Polyester composite filled with lignin and preparation method thereof

A composite material and lignin technology, which is applied in the field of lignin-filled polyester composite materials and its preparation, can solve the problems of lignin application, etc., and achieve the effect of reducing production costs and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

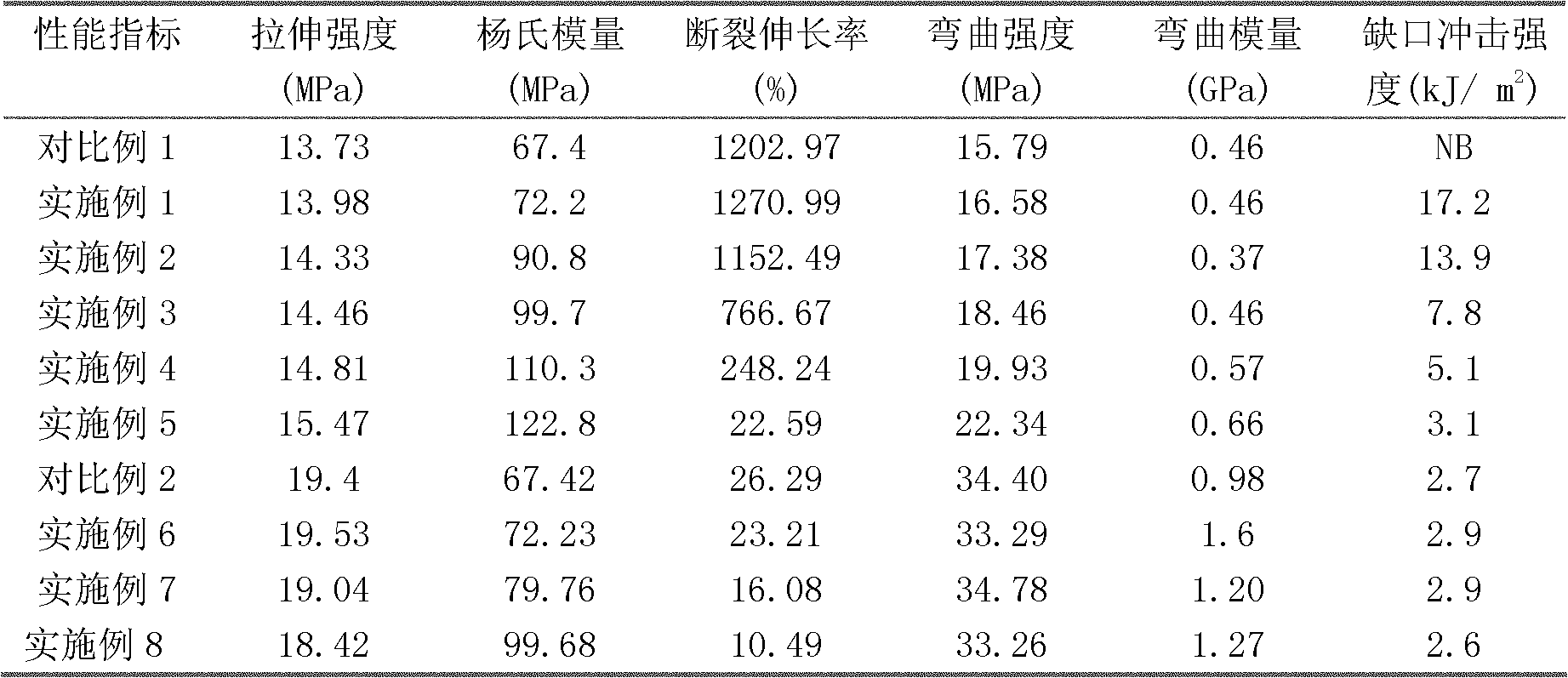

Examples

Embodiment 1

[0028] The premixed mixture containing 95% (wt%) polycaprolactone (80,000 weight-average molecular weight) and 5% (wt%) cellulose enzymatic lignin was added to the twin-screw machine, and melt blended , extruded and granulated into a composite material, and injected into a test sample for performance testing.

[0029] The set temperature and processing conditions of each zone of the screw are: the temperatures in zones 1 to 7 are 120°C, 130°C, 135°C, 140°C, 145°C, 145°C, 135°C, and the head temperature is 135°C, stay for 3 to 5 minutes , the pressure is 12MPa, and the feeding speed is 198rpm.

Embodiment 2

[0031] The premixed mixture containing 90% (wt%) polycaprolactone (weight average molecular weight 80,000) and 10% (wt%) cellulose enzymatic lignin is added to the twin-screw machine, and melt blended , extruded and granulated into a composite material, and injected into a test sample for performance testing.

[0032] The set temperature and processing conditions of each zone of the screw are: the temperatures in zones 1 to 7 are 120°C, 130°C, 135°C, 140°C, 145°C, 145°C, 135°C, and the head temperature is 135°C, stay for 3 to 5 minutes , the pressure is 12MPa, and the feeding speed is 198rpm.

Embodiment 3

[0034] The premixed mixture containing 80% (wt%) polycaprolactone (weight average molecular weight 80,000) and 20% (wt%) cellulose enzymatic lignin is added to the twin-screw machine, and melt blended , extruded and granulated into a composite material, and injected into a test sample for performance testing.

[0035] The set temperature and processing conditions of each zone of the screw are: the temperatures in zones 1 to 7 are 120°C, 130°C, 135°C, 140°C, 145°C, 145°C, 135°C, and the head temperature is 135°C, stay for 3 to 5 minutes , the pressure is 12MPa, and the feeding speed is 198rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com