Crane jib special for forklift

A technology for forklifts and booms, applied in the direction of lifting devices, etc., can solve the problems of falling off the base of the bracket, large front and rear width of the bracket, and heavy weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

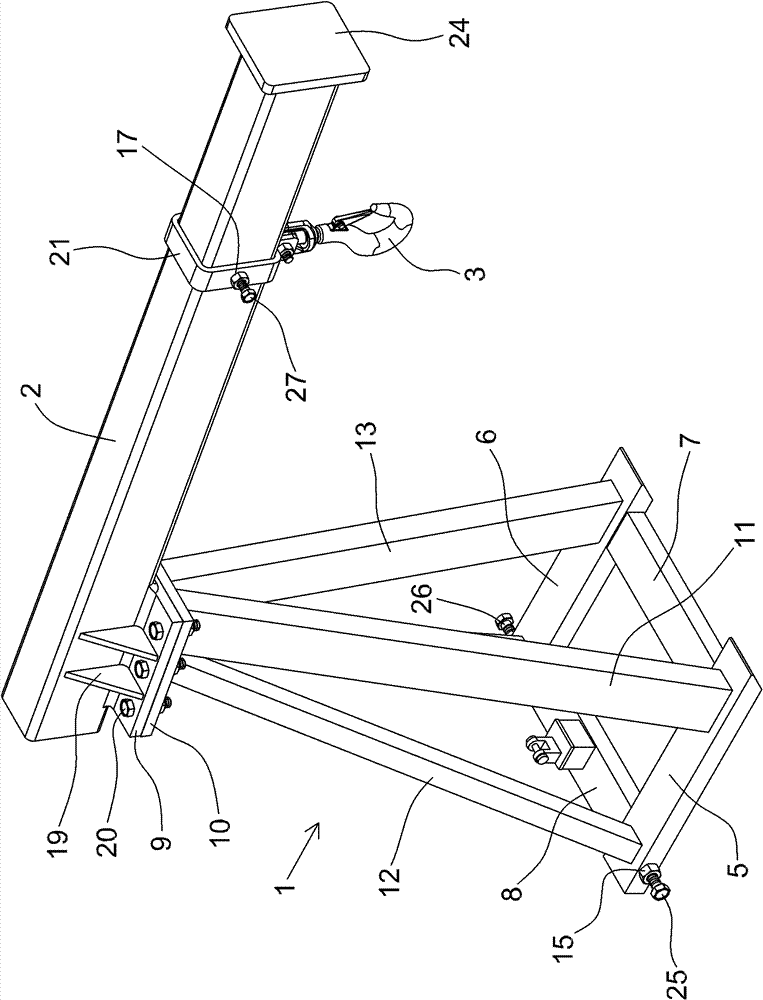

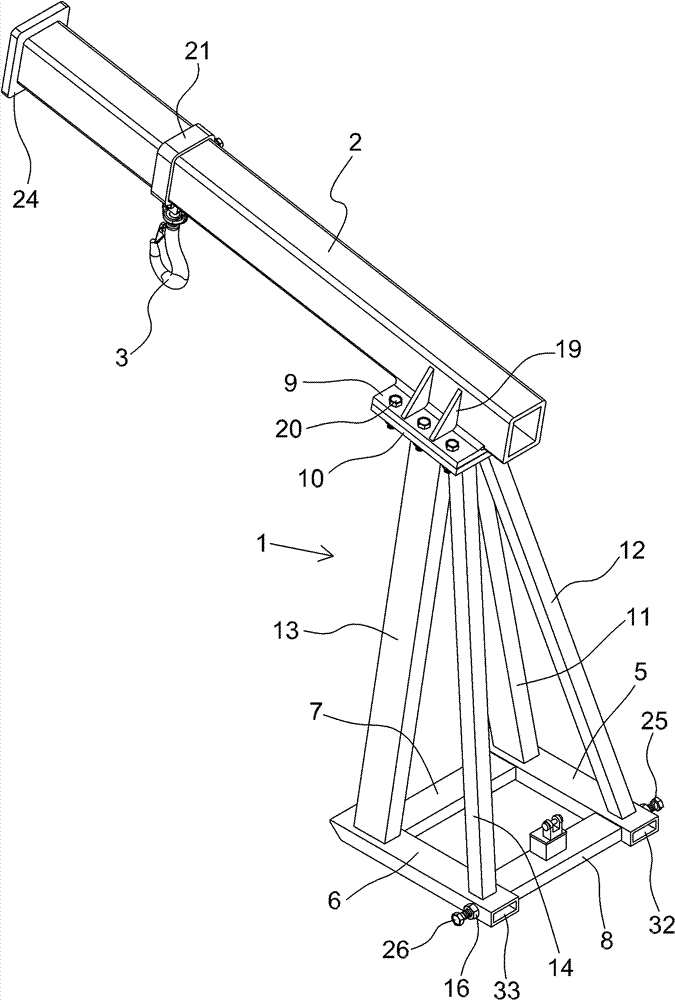

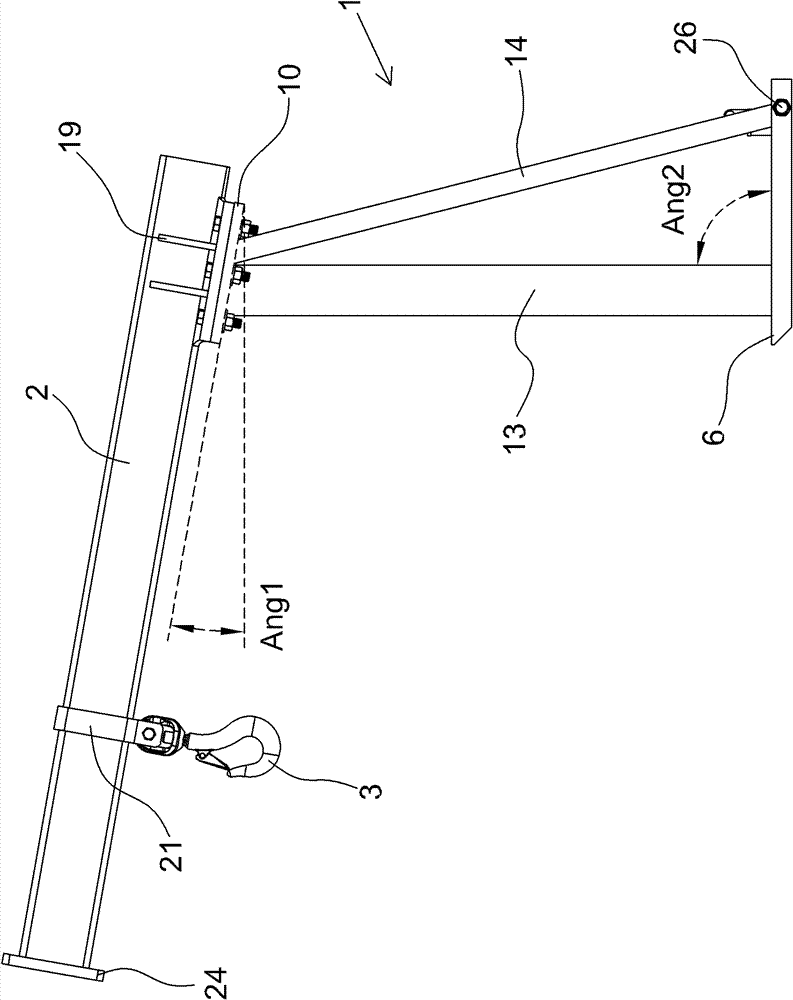

[0029] Label in the figure

[0030] 1 Bracket 2 Cantilever 3 Hook 4 Safety Rope

[0031] 5 left frame 6 right frame 7 front frame 8 rear frame

[0032] 9 Connection plate 10 Top plate 11 Left front pillar

[0033] 12 Left rear pillar 13 Right front pillar 14 Right rear pillar 15 Nut

[0034] 16 Nut 17 Nut 18 Connection seat

[0035] 19 Rib 20 Bolt Fastener 21 Lifting Ring 22 Lug

[0036] 23 pin shaft 24 baffle plate 25 locking screw 26 locking screw

[0037] 27 locking screw 28 lifting frame 29 mast 30 forklift

[0038] 31 fork 32 opening 33 opening 34 through hole

[0039] 35 connection seat

[0040] Please refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , the present invention is a special boom for forklifts, including a bracket 1, a cantilever 2, a hook 3, and a safety rope 4. The bracket 1 is composed of a base, four pillars and a top plate. , 6 and horizontal front and rear frames 7,8 are welded, left and right frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com