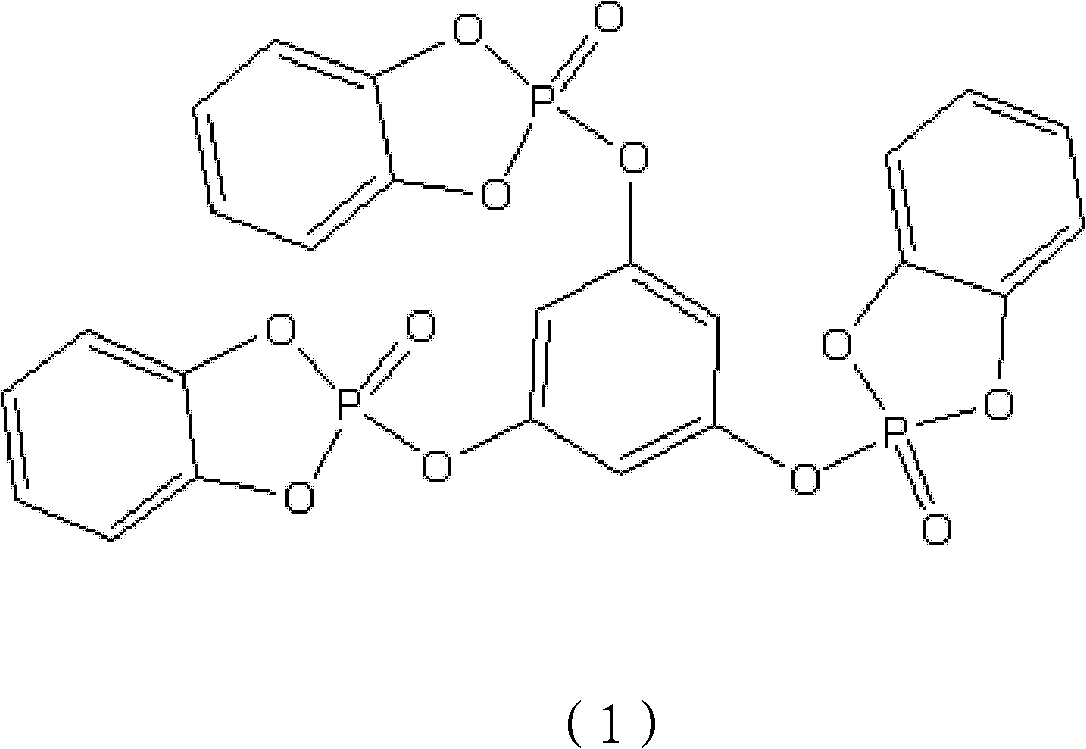

Novel fire retardant tri(1,3-dioxa-2-phospho hetero-2-oxo-1,2-indane) m-cresyl phosphate and preparation method thereof

A technology of phloroglucinol phosphate and indene dihydrogenate is applied in the field of phloroglucinol triphosphate and its preparation, which can solve the problems of high cost and poor flame retardant effect, and achieves low cost and flame retardant effect. Good effect and strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Clean and dry all the glass instruments used in the experiment. Get 1.10 grams (0.01mol) of catechol and put it into a 250ml three-necked flask, then dissolve the catechol with 5ml of chloroform. Take 5.05 g (0.05 mol) of triethylamine and 4.56 g (0.03 mol) of phosphorus oxychloride respectively in a constant pressure dropping funnel, and slowly drop them into a three-necked flask after heating to 70°C. After the dropwise addition was completed, the reaction was continued for 1 hour. Distillation under reduced pressure was then carried out. Below 65°C, distill under reduced pressure for 30 minutes to remove excess phosphorus oxychloride and add 0.50 g (0.004 mol) of phloroglucinol and 3 ml of chloroform while hot. Then take 3.03 g (0.04 mol) of triethylamine and 3 ml of chloroform in the dropping funnel, slowly add dropwise, control the temperature at 40 degrees, and react for 5 hours. Below 70°C, distill under reduced pressure for 45 minutes until the remaining prod...

Embodiment 2

[0028] Clean and dry all the glass instruments used in the experiment. Get 1.10 grams (0.01mol) of catechol and put it into a 250ml three-necked flask, then dissolve the catechol with 6ml of chloroform. Take 8.08 g (0.08 mol) of triethylamine and 6.84 g (0.045 mol) of phosphorus oxychloride respectively in a constant pressure dropping funnel, heat to 35 degrees and slowly drop them into a three-necked flask. After the dropwise addition was completed, the reaction was continued for 4 hours. Distillation under reduced pressure was then carried out. Below 100°C, distill under reduced pressure for 10 minutes to remove excess phosphorus oxychloride and add 1.26 g (0.01 mol) of phloroglucinol and 4 ml of chloroform while hot. Then take 2.02 g (0.02 mol) of triethylamine and 4 ml of chloroform in the dropping funnel, slowly add dropwise, control the temperature at 60 degrees, and react for 3 hours. The temperature was controlled below 70 degrees, and the distillation under reduced...

Embodiment 3

[0030] Clean and dry all the glass instruments used in the experiment. Get 1.10 grams (0.01mol) of catechol and put it into a 250ml three-necked flask, then dissolve the catechol with 5ml of chloroform. Take 2.02 g (0.02 mol) of triethylamine and 1.672 g (0.011 mol) of phosphorus oxychloride respectively in a constant pressure dropping funnel, and slowly drop them into a three-necked flask at a controlled temperature of 10°C. After the dropwise addition was completed, the reaction was continued for 10 hours. Distillation under reduced pressure was then carried out. Below 65°C, distill under reduced pressure for 30 minutes to remove excess phosphorus oxychloride and add 1.51 g (0.012 mol) of phloroglucinol and 3 ml of chloroform while hot. Then take 4.04 g (0.04 mol) of triethylamine and 5 ml of chloroform in the dropping funnel, slowly add dropwise, control the temperature at 10 degrees, and react for 9 hours. The temperature was controlled below 70 degrees, and the vacuum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com