Novel microplasma device containing floating electrode

A technology of micro-plasma and floating electrodes, which is applied in the direction of AC plasma display panels, solid cathode components, gas discharge tubes/containers, etc., to achieve the effects of fewer process steps, simple structural design, and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

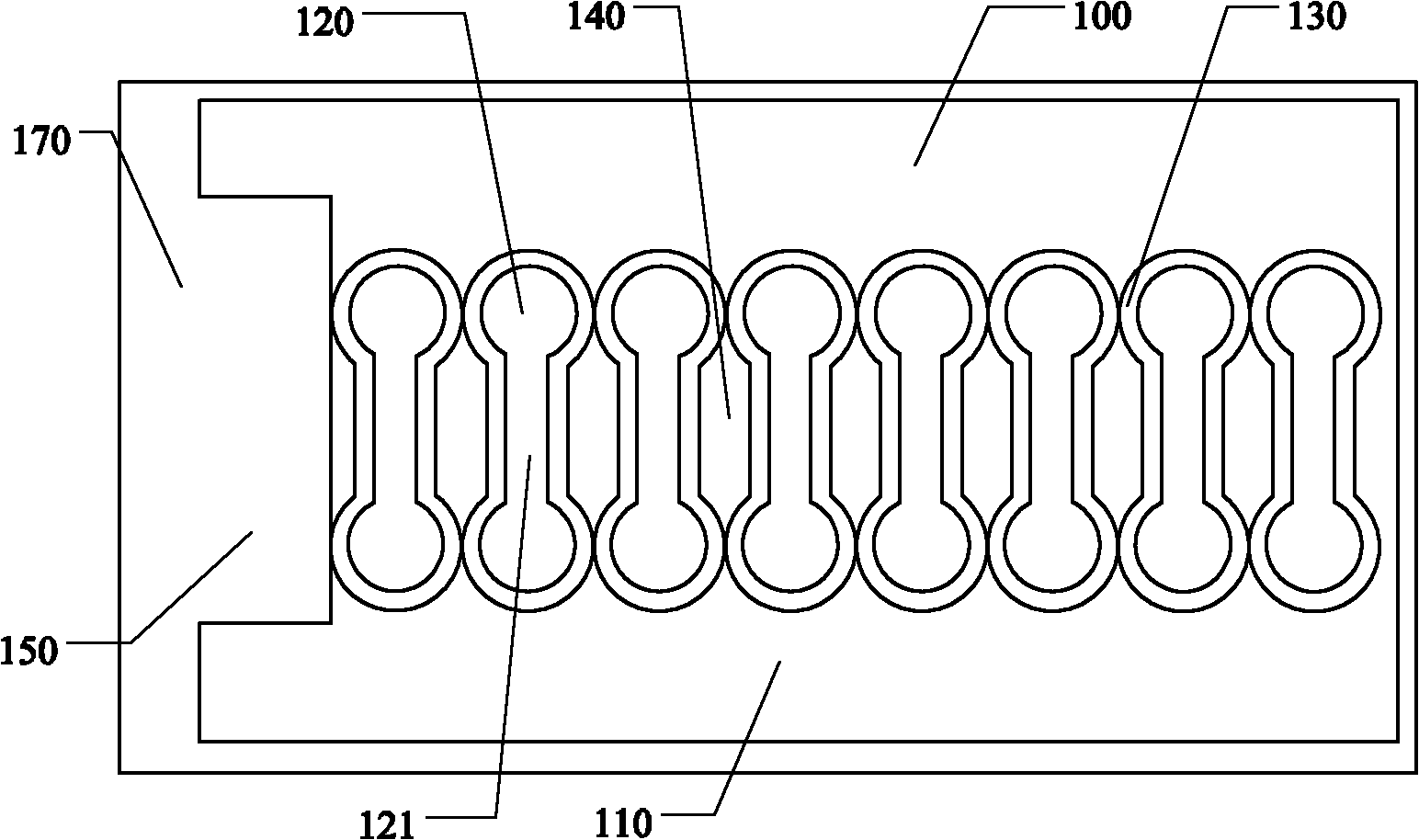

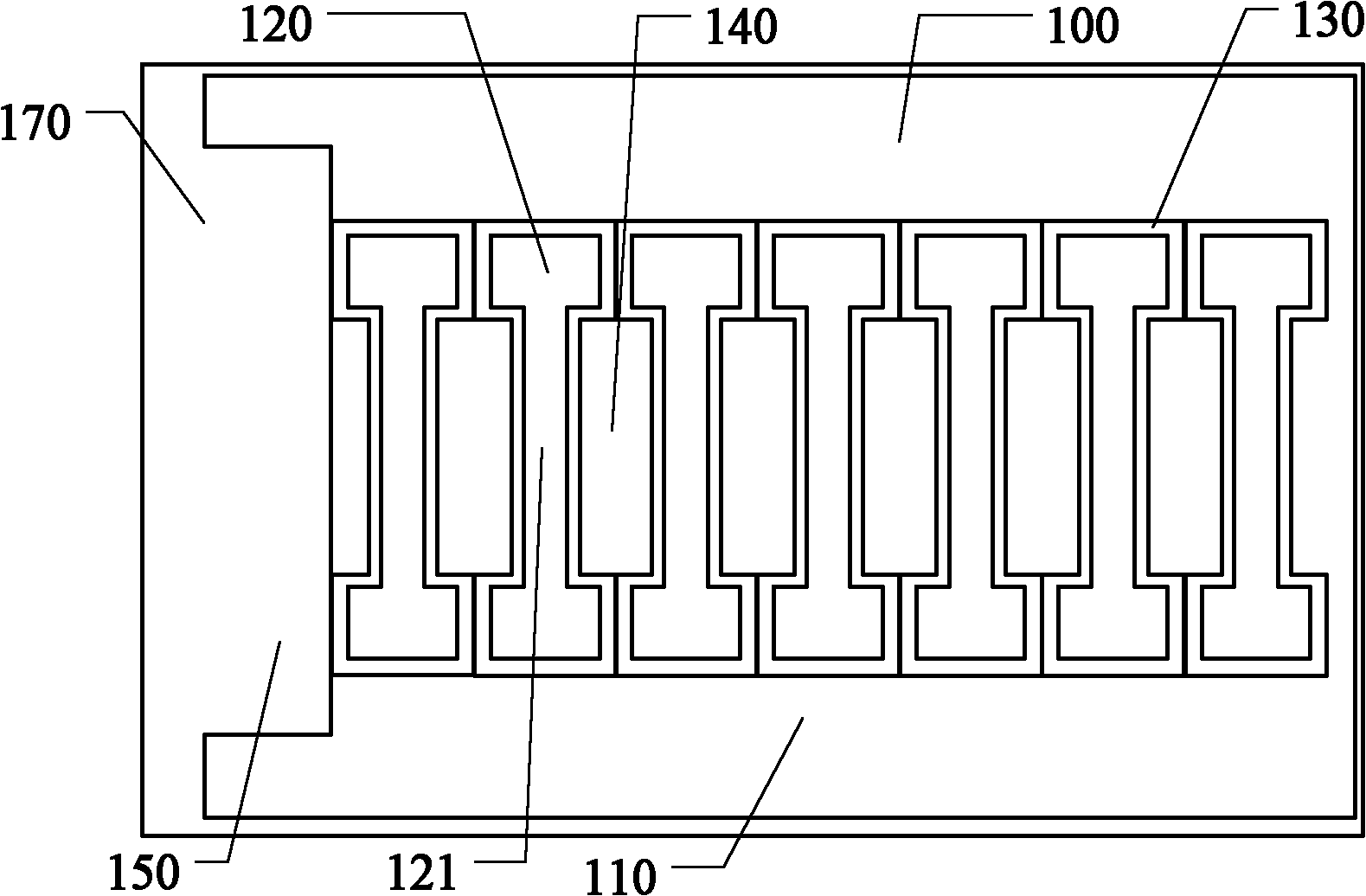

[0026] refer to figure 1 , first anneal the aluminum foil in the early stage to remove impurities and defects on the surface of the aluminum foil, so that the structure of the aluminum foil can be recrystallized, the grains can grow, and the crystallization performance can be improved. Then the annealed aluminum foil was treated in sequence: rinse with deionized water, ultrasonic degreasing with acetone, and rinse with deionized water to ensure the purity of the aluminum foil surface. Then, the aluminum foil is adhered to the rear substrate glass 170, and photolithography is carried out on the aluminum foil according to the previously prepared mask to carve a pattern similar to figure 1 The microcavity pattern window shown in , the pattern includes: round holes 120 at both ends and rectangular through grooves 121 . Afterwards, two electrochemical corrosions were carried out in hydrochloric acid solution to obtain the microcavity array. After the photolithographic etching pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com