Skinned jumper wire shaping mill

A molding machine, jumper technology, applied in the direction of circuit/collector parts, electrical components, circuits, etc., can solve the problems of insulator and conductor parts are not tightly combined, can not meet the needs of use, etc., to achieve high production efficiency, line The effect of wide path and action science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

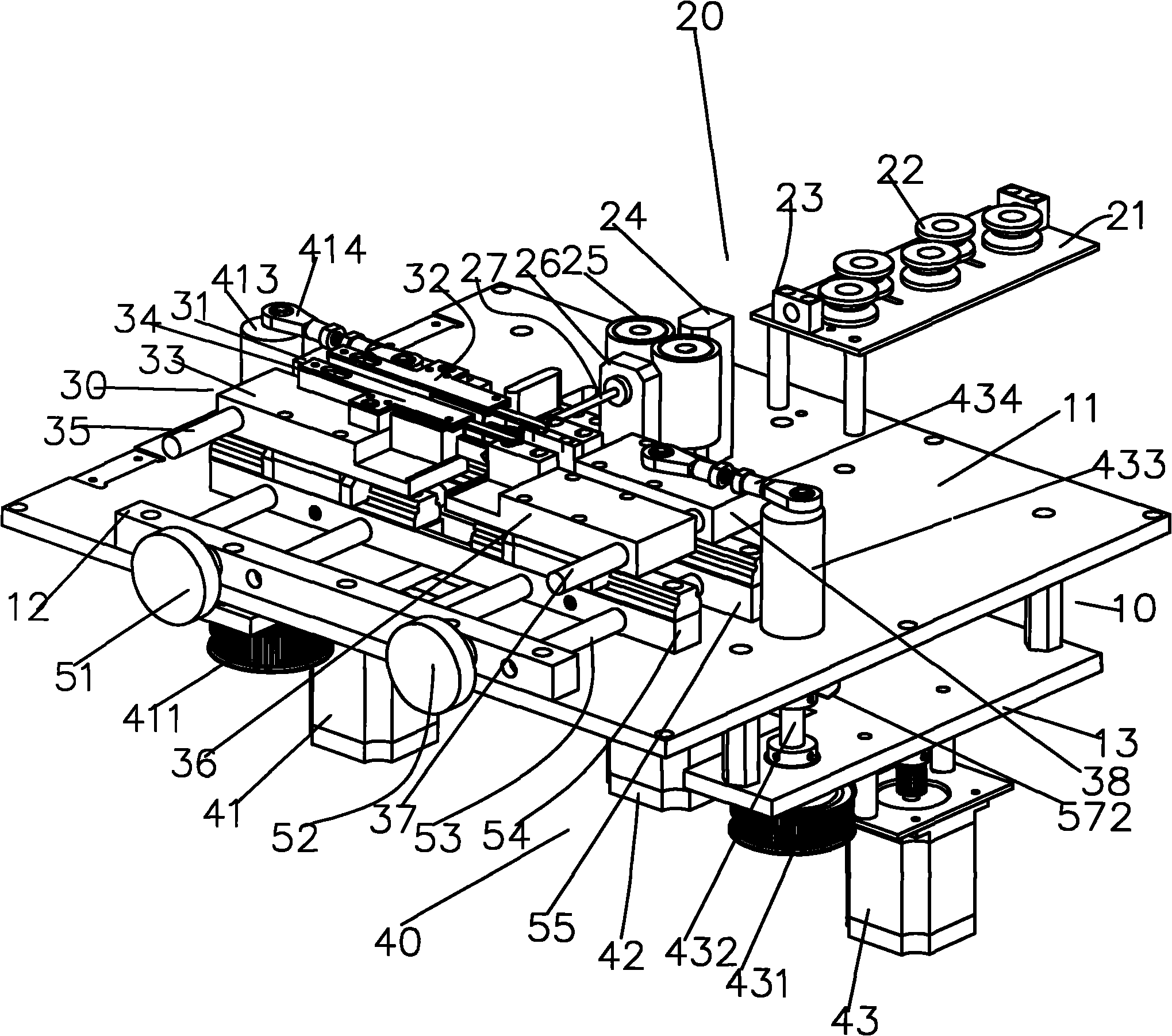

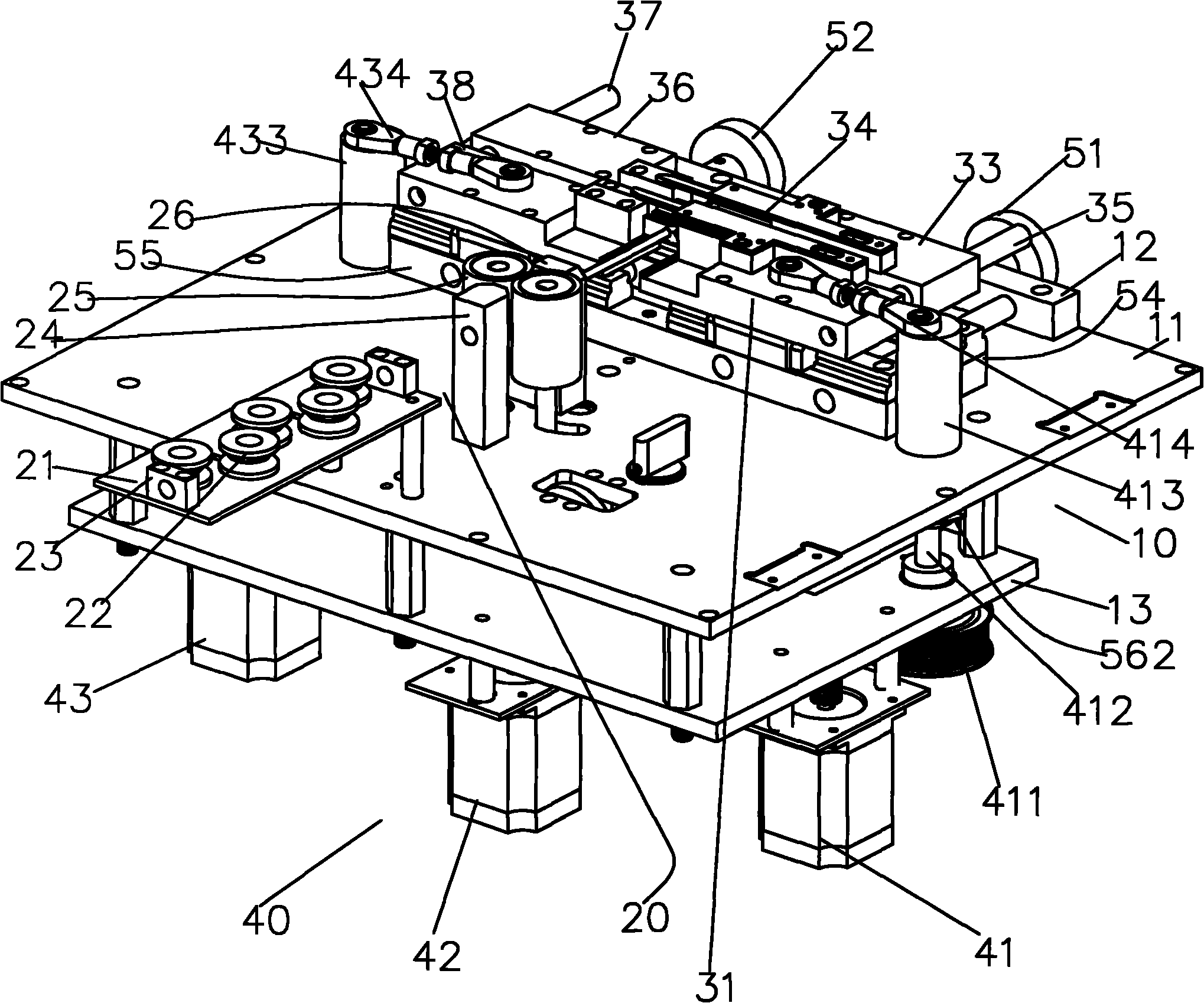

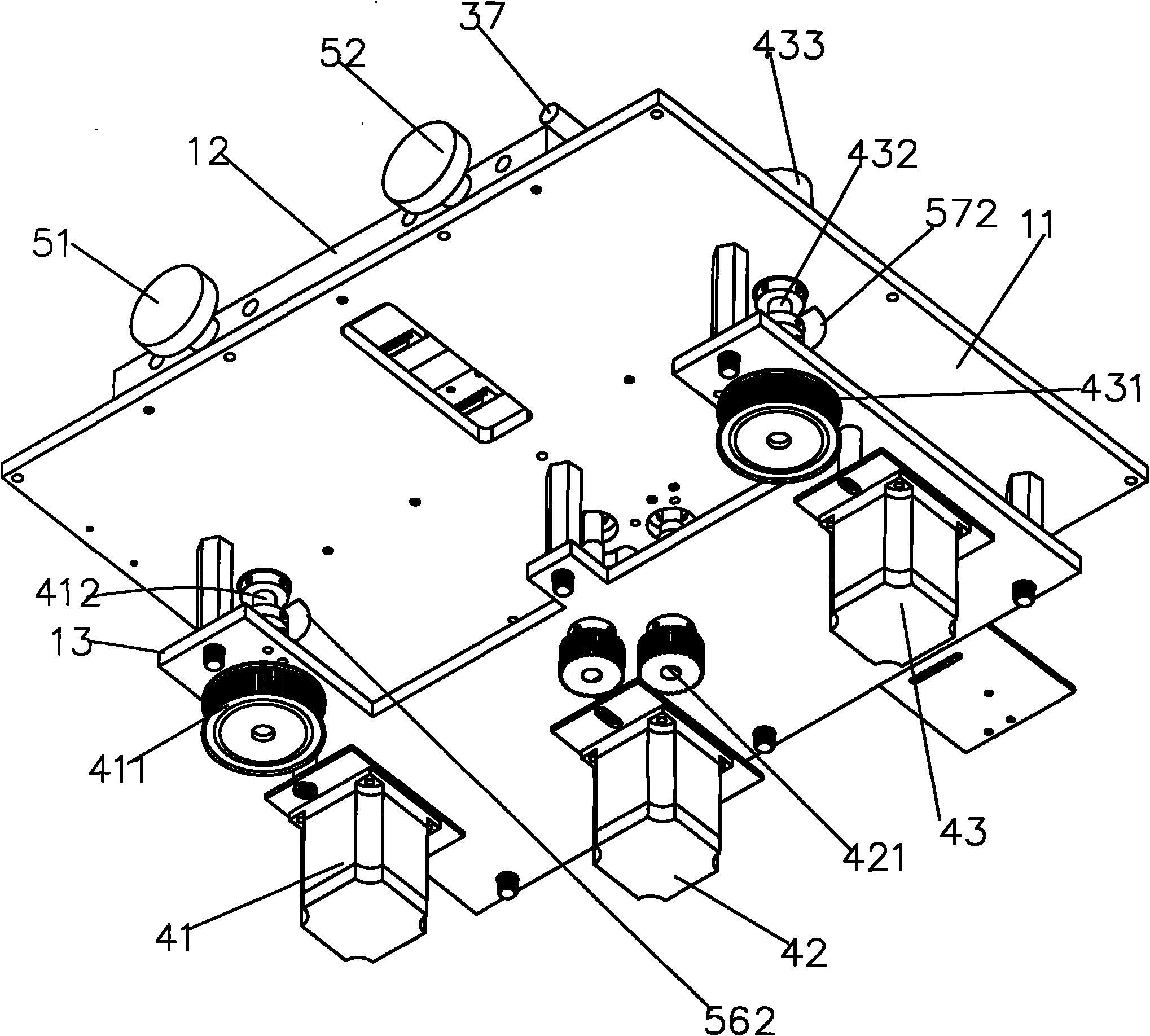

[0030] refer to Figure 1-11 , a peeling wire jumper forming machine includes a frame 10, a wire feeding device 20, a peeling forming device 30, a driving device 40 and a control component, and the frame is used for fixedly installing the wire feeding device 20, the peeling forming device 30, the driving device 40 and The control part, the wire feeding device 20 is used to send the wire rod 80 to be processed to the peeling forming device 30, and the peeling forming device 30 is used to peel off part of the insulation of the wire rod 80 sent and cut and extrude it, and the driving device 40 is used In driving the wire feeding device 20 and the peeling and forming device 30 , the control unit 40 is used to control the wire feeding device 20 , the peeling and forming device 30 and the driving device 40 .

[0031] The frame 10 includes a working panel 11 and a fixing plate 13 fixed below it in parallel, and a fixing bar 12 is provided at the edge of one side of the upper surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com