Method for making and packaging printed circuit board (PCB) and crystal oscillator

A technology for printed circuit boards and crystal oscillators, which can be used in printed circuit manufacturing, printed circuits, and electrical components to assemble printed circuits. Good shielding performance, convenient and accurate positioning and installation and fixing, and the effect of improving product production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. The invention provides a printed circuit board manufacturing method and a packaging method thereof capable of improving product production efficiency and product quality, and a crystal oscillator with the printed circuit board, so as to realize flexible manufacturing and assembly of the crystal oscillator and modification.

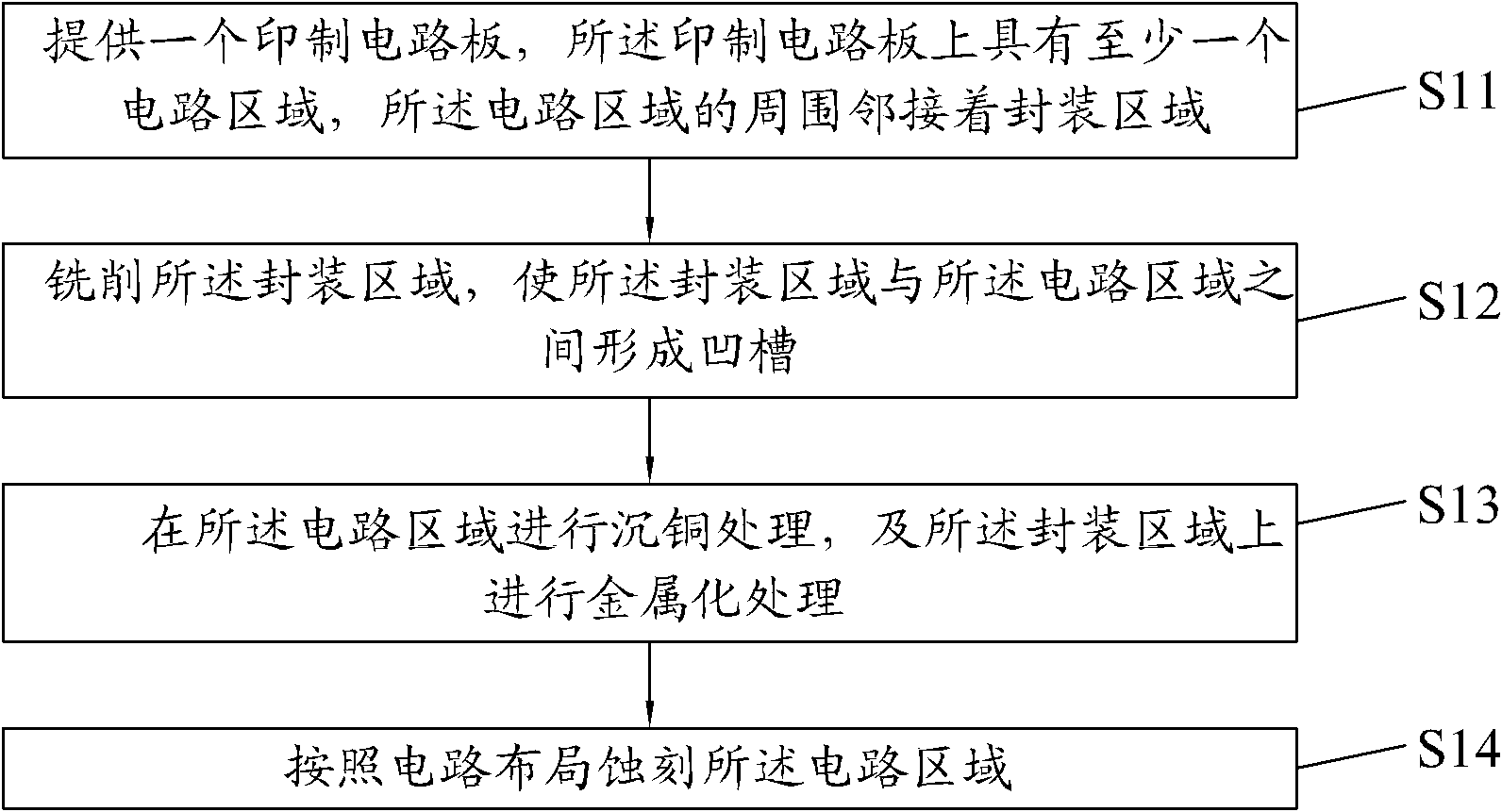

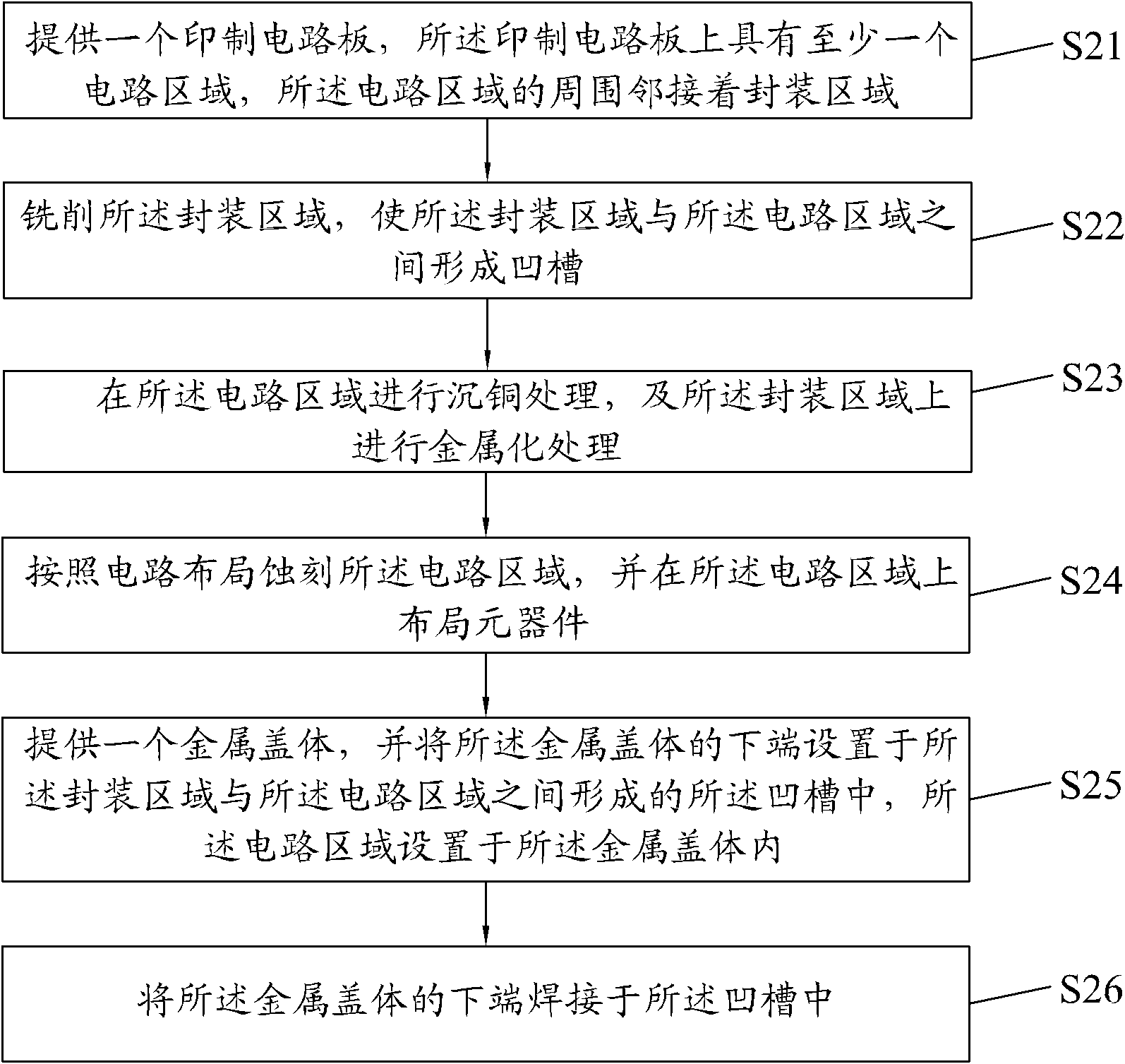

[0024] Such as figure 1 Shown is a flow chart of the method for manufacturing a printed circuit board of the present invention, the steps of the method are as follows: step S11, providing a printed circuit board, the printed circuit board has at least one circuit area, the circuit area The surrounding area is adjacent to the package area; step S12, milling the package area, so that a groove is formed between the package area and the circuit area; step S13, performing copper sinking treatment on the cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com