Method for producing polyaluminium chloride

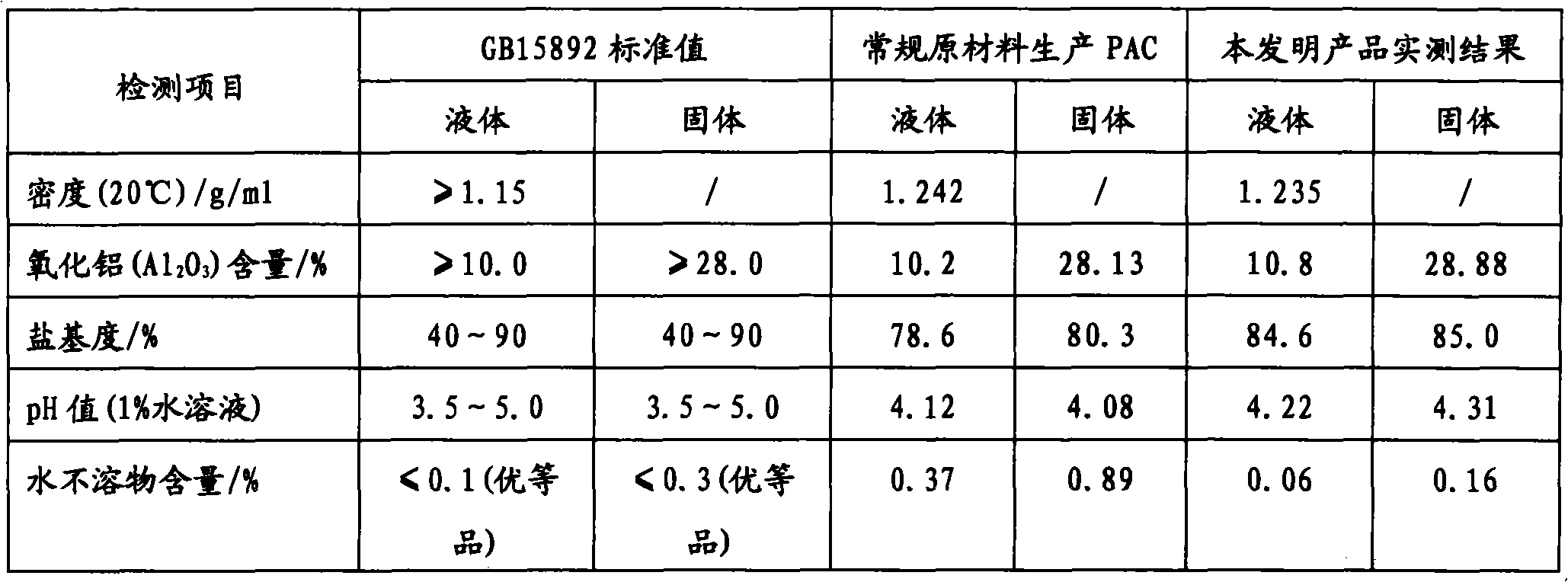

A polyaluminum chloride, production method technology, applied in aluminum chloride, aluminum halide, flocculation/sedimentation water/sewage treatment and other directions, can solve the problems of low salinity, high water-insoluble content, high manufacturing cost, and achieve Wide application range, low water-insoluble content, and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] A kind of production method of polyaluminum chloride of the present invention, comprises the steps:

[0018] In an acid-resistant, steam-heated reaction vessel with a stirring device, start stirring, add water and hydrochloric acid, prepare a hydrochloric acid solution with a volume concentration of 22%, raise the temperature to 65°C under normal pressure, and start adding aluminum-containing waste residue. Raise the temperature, after the aluminum-containing waste residue is added, the temperature of the feed liquid system is controlled at 95°C, and the reaction is carried out under normal pressure for 4 hours; the feed liquid after the reaction is filtered to remove waste residue impurities, and the mother liquor is taken into the acid-proof, steam Heat the reaction vessel, start stirring, add an appropriate amount of water, and start adding calcium aluminate powder. After feeding, adjust the density of the feed liquid to ≥ 1.20g / ml with water, and then add synergist. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com