Blend of carbon dioxide-propylene oxide copolymers and preparation method thereof

A technology of propylene oxide and carbon dioxide, which is applied to the blend of carbon dioxide-propylene oxide copolymer and its preparation field, can solve the problems of limiting the application range of PPC, low elongation at break and the like, and achieves high elongation at break, Improves compatibility and suppresses precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

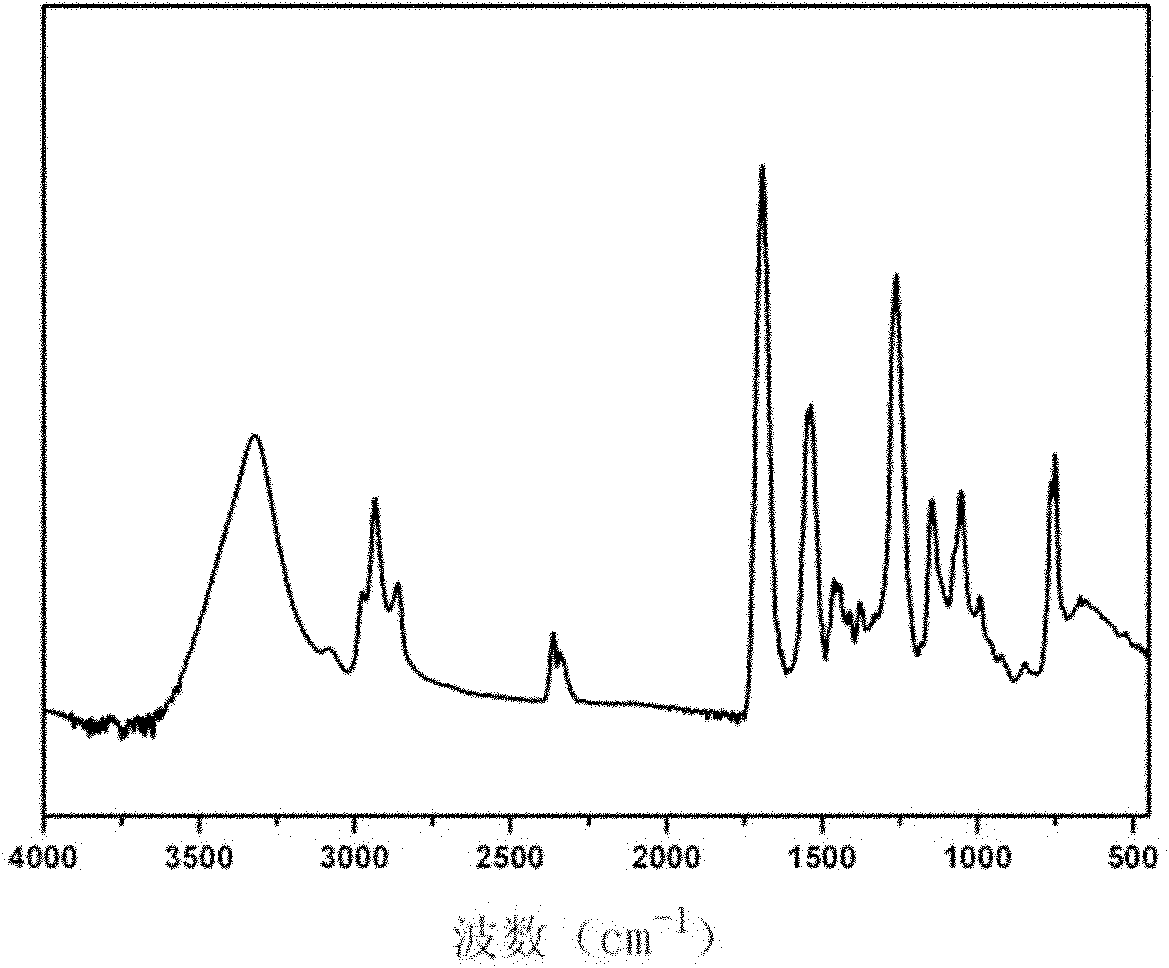

Image

Examples

preparation example Construction

[0049] The present invention also provides a method for preparing a blend of carbon dioxide-propylene oxide copolymer, comprising: a), preparing urethane compounds;

[0050] b), mixing the urethane compound prepared in step a) with the carbon dioxide-propylene oxide copolymer in a weight ratio of 5 to 15: 85 to 95 to obtain a solid mixture;

[0051] c), the solid mixture obtained in step b) is subjected to a melt blending operation to obtain a blend of carbon dioxide-propylene oxide copolymer;

[0052] The urethane compound is one of the compounds represented by formulas I to VI. Wherein, n is 2, 4, 6, 10 respectively; R is methyl, ethyl, propyl or butyl.

[0053] According to the present invention, the urethane compounds are prepared using a non-isocyanate method, that is, diisocyanates are not used to prepare the urethane compounds, but aliphatic dibasic primary amines and carbonates are used to prepare the urethane compounds. The carbonate used in the present invention is...

Embodiment 1

[0062] The 500mL round bottom flask was vacuumized 4 times to make its vacuum degree 669Pa, and nitrogen was charged into the round bottom flask, and the nitrogen volume content was 99.99%. 11.6g (0.1mol) of hexamethylenediamine and 25mL (0.28mol) of propylene carbonate and CaH 2 Refluxed 45 mL of anhydrous dichloromethane was added to the round bottom flask. Put the round-bottomed flask into a constant temperature control bath, control the temperature at 30±5°C, and continuously stir the mixed solution in the round-bottomed flask at a speed of 90rpm for 12h, so that the cyclic carbonate and hexamethylenediamine undergo ring-opening addition reaction, After the reaction, add 240mL of analytically pure anhydrous ethyl acetate to the mixed solution, stir the resulting mixed solution for 3h at a speed of 120rpm, the white solid powdery product slowly settles out, and separate the white powder product, each time with 60g of analytically pure Wash with anhydrous ethyl acetate and ...

Embodiment 2

[0067] The 500mL round bottom flask was vacuumized 4 times to make its vacuum degree 669Pa, and nitrogen was charged into the round bottom flask, and the nitrogen volume content was 99.99%. 18.2g (0.16mol) hexamethylenediamine and 33.1g (0.38mol) ethylene carbonate and through CaH 2 Refluxed 60 mL of anhydrous dichloromethane was added to the round bottom flask. Put the round-bottomed flask into a constant temperature control bath, control the temperature at 30±5°C, and continuously stir the mixed solution in the round-bottomed flask at a speed of 100rpm for 10h, so that the cyclic carbonate and hexamethylenediamine undergo ring-opening addition reaction, After the reaction is over, add 300mL of analytically pure anhydrous ethyl acetate to the mixed solution, stir the resulting mixed solution for 3h at a speed of 120rpm, the white solid powdery product slowly settles out, separates the white powdery product, and the white solid powdery product slowly After precipitation, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com