Preparation method, product and application of electrolyte for high voltage aluminum electrolytic capacitor

An aluminum electrolytic capacitor and electrolyte technology, applied in the field of electrolyte, can solve the problems of high frequency of capacitors, short storage life, large leakage current of capacitors, etc., to improve safety performance and service life, simple operation, high performance, etc. The effect of flash voltage

Inactive Publication Date: 2011-05-25

东莞宏强电子有限公司

View PDF5 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] The purpose of the present invention is to provide an electrolyte solution for high-voltage aluminum electrolytic capacitors, so as to solve the problem that the current electrolyte solution is difficult to meet the requirements of high frequency, low impedance, low leakage and long life of the capacitor, especially when the ammonium borate electrolyte electrolyte is used. , it can produce esterification reaction with ethylene glycol to generate water, and the technical problems such as large leakage current of the capacitor and short storage life due to hydration

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

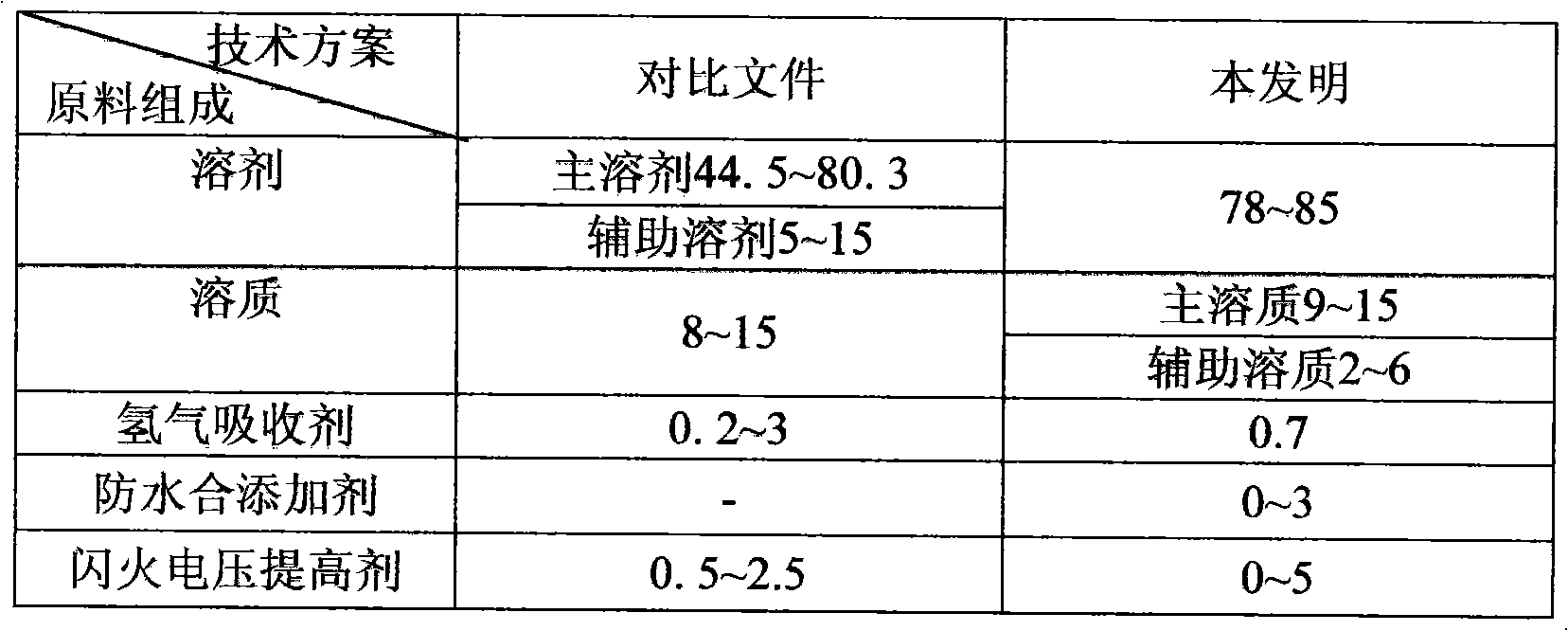

Login to View More Abstract

The invention provides a preparation method of an electrolyte for a high voltage aluminum electrolytic capacitor and the electrolyte obtained by the preparation method. The electrolyte comprises the following components by weight portion: 78-85 main solvent, 0.7 hydrogen absorber, 9-15 main solute, 0.3 waterproof combined additive, 2-6 auxiliary solute and 0-3 sparking voltage improving agent. The invention comprises the key technology that: high-molecular-weight aliphatic dicarboxylic acid with branched-chain alkyl is used as a main electrolyte, and an aromatic nitro compound cathode depolarizing agent is added, and an ammonium phosphorous acid is added to prevent an alumina membrane from hydration. The electrolyte provided by the invention can withstand more than 3,000 hours under the loads that the sparking voltage is greater than 470V and the temperature is 125 DEG C, has the advantages of high sparking voltage, high conductivity and high reliability, and can be applied to the manufacture of the high voltage electrolytic capacitor.

Description

Technical field [0001] The present invention involves the field of electrolyte technology, which specializes in an electrolyte and it is used to prepare high -voltage aluminum electrolytic capacitors for a high -voltage aluminum electrolytic capacitor. Background technique [0002] Aluminum electrolytic capacitors are one of the basic components of electronic products.With the continuous improvement of the quality of electronic products and the expansion of the application range of aluminum electrolytic containers, higher requirements are put forward.Electronic products such as switching power supply and energy -saving lamps have high safety performance of high -voltage electrolytic capacitors.In the filter circuit, the capacitor is under high voltage and high -ripple current. If the feedback is unstable or applies overvoltage, it can cause accidents such as damage, fire, and combustion of the electrical container.Aluminum electrolytic capacitor electrolyte is the actual cathode ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01G9/00H01G9/035

Inventor 汪衍石木果

Owner 东莞宏强电子有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com