AC generator for vehicle

A technology for alternators and vehicles, which is applied in the direction of electrical components, electromechanical devices, electric components, etc. It can solve the problems of reduced melting amount, reduced joint strength, and reduced vibration resistance, and achieves the effect of suppressing fatigue fracture and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, preferred embodiments of the stator of the automotive alternator according to the present invention will be described with reference to the drawings.

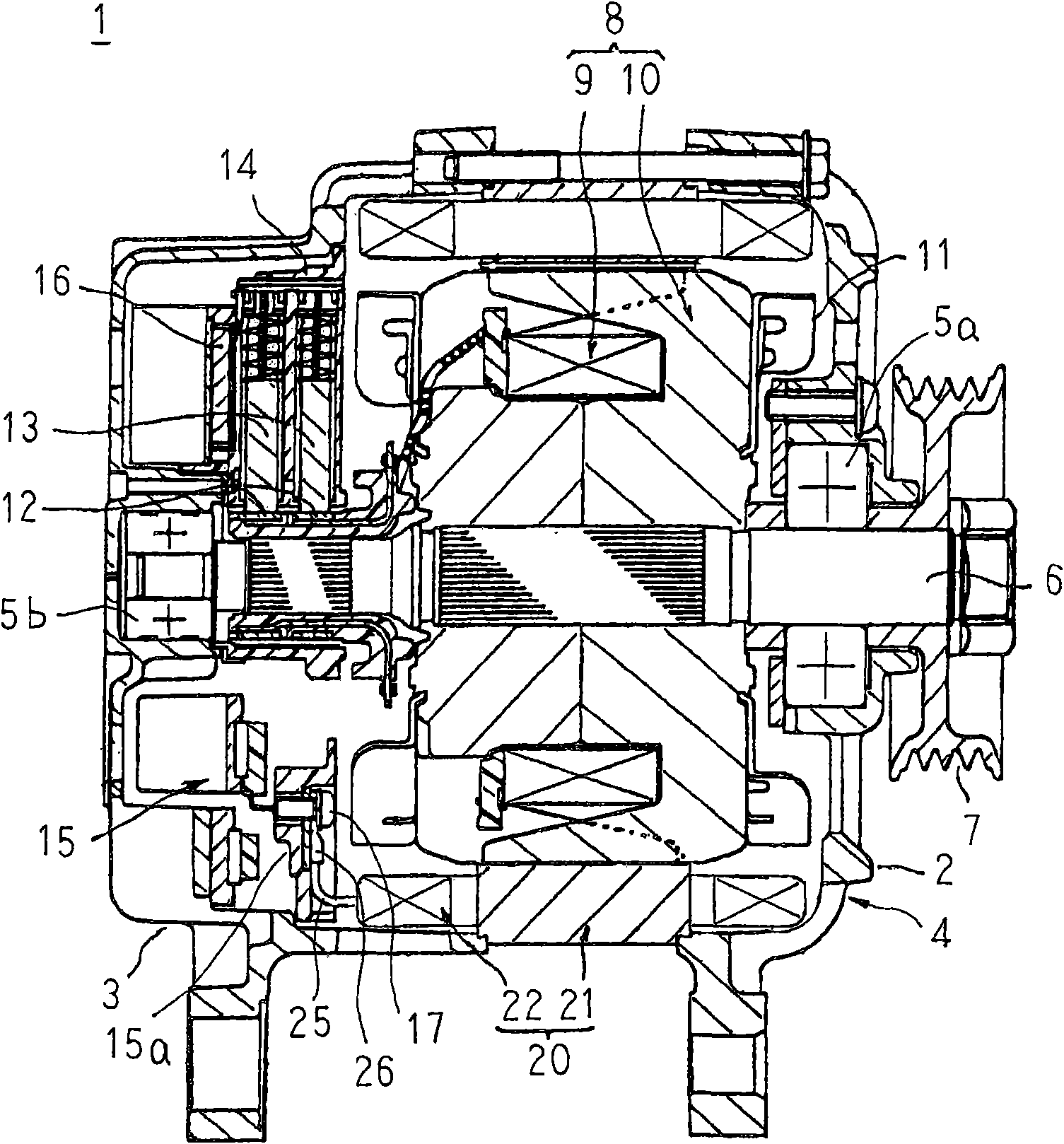

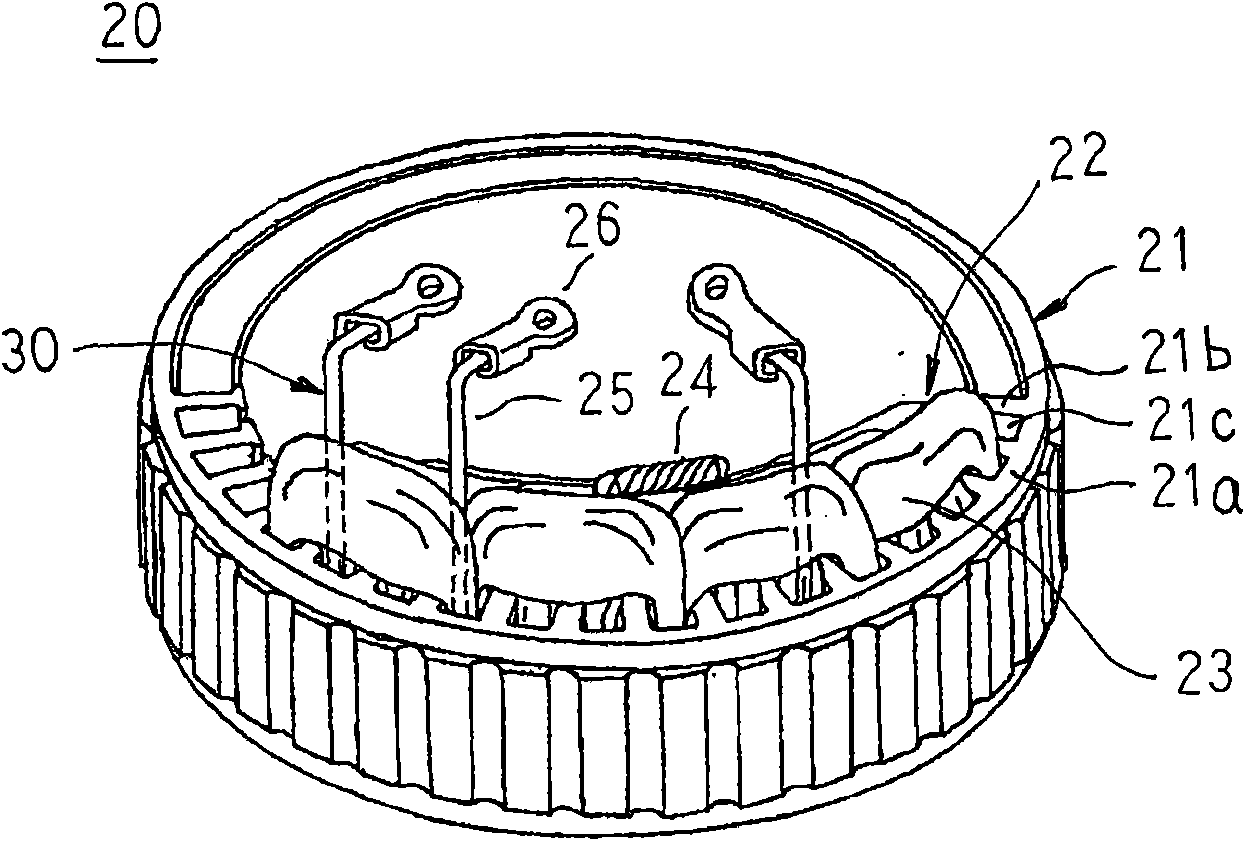

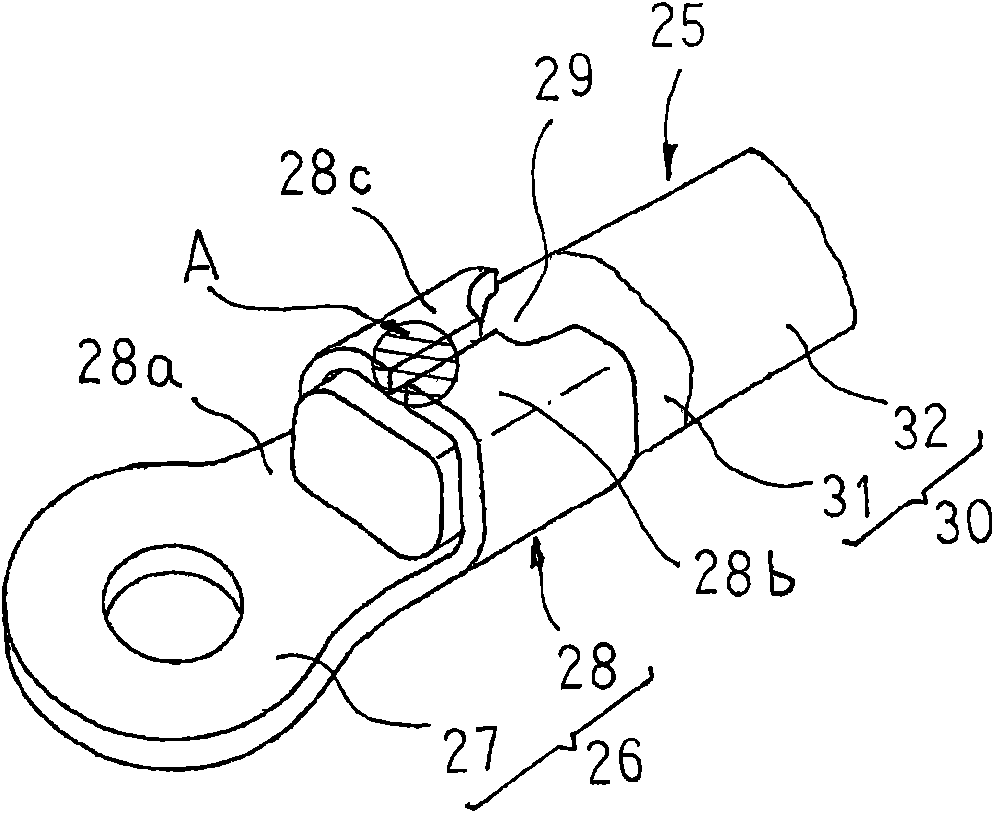

[0026] figure 1 is a longitudinal sectional view showing an automotive alternator according to an embodiment of the present invention, figure 2 is a perspective view showing a stator of an automotive alternator according to an embodiment of the present invention, image 3 It is a perspective view illustrating terminal processing of a lead-out conductor of a stator winding of an automotive alternator according to an embodiment of the present invention.

[0027] exist figure 1 Among them, the vehicle alternator 1 includes: a casing 4, which is composed of a bowl-shaped aluminum front bracket 2 and a rear bracket 3; a shaft 6, which is freely rotatably supported on the above-mentioned shaft through bearings 5a, 5b. Housing 4; pulley 7, the pulley 7 is fixed to the end of the shaft 6 extending toward the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com