Novel drilling pile casting and manufacturing method thereof

A manufacturing method and technology of bored piles, which are applied in sheet pile walls, buildings, and foundation structure engineering, etc., can solve problems such as difficulty in ensuring the hole formation rate of bored piles, difficulty in ensuring construction quality, and low construction efficiency, so as to improve the cost Hole quality and construction progress, saving manpower and materials, shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

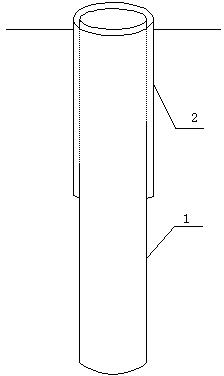

[0016] A new type of bored pile protective tube, which consists of: a set of inner small protective tube 2, the inner small protective tube section and section are welded together, and the outer side of the inner small protective tube A set of large outer protective cylinders 3 are arranged concentrically, and a fixed slurry 1 is filled between the small inner protective cylinder and the large outer protective cylinder.

Embodiment 2

[0018] A new type of manufacturing method of bored pile protection tube,

[0019] Prefabricated components: In the first step, a steel plate with a thickness of 10mm is selected, and the steel plate is rolled into a small inner protective tube with a diameter of 30cm larger than the designed pile hole; the second step is a steel plate with a thickness of 10mm, and the steel plate is rolled into a diameter larger than the design A large outer protective tube with a pile hole diameter of 40cm.

[0020] Pre-dug a hole in the ground with a diameter that matches the outer protective tube, use a drill to drill the hole, put the manufactured outer protective tube into the dug pit, and place a group of outer protective tube from top to bottom Down, follow the drilling rig down into the converted hole, and weld between each section with a welding machine. When the hole is drilled through the frozen soil layer, run down a set of small inner protective cylinders, and when each section of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com