Method for testing coating infrared emittance with spectral reflectance method

A technology of infrared emissivity and spectral reflectance, applied in the measurement of color/spectral characteristics, etc., can solve the problems of inability to eliminate errors, harsh test conditions, inability to measure emissivity, etc., to eliminate errors, loose test conditions, and test equipment. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

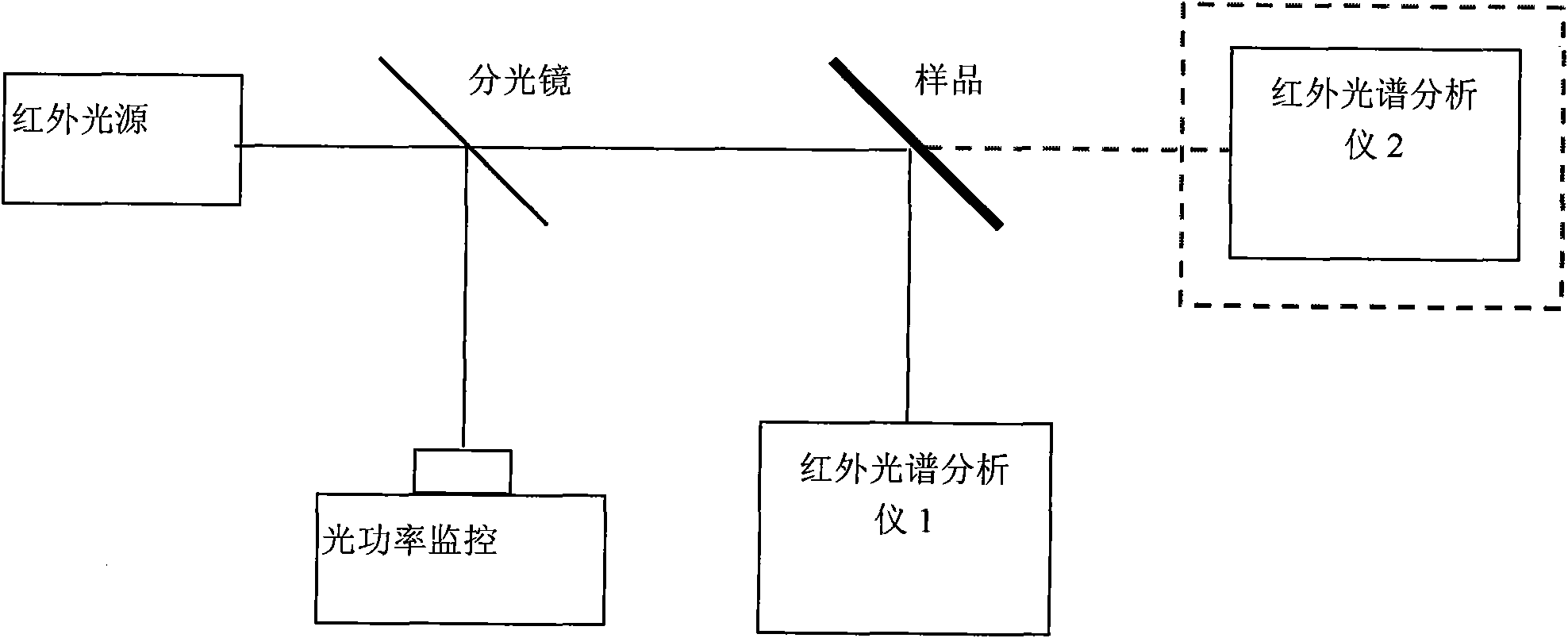

[0008] Below in conjunction with accompanying drawing and embodiment the present invention is described further; Utilize the method for spectral reflectance method testing coating infrared emissivity, it is characterized in that: test system is made up of infrared light source, multifunctional infrared grating spectrum analyzer, computer; Wherein The infrared grating spectrometer analyzer is composed of a grating monochromator, a receiving unit, a scanning system, an electronic amplifier, an A / D acquisition unit, and a computer; the incident slit and the outgoing slit of the spectrometer are all value slits, and the width range is 0-2mm Continuously adjustable;

[0009] The specific steps of the detection are as follows: the light emitted by the infrared light source is divided into two paths after passing through the beam splitter, one path is used as the measurement beam; the other path is used as the reference beam; the known infrared reflectance ρ 0 The standard sample of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com