Leak detection equipment

A kind of equipment and leak detection technology, which is applied in the direction of detecting the appearance of fluid at the leakage point and using liquid/vacuum degree to measure the liquid tightness, etc., which can solve the problems of special purpose, high manufacturing cost, and difficulty in judging the specific defect position of the workpiece, etc. , to achieve the effect of interchangeability, low cost and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

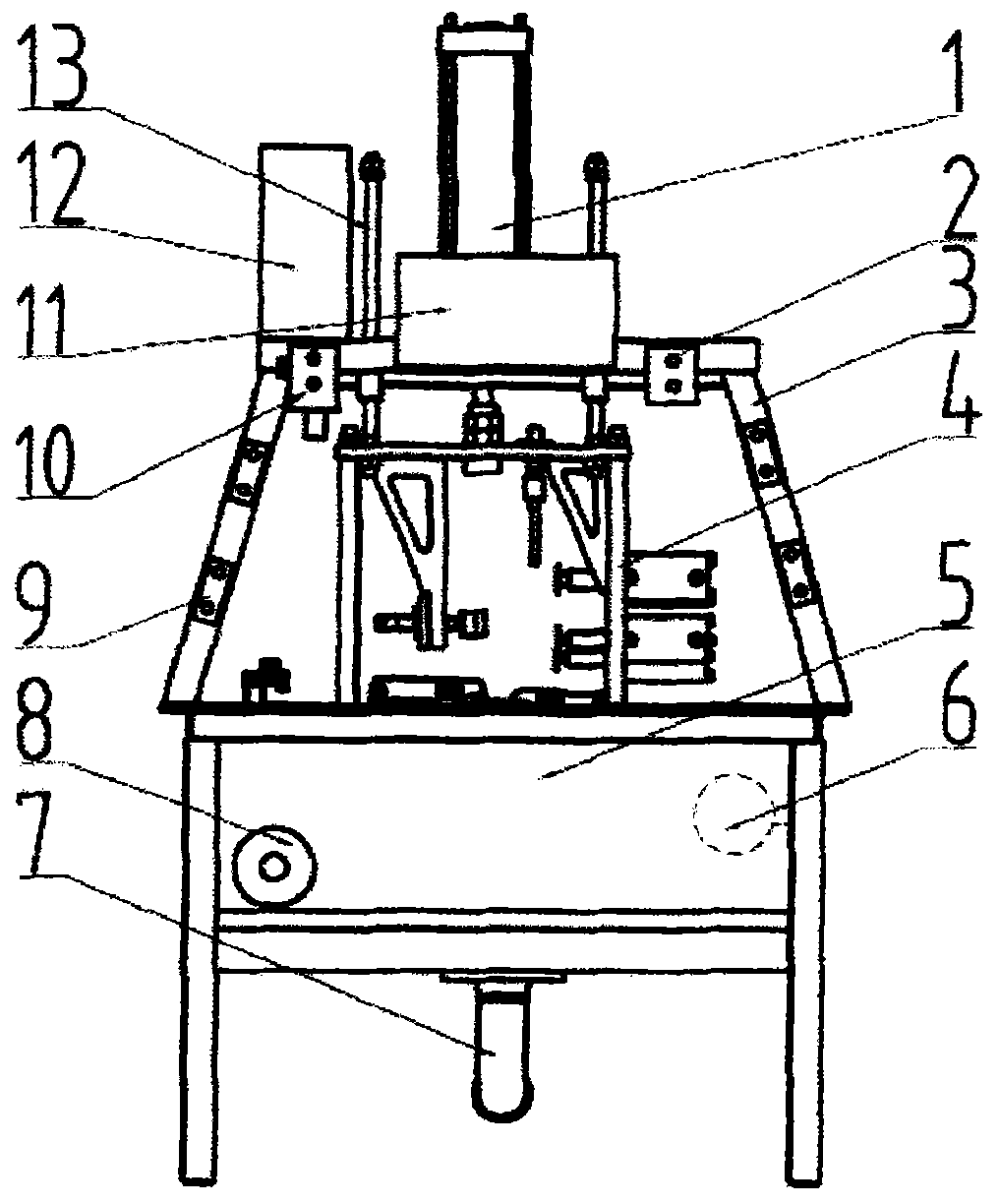

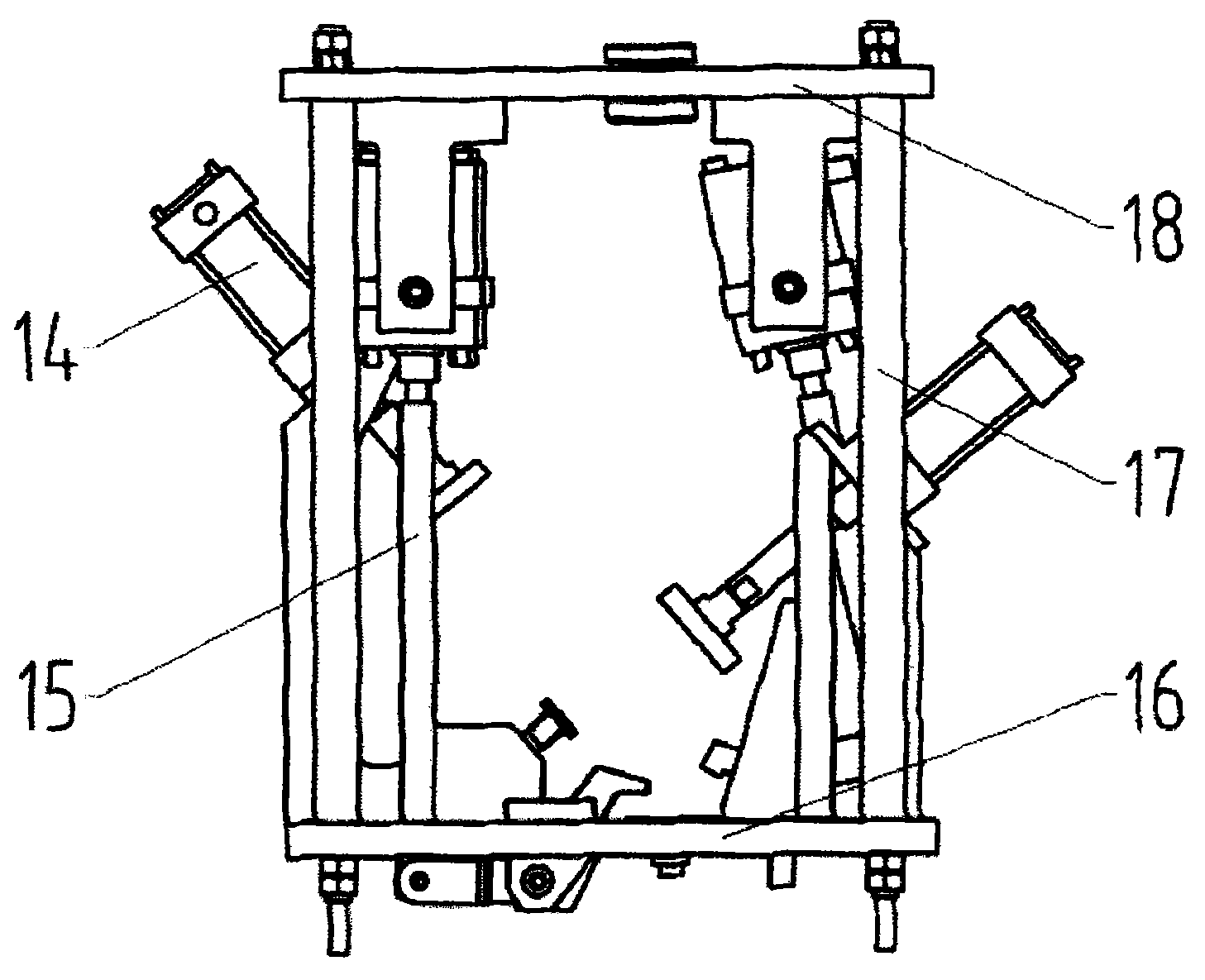

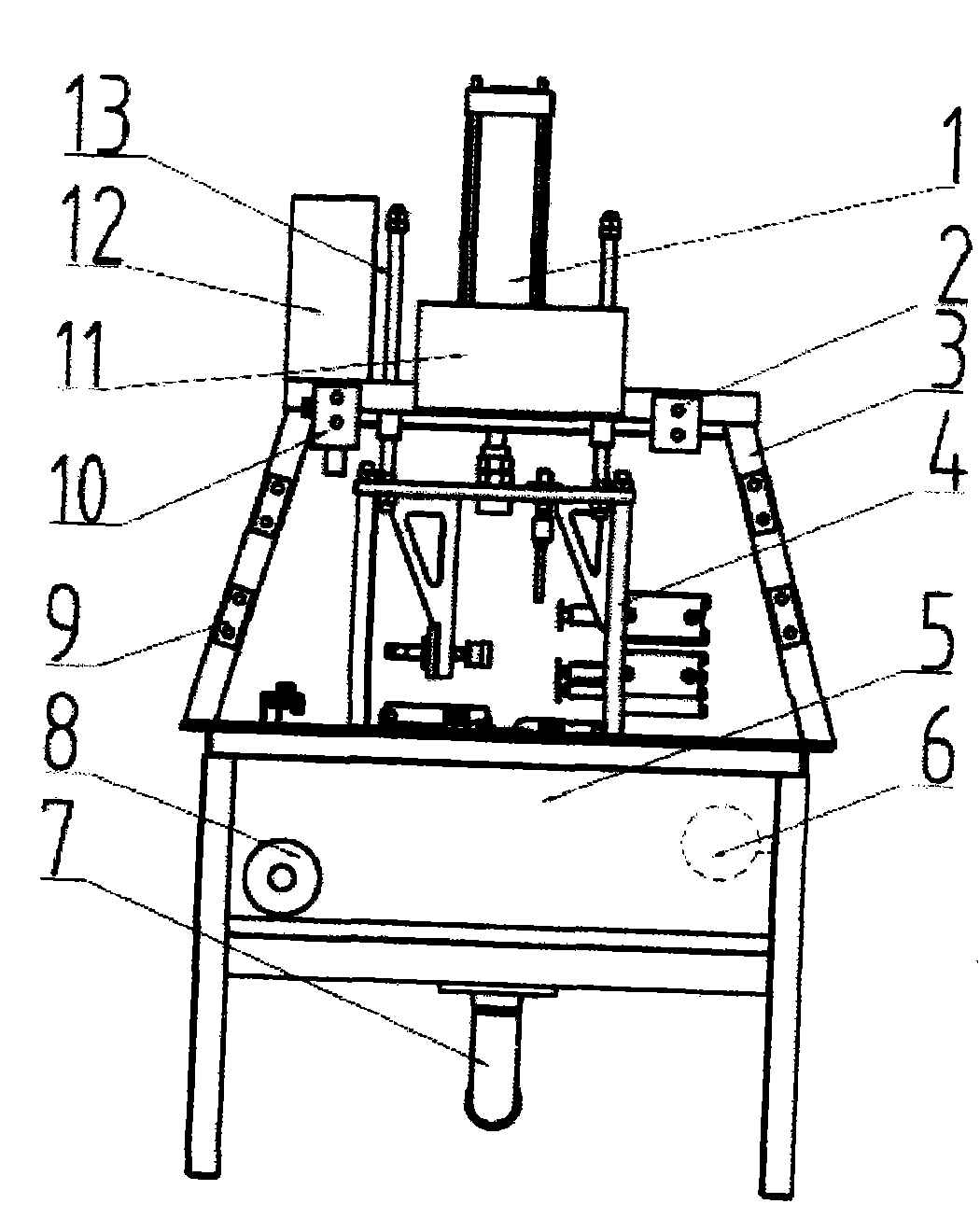

[0011] Such as figure 1 , figure 2 shown. The present invention consists of a frame 3, a leak detection tool 4 and a water tank 5. The frame 3 is a cone structure. Frame 3 is connected with external air source and power supply, and the top of frame 3 is provided with power supply control box 12, lifting cylinder 1 and guide rod 13. The side end of the frame 3 is provided with an air source treatment triplex 10, a pressure reducing valve 2, a control valve 9 and a connecting air pipe. The top plate 18 of the airtightness detection tool 4 is provided with a connection hole that cooperates with the lifting cylinder 1 and the guide rod 12 at the top of the frame 3. The shape and relative position of the connection hole are determined in the initial design, and it has versatility. The top plate 18 and the bottom plate 16 is connected as a whole by connecting rod 17. The frame 3 is connected with the replaceable special sealing test tool 4 through the lifting cylinder 1 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com