High-strength concrete facade cross node constrained by steel mould containing steel reinforcement framework

A high-strength concrete and steel skeleton technology, applied in the direction of building reinforcements, structural elements, columns, etc., can solve the problems of low bearing capacity of cross joints, difficulty in meeting the requirements of strong joints, and difficulty in ensuring construction quality, so as to facilitate construction and ensure Ductility of joints, effect of reducing project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

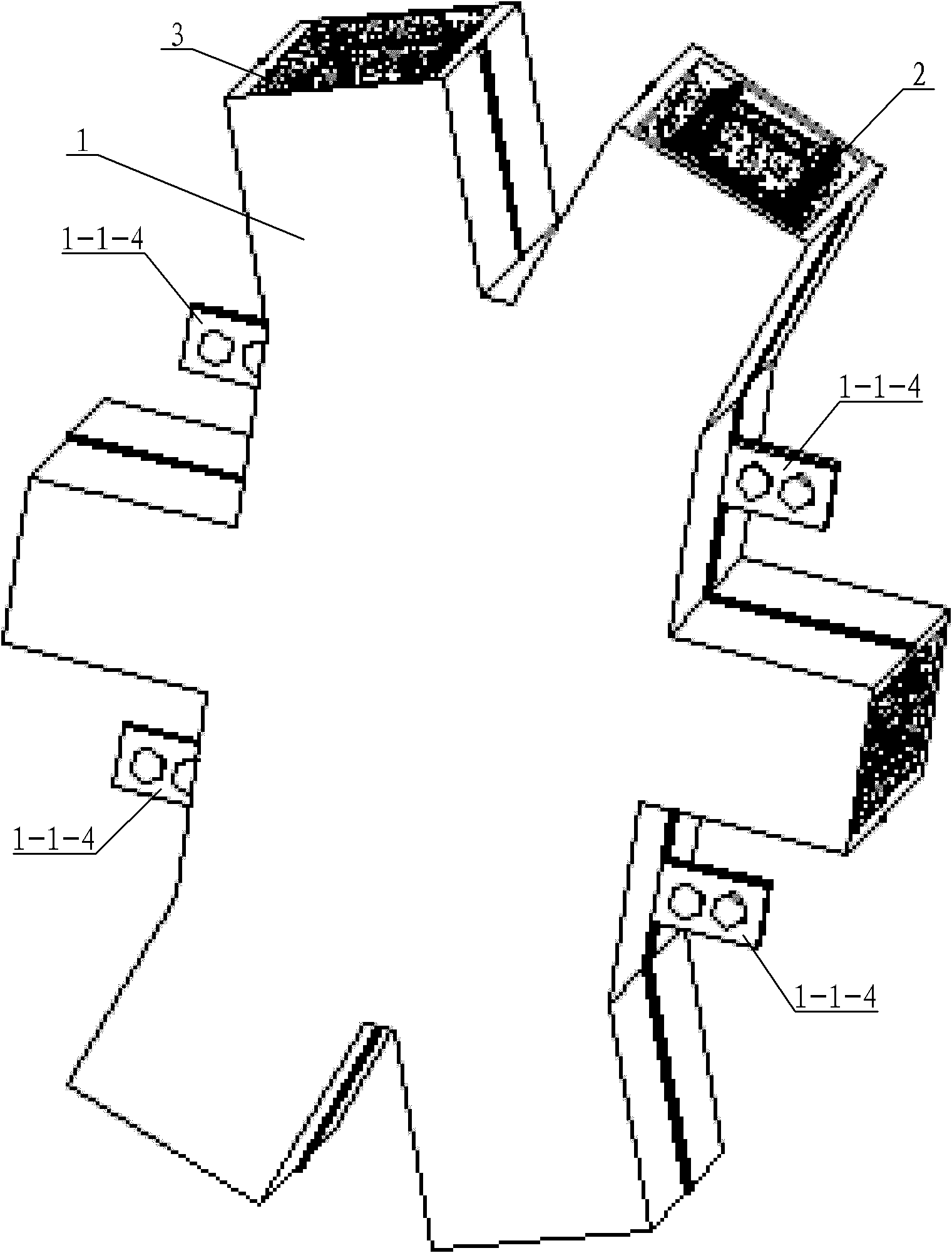

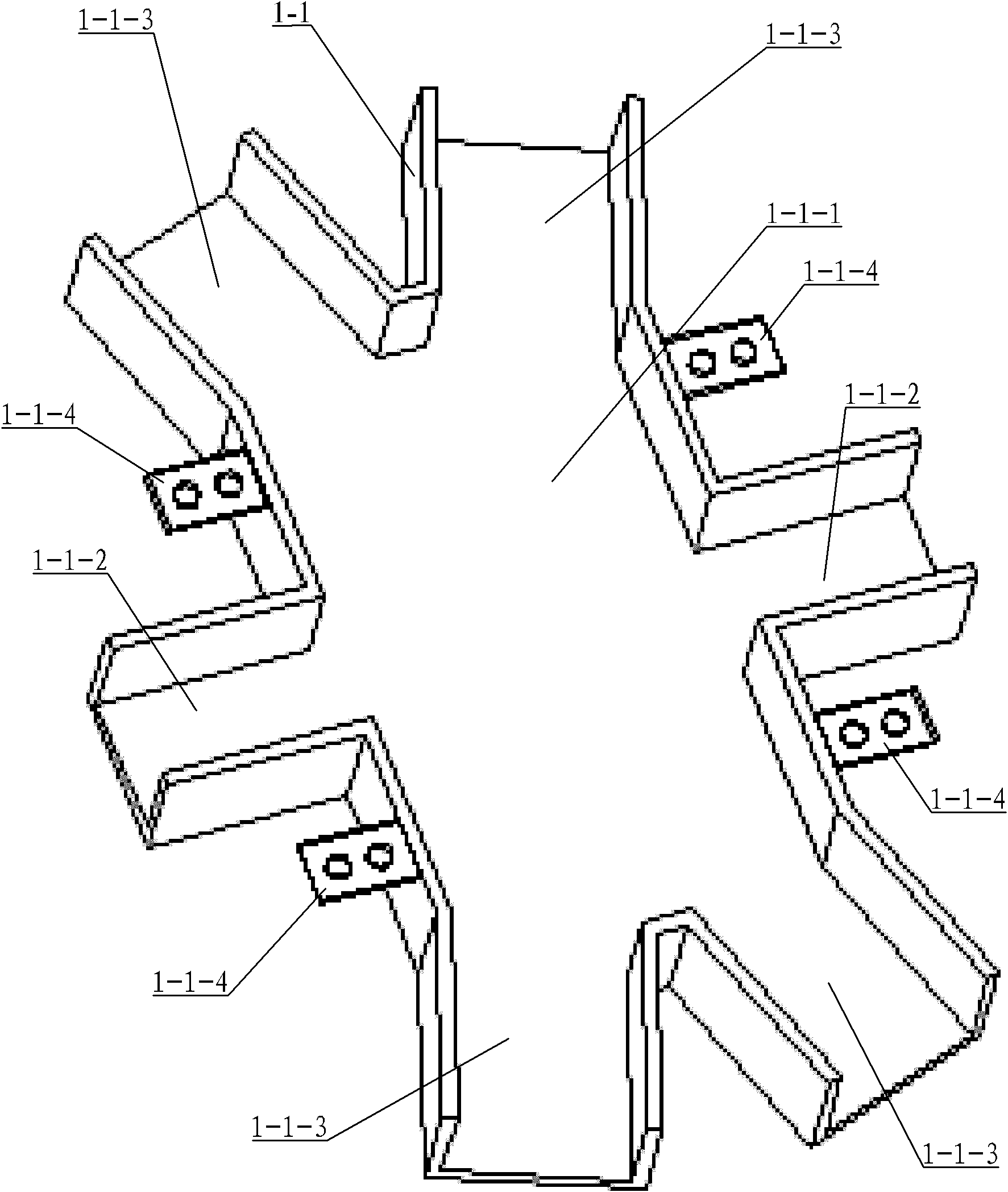

[0007] Specific implementation mode one: combine Figure 1 to Figure 4 Describe this embodiment, this embodiment comprises steel plate formwork 1, steel bar skeleton 2 and high-strength concrete 3, described steel plate formwork 1 is made up of two pieces of channel-shaped steel plates 1-1 buckled together, and each piece of channel-shaped steel plate 1-1 is made of An integrated groove-type vertical die 1-1-1, two groove-type horizontal dies 1-1-2 and four groove-type oblique dies 1-1-3, two groove-type horizontal dies 1-1 -2 are arranged symmetrically on the vertical sides of the groove-type vertical die 1-1-1, and two groove-type horizontal dies 1-1-2 are arranged along the horizontal centerline of the groove-type vertical die 1-1-1, The grooves on the two grooved horizontal mold sheets 1-1-2 communicate with the grooves on the grooved vertical mold sheets 1-1-1, and the two grooved oblique mold sheets 1-1-3 in the four grooved oblique mold sheets The mold piece 1-1-3 is l...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination Figure 1 ~ Figure 3 To illustrate this embodiment, each channel-shaped steel plate 1-1 of this embodiment also includes four bolt lugs 1-1-4, and two bolt lugs are arranged above the two groove-shaped horizontal mold pieces 1-1-2 plate 1-1-4, two bolt lugs 1-1-4 are arranged below the two grooved horizontal mold pieces 1-1-2, and the upper two bolt lugs 1-1-4 are arranged symmetrically on On both sides of the groove-shaped vertical mold sheet 1-1-1, the two lower bolt lugs 1-1-4 are symmetrically arranged on both sides of the groove-shaped vertical mold sheet 1-1-1. Other components and connections are the same as those in the first embodiment.

[0009] During the use of the present invention, one, earlier the horizontal steel bar frame 2-1 and two oblique steel bar frames 2-2 are bound and formed respectively, utilize vertical bar 2-3 and stirrup bar 2-4 to horizontal steel bar frame 2-1 and two The inclined steel frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com