Preparation method of metal thin film having high strength and high ductility

A metal thin film, high-strength technology, applied in the direction of metal material coating process, superimposed layer plating, ion implantation plating, etc., can solve the problems of unusable, small geometric scale of thin film materials, etc., to ensure ductility, good The effect of controllability and excellent comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

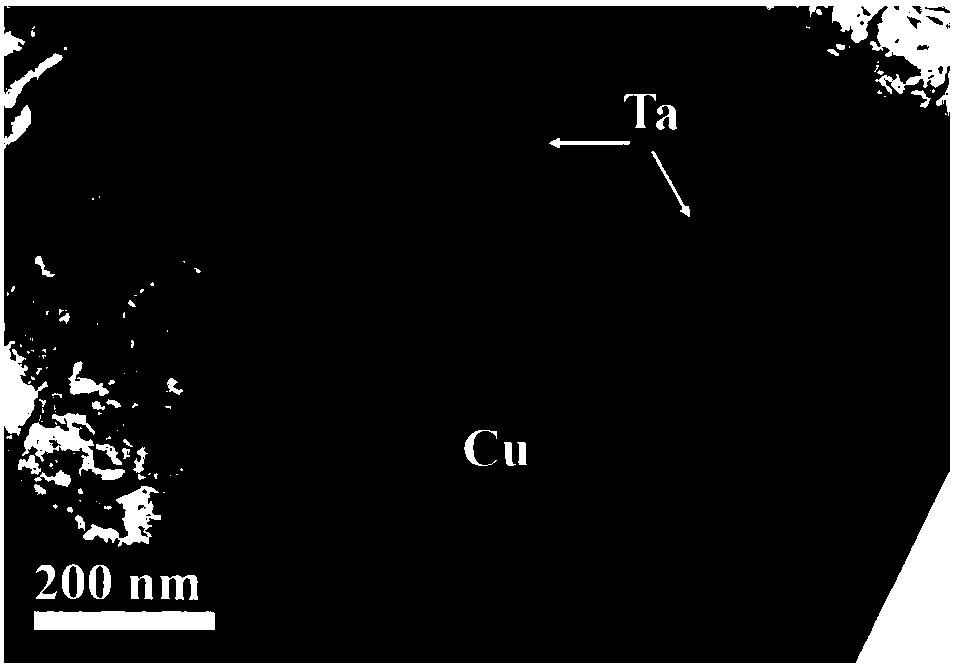

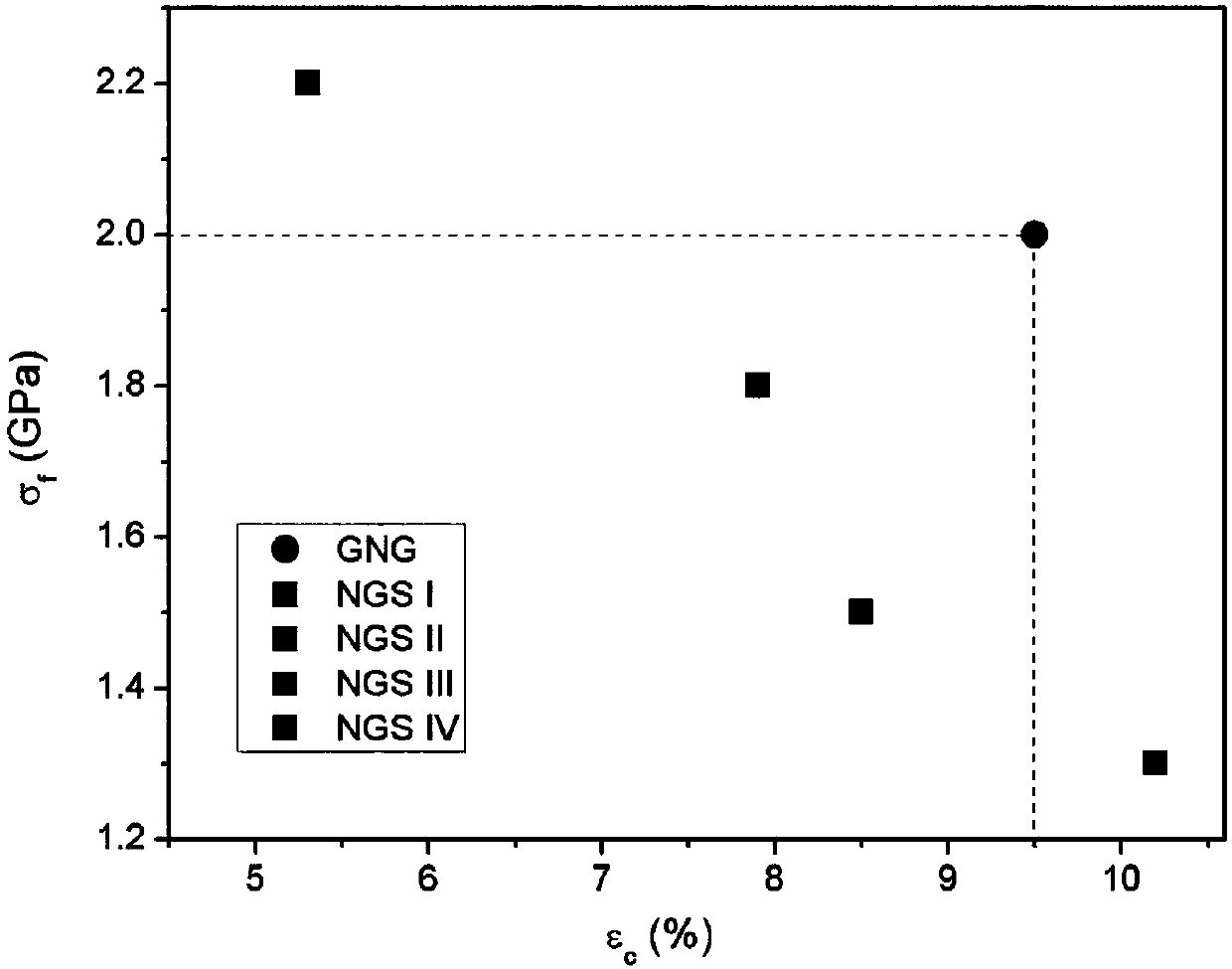

[0016] We choose the metal Cu film as the research object, introduce the ultra-thin metal Ta film with high thermal stability as the separation layer, and separate the Cu film into different thicknesses to form a gradient structure. Using DC magnetron sputtering technology to prepare metal films with inhomogeneous gradient structure, the sputtering targets are 99.99wt% Cu, 99.9wt% Ta and 99.9wt% Ti, and the substrate is a flexible organic PI film. The thickness is 12.5 μm. Before deposition, the PI substrate was cleaned by acetone and ethanol and ultrasonicated for 20 minutes to remove surface dust and oil stains to improve the adhesion of the film to the substrate, then load the target and PI substrate, and start the vacuum chamber Vacuum.

[0017] The gradient structure Cu metal film and uniform structure Cu metal film were prepared respectively:

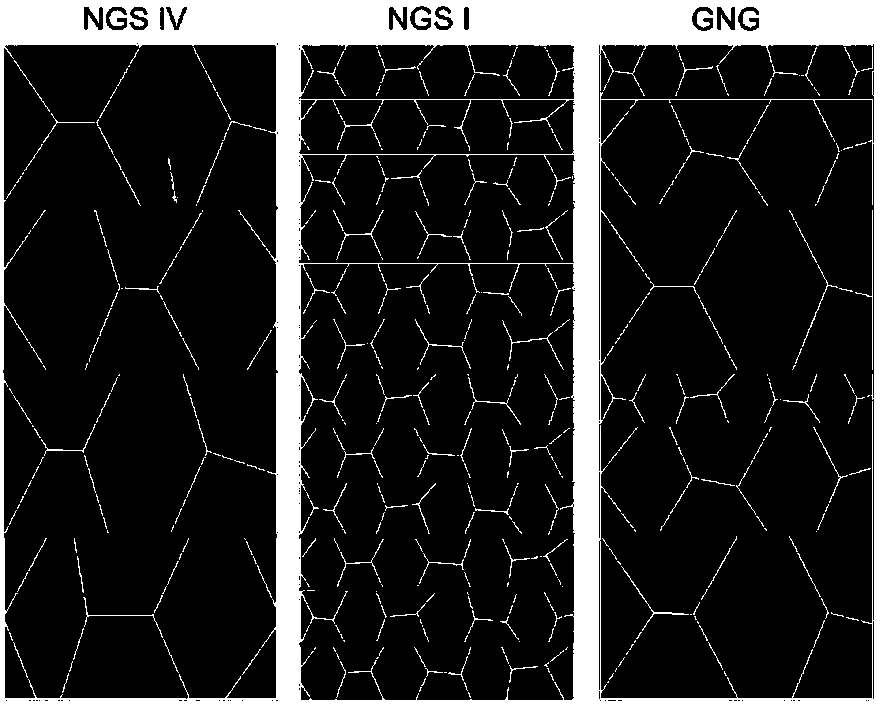

[0018] (a) Cu metal film with gradient structure. The gradient film has the characteristics of a gradient distribution of sin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com