Glass passivation pellet (GPP) chip electrophoresis fluid

A glass passivation, electrophoretic liquid technology, applied in electrophoretic coatings and other directions, to achieve the effect of small IR at room temperature, good density and firmness, and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The formula of the electrophoretic liquid of the present invention is: it is made up of following components: volume percentage is 93.75% isopropanol, volume percentage is the acidic surfactant of 6.25%; Add 375g glass powder in every 10000ml above-mentioned mixed liquid.

[0013] The technical effect of the electrophoretic solution of the present invention will be described below in conjunction with the accompanying drawings.

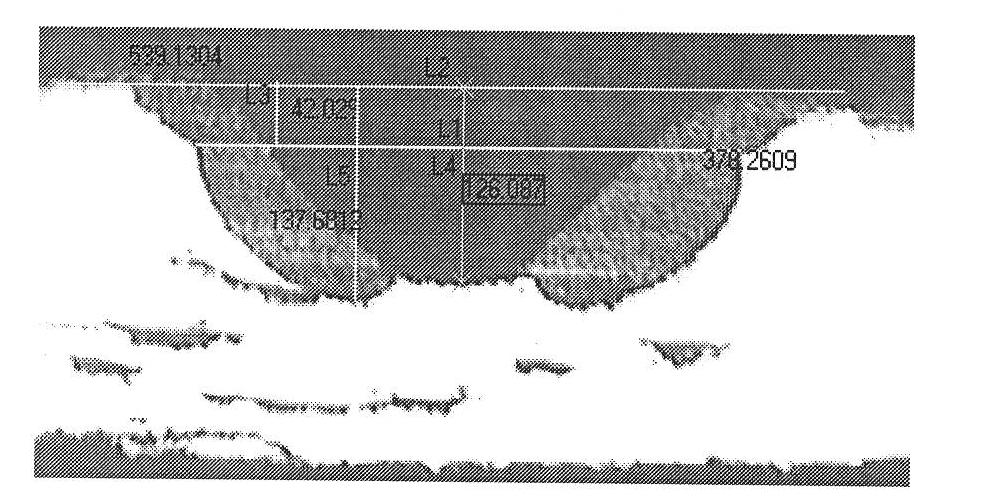

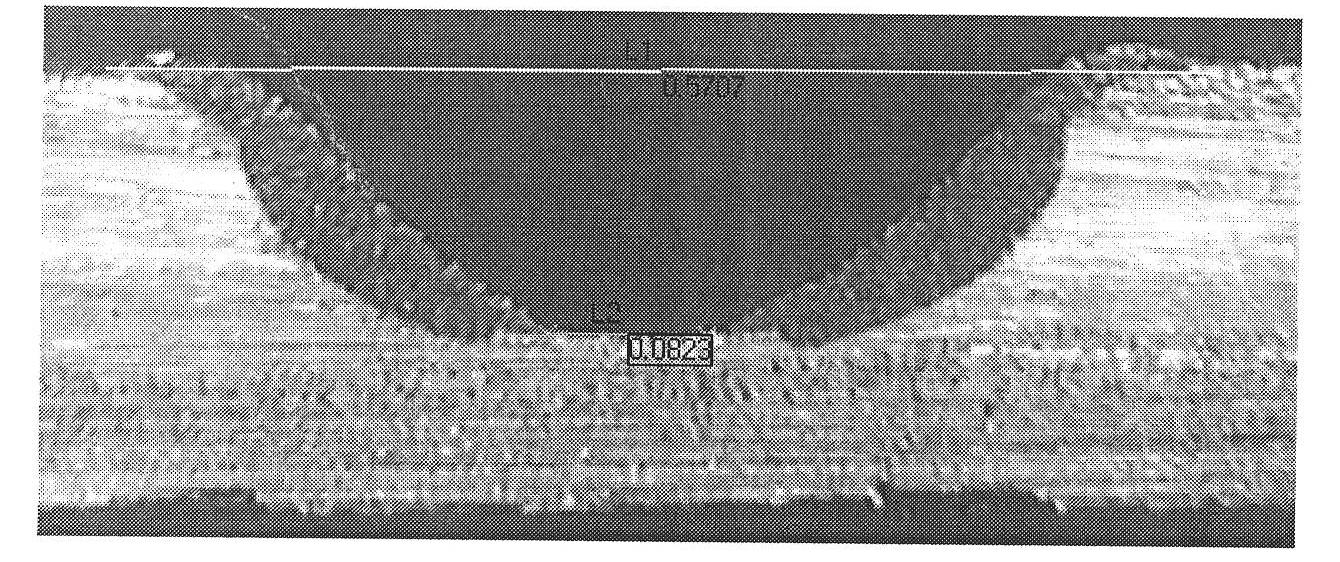

[0014] 1. Improved uniformity of glass shape

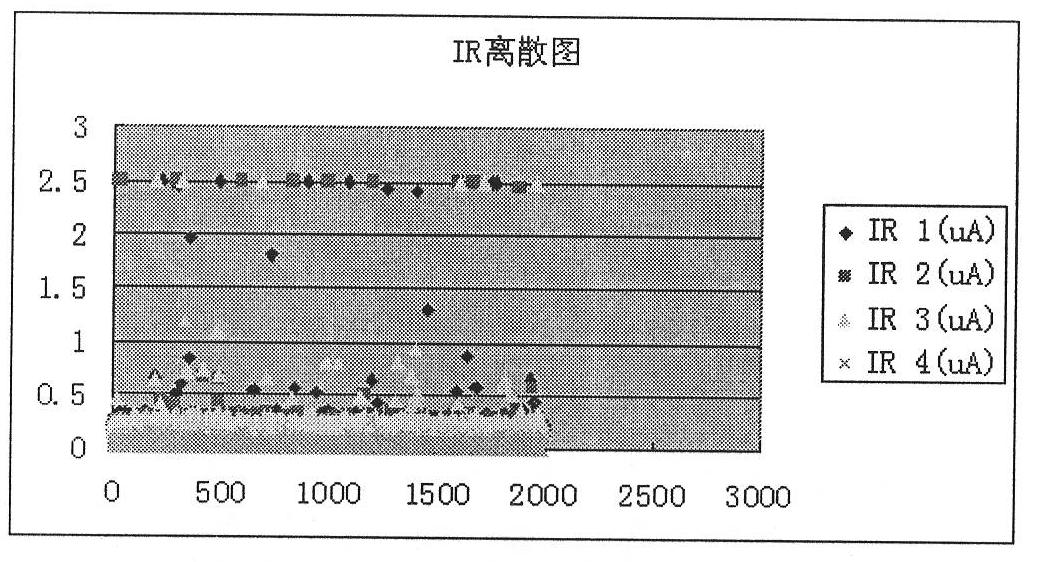

[0015] Such as figure 1 and 2 As shown, the traditional electrophoresis formula has the following defects: First, the orientation is not good, that is, during the electrophoresis process, glass will be applied to the parts of the chip that do not need glass protection, resulting in deglazing of the parts that do not need glass after the glass is sintered. ; Utilize the electrophoretic fluid of the present invention, completely eliminate the existence of this problem. It can not only ensure the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com