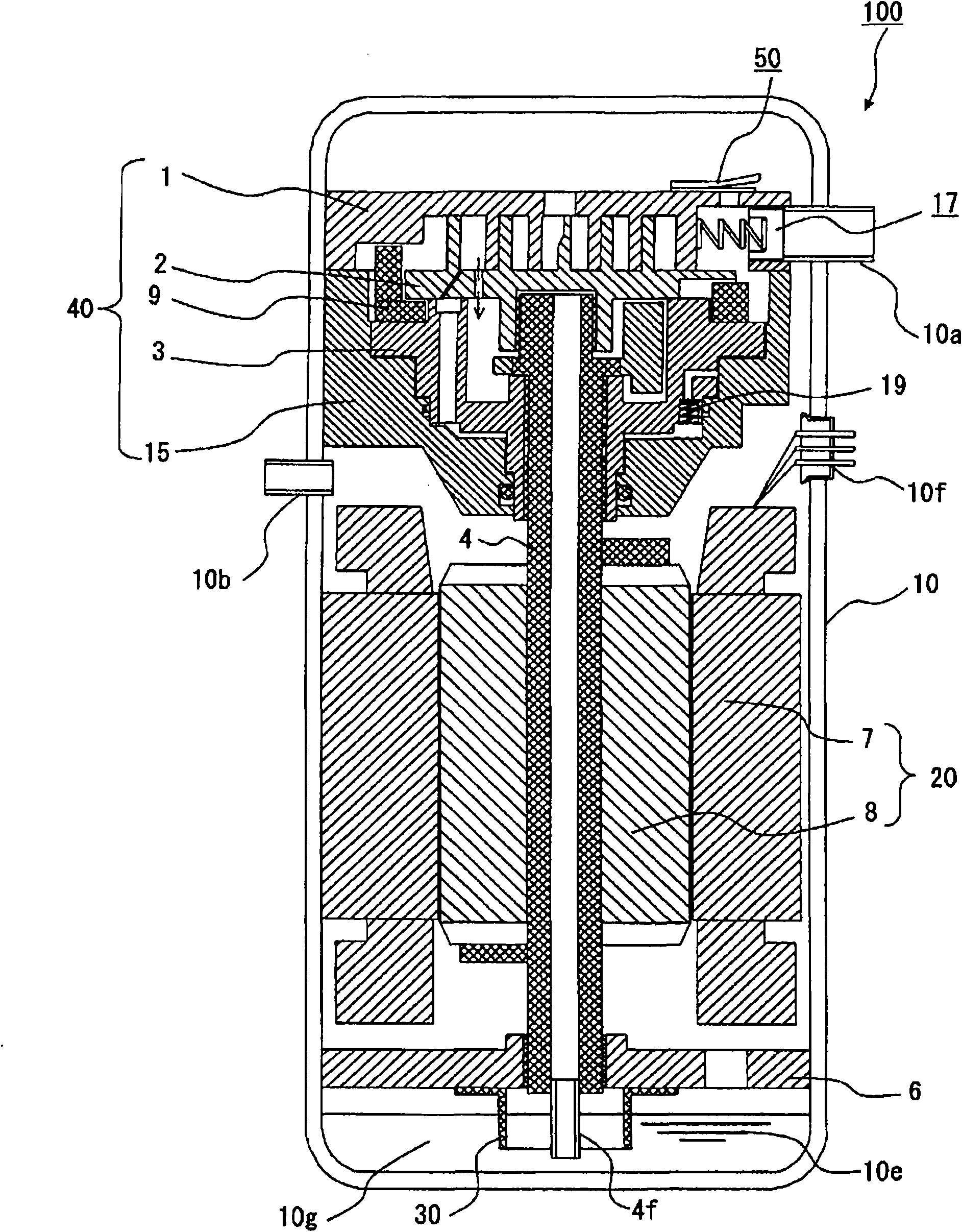

Scroll compressor

A scroll compressor and compression mechanism technology, applied in the field of scroll compressors, can solve problems such as spindle sintering and poor lubrication, and achieve the effect of improving quality and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

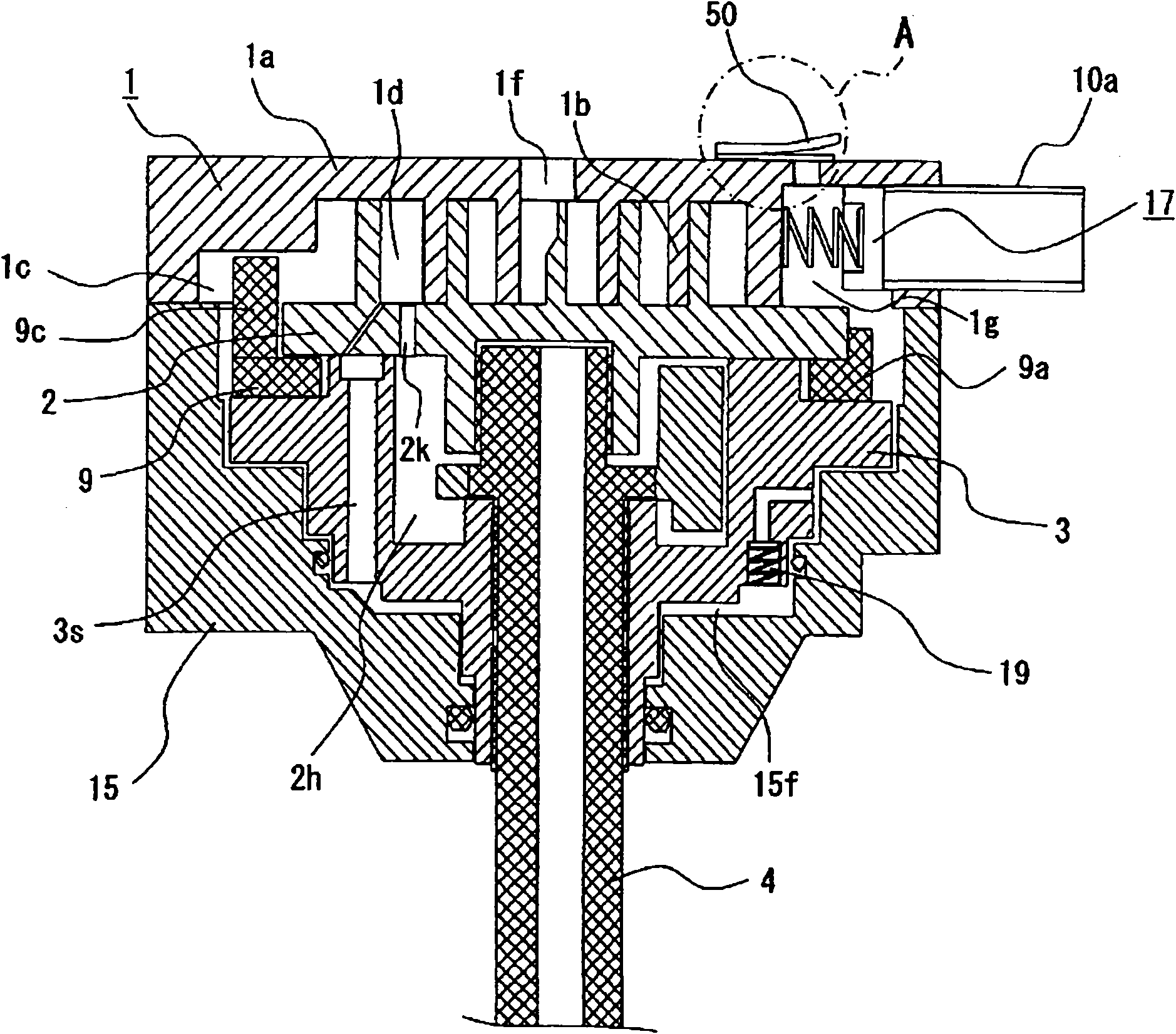

[0063] First, the present embodiment is characterized in the following points.

[0064] (1) Since the discharge space pressure Pd is not greater than the suction space pressure Ps during the reverse rotation of a general scroll compressor, there is no differential pressure between the upper end surface and the lower end surface of the main shaft. Differential pressure oil supply, spindle sintering. However, in the scroll compressor of the present embodiment, since the orbiting scroll is provided with a first communication hole communicating from the compression chamber to the flange portion space in order to reduce the pressure in the flange portion space of the orbiting scroll during counter-rotating operation, In addition, in order to float the flexible frame during reverse operation, a communication hole is provided on the flexible frame to introduce high pressure from the high-pressure suction pressure space to the frame back pressure space, and a check valve is provided o...

Embodiment approach 2

[0264] In general scroll compressors, since the discharge space pressure Pd is not greater than the suction space pressure Ps during reverse rotation, there is no differential pressure between the upper end surface and the lower end surface of the main shaft 4, and therefore, no differential pressure can be applied to the bearing. Oil supply, main shaft 4 sintering.

[0265] The scroll compressor 400 of Embodiment 2 introduces the pressure Pm' (the pressure in the screw in the expansion stroke) lower than the discharge space pressure Pd in the screw into the upper end space of the main shaft 4 so that it can pass through the discharge difference during reverse rotation. The pressure oil supply method supplies oil to each bearing part, and the communication hole 2n to the flange part space 2h is provided on the swing scroll 2, in order to prevent the refrigerant from flowing into the spiral from the communication hole 2n during forward rotation. And a communication check valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com