Method for arranging multiple escapes on building envelope opening and escape device

An escape device and enclosure structure technology, which is applied in the field of escape exits, can solve problems such as difficulty in manual operation, easy loss of escape hammer, and injury to escape personnel, etc., and achieves the effect of simple device principle, wide range of use, and reduced accident losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

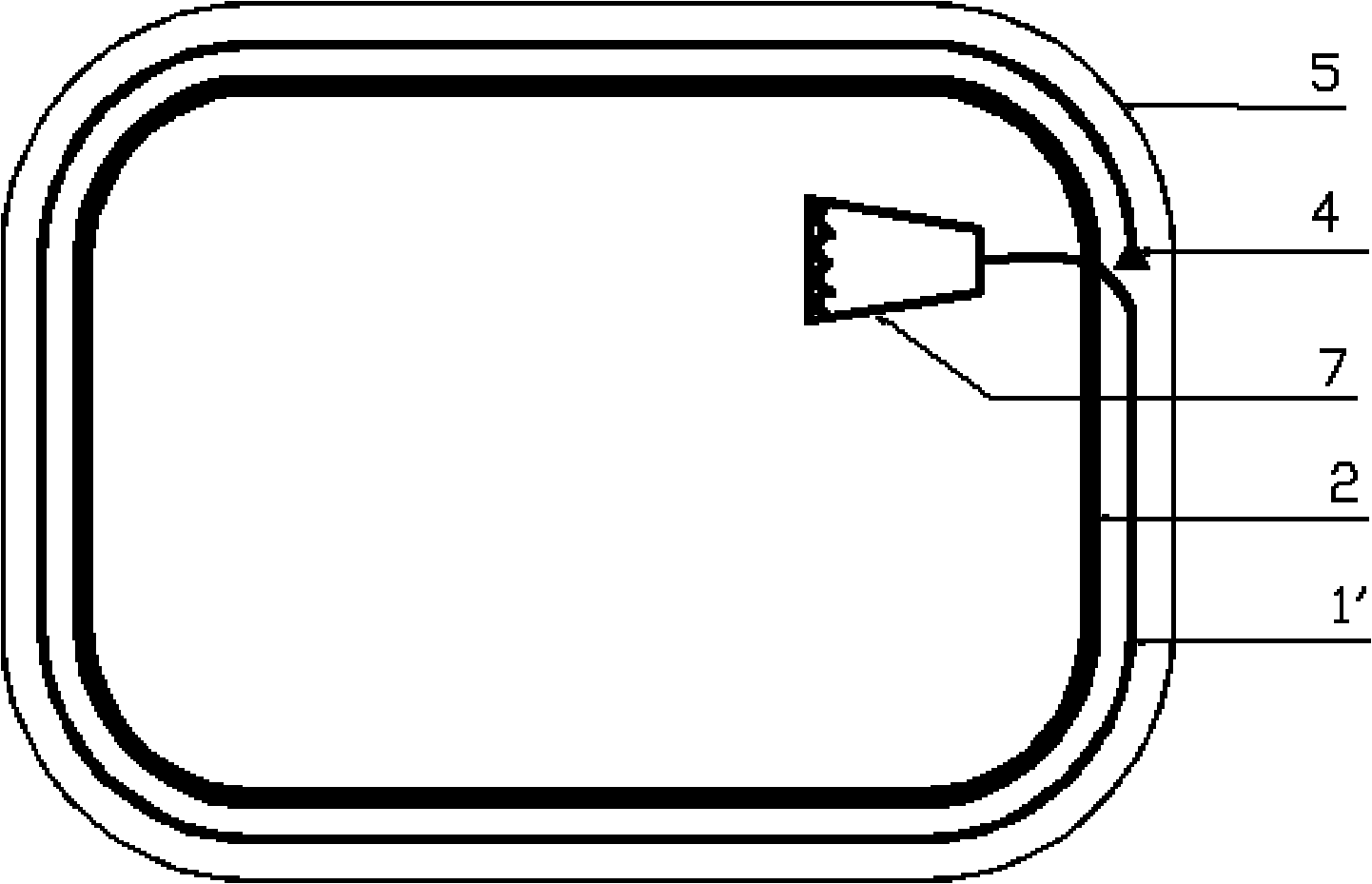

[0028]According to the method of setting multiple escape openings proposed by the present invention, the present invention provides two kinds of cutting escape devices and one sealing strip escape device, which are respectively used in the pasting and sealing strip fixing methods. Hereinafter, specific implementation methods are introduced by taking automobile and train glass as examples, and the application of the glass curtain wall to the method and device is similar to this.

[0029] first escape device

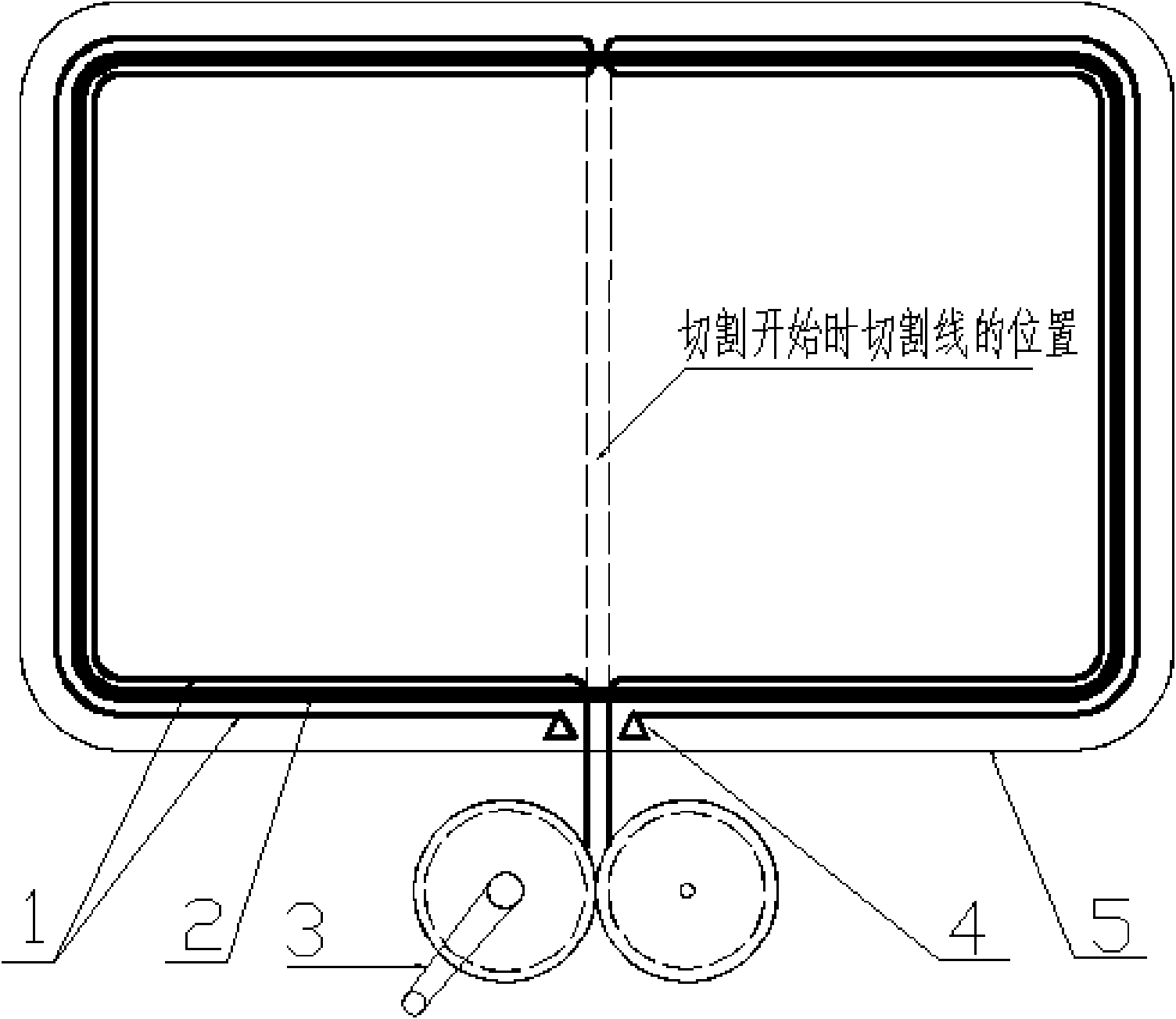

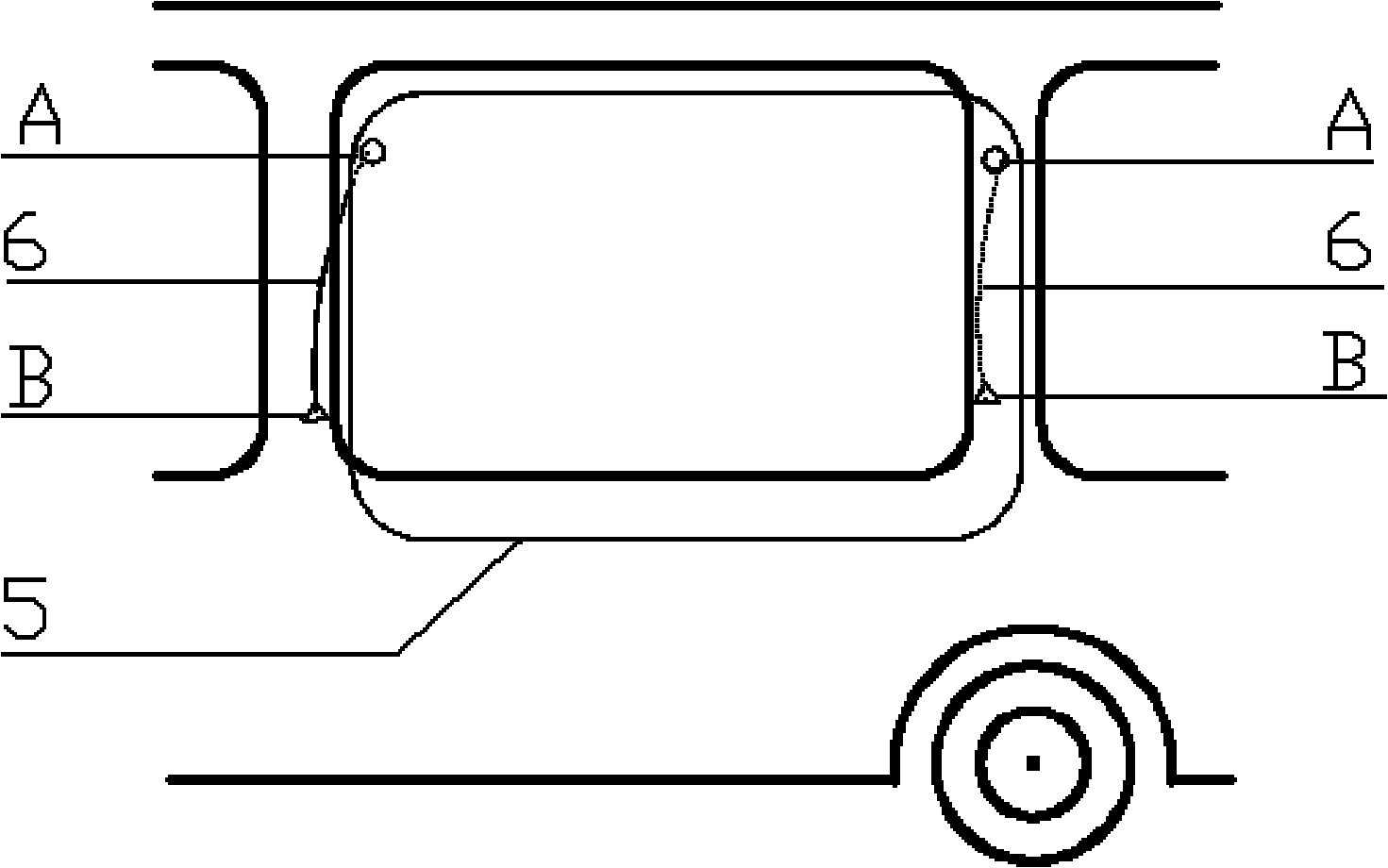

[0030] Figure 1A In order to use the escape device of the rocker-type wire-retracting mechanism, the cutting line 1 surrounds both sides of the glue 2 in this device, and the wire-retracting mechanism connects the cutting line from the inside of the glue; as shown in the figure, when the cutting starts, the cutting line 1 is first located on the dotted line position, along with the pulling of the pulling wire mechanism to the cutting line 1, the glue 2 is cut from the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com