Downward gas drainage drill hole and pressure testing drill hole sealing method

A gas drainage and pressure measurement technology, which is used in gas drainage, measurement, earthwork drilling, etc., can solve problems such as unsatisfactory sealing effect of gas drainage holes and pressure measurement holes, and inability to accurately test coal seam gas pressure, etc. Wide practicability, less difficulty in operation, and high ergonomics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

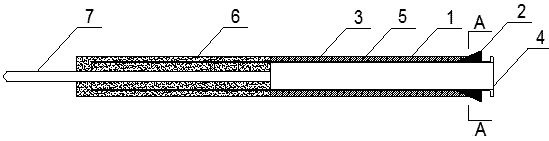

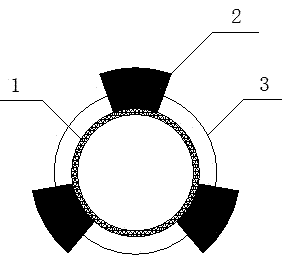

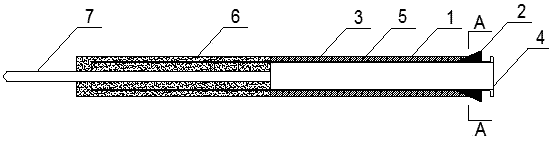

[0017] like figure 1 As shown, the downhole gas drainage drilling and pressure measurement drilling sealing method of the present invention: first use the existing conventional downhole drilling construction method, and construct a downhole 3 with a diameter of 90 mm to 200 mm from the roadway to the coal seam below. , stop drilling when the downhole 3 is drilled to a position about 1m away from the coal seam roof, and withdraw the drill pipe; then install the steel casing 1 in the downhole 3, and the connection of the steel casing 1 needs to be wrapped with raw material tape, etc. sealing material to ensure that the steel casing 1 is airtight; the length of the steel casing 1 entering the downhole 3 is based on the distance between the front end of the steel casing 1 and the bottom of the downhole 3 about 1 m, and A flange 4 is installed at the end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com