Device for fixing heating surface in supercritical tower type boiler

A technology for fixing devices and heating surfaces, applied in the direction of boiler support/positioning devices, etc., can solve problems such as small expansion, uneven heating, no cooling of pipe clamps and corner plates, etc., to achieve effective expansion, large expansion, and heat uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

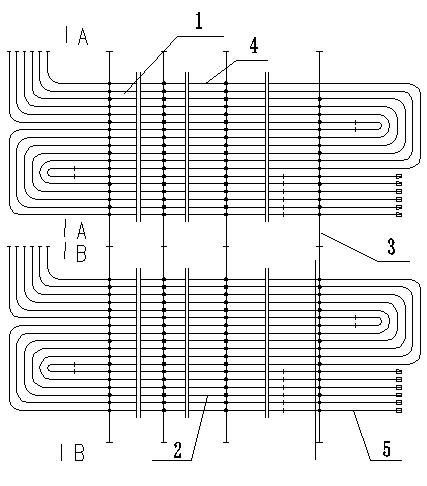

[0018] A heating surface fixing device in a supercritical tower boiler, the composition of which includes: the heating surface is arranged in a tower type and fixed above the furnace; Horizontally arranged, the hanging of the heating surface adopts the hanging tube 3 from top to bottom to hang and fix in sequence, all the heating surfaces pass through the front water cooling wall or the rear water cooling wall, and the heating surface tube and the water cooling wall fin pass through the water cooling wall The other end is free to expand. The hanging device 1 on the heating surface in the low-temperature flue gas area has a set of upper serpentine tubes 4 arranged in sequence. The hanging device 1 on the heating surface in the high-temperature flue gas area 2 has a group of lower serpentine pipes 5 arranged in sequence.

Embodiment 2

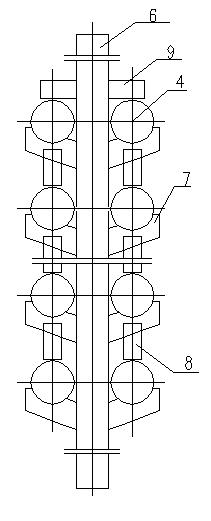

[0020] The heating surface fixing device in the supercritical tower boiler described in Example 1, the hanging device of the heating surface in the low-temperature flue gas area adopts a barb steel plate pressure plate hanging device, including the upper hanging pipe 6, the The upper hanging pipe 6 is connected to the upper hanging plate 7, the upper hanging plate 7 is connected to the lower pressing plate 8, and the upper hanging pipe 6 is connected to the upper pressing plate 9, between the upper hanging hanging plate and the lower pressing plate Upper serpentine tube 4 is housed.

Embodiment 3

[0022] The heating surface fixing device in the supercritical tower boiler described in Example 1 or 2, the hanging device of the heating surface in the high-temperature flue gas area adopts steel plate openings to pass through the heating surface tube, and two hanging Hanging pipe hangs a row of heating surfaces, so that both sides of the hanging plate are cooled. Its structure includes lower hanging pipes 10 on both sides. Hanging plate 11 is equipped with lower serpentine pipe 5.

[0023] The length of the horizontal heating surface of the tower arrangement is greater than 20 meters.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com