Process for quickly breaking cell walls of Chinese wolfberry seeds and extracting seed oil

A kind of Lycium barbarum seeds and extraction technology, applied in the direction of fat oil/fat production, fat production, etc., can solve the problems of reduction, large molecular weight, etc., and achieve the effects of reduced extraction time, low extraction temperature, and less industrial consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

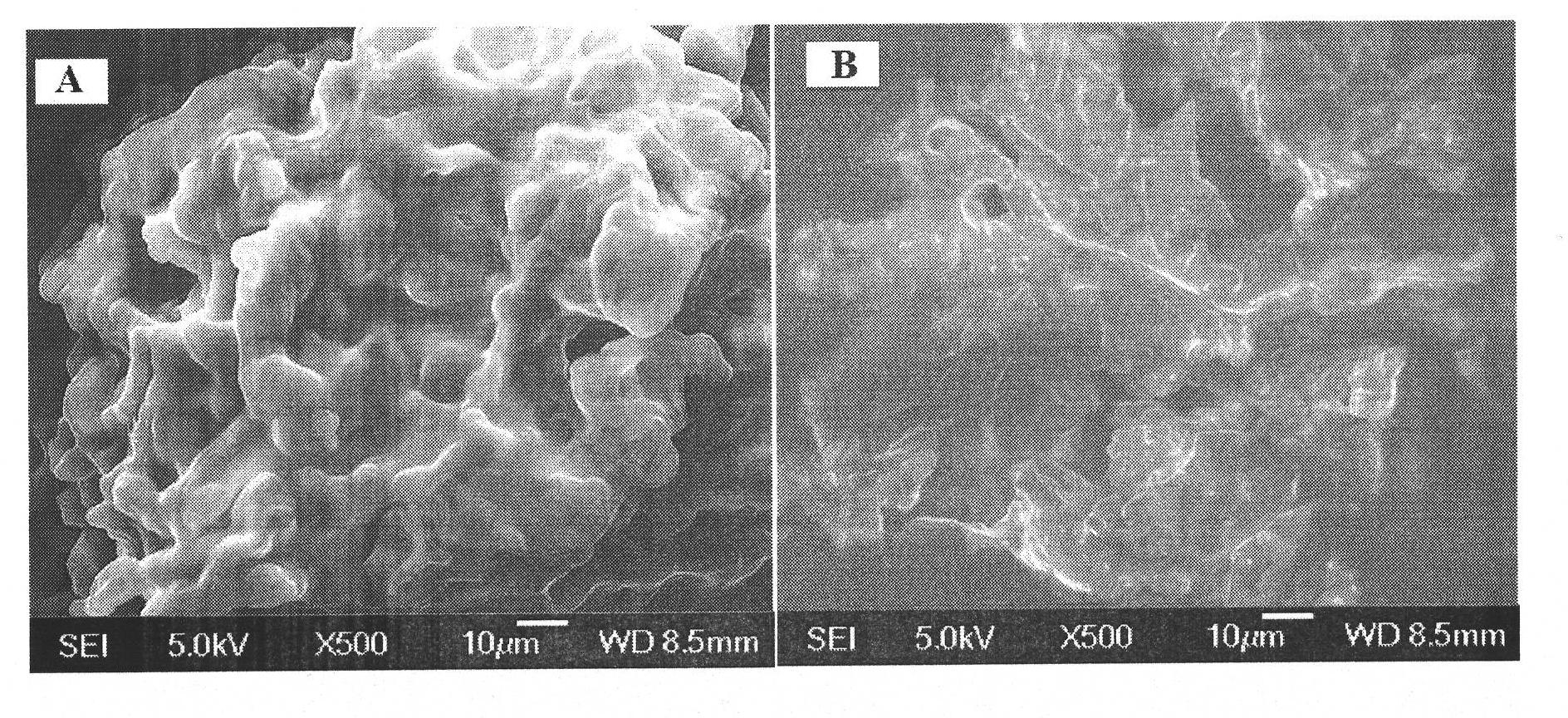

Image

Examples

Embodiment 1

[0023] Embodiment 1 Lycium barbarum seed cell rapid wall breaking and seed oil extraction process comprise the following steps:

[0024] (1) Lycium barbarum seed cell wall breaking treatment: After the washed and dried wolfberry seeds are crushed to a particle size of 20 mesh, they are placed in the extraction kettle; CO is introduced into the extraction kettle. 2 , after raising the pressure in the extraction kettle to 40 MPa at normal temperature, keep it for 15 minutes; then close the inlet valves at both ends of the extraction kettle, and drop the pressure in the extraction kettle to atmospheric pressure within 1 minute to obtain the broken wolfberry seeds.

[0025] (2) pack the Lycium barbarum seeds after the broken wall of step (1) gained in the extraction kettle, pass into CO simultaneously 2 , the extraction kettle pressure is 28.5Mpa, temperature is 40.2 ℃, the consumption of entrainer ethanol (mass concentration is 95%) adds 6.88mL, CO 2 The flow rate is 50L / h under...

Embodiment 2

[0027] Embodiment 2 Lycium barbarum seed cell rapid wall breaking and seed oil extraction process comprise the following steps:

[0028] (1) Lycium barbarum seed cell wall breaking treatment: After the washed and dried wolfberry seeds are crushed to a particle size of 60 mesh, they are placed in the extraction kettle; CO is introduced into the extraction kettle. 2 After raising the pressure in the extraction kettle to 45 MPa at normal temperature, keep it for 10 minutes; then close the inlet valves at both ends of the extraction kettle, and drop the pressure in the extraction kettle to atmospheric pressure within 5 minutes to obtain the wolfberry seeds after the wall is broken.

[0029] (2) pack the Lycium barbarum seeds after the broken wall of step (1) gained in the extraction kettle, pass into CO simultaneously 2 , the extraction kettle pressure is 30.0Mpa, temperature is 45.0 ℃, the consumption of entrainer ethanol (mass concentration is 95%) adds 8.45mL, CO 2 The flow ra...

Embodiment 3

[0031] Embodiment 3 Lycium barbarum seed cell rapid wall breaking and seed oil extraction process comprise the following steps:

[0032] (1) Lycium barbarum seed cell wall breaking treatment: After the washed and dried wolfberry seeds are crushed to a particle size of 40 mesh, they are placed in the extraction kettle; CO is introduced into the extraction kettle. 2 After raising the pressure in the extraction kettle to 43 MPa at normal temperature, keep it for 12 minutes; then close the inlet valves at both ends of the extraction kettle, and drop the pressure in the extraction kettle to atmospheric pressure within 3 minutes to obtain the broken wall wolfberry seeds.

[0033] (2) pack the Lycium barbarum seeds after the broken wall of step (1) gained in the extraction kettle, pass into CO simultaneously 2 , the extraction kettle pressure is 29.0Mpa, temperature is 42.0 ℃, the consumption of entrainer ethanol (mass concentration is 95%) adds 7.50mL, CO 2 The flow rate is 35L / h u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com