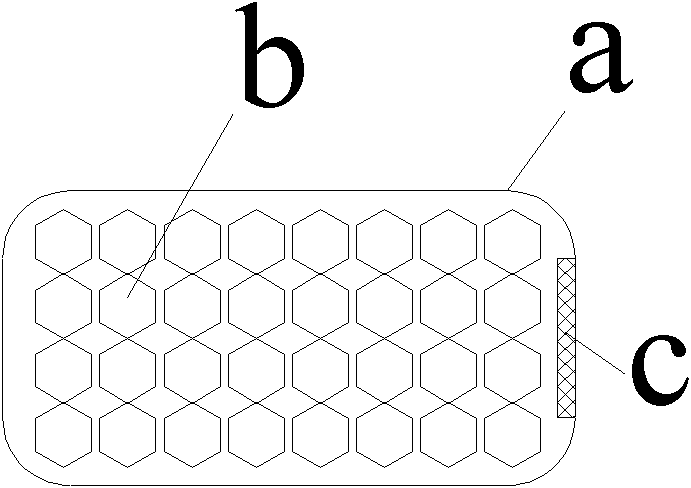

Biological filler bag and application thereof in sewage treatment

A technology of biological filler and filling filler, which is applied in the direction of biological water/sewage treatment, sustainable biological treatment, water/sludge/sewage treatment, etc. Poor problems, to achieve the effect of facilitating microbial attachment, contributing to pollution degradation, and improving capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

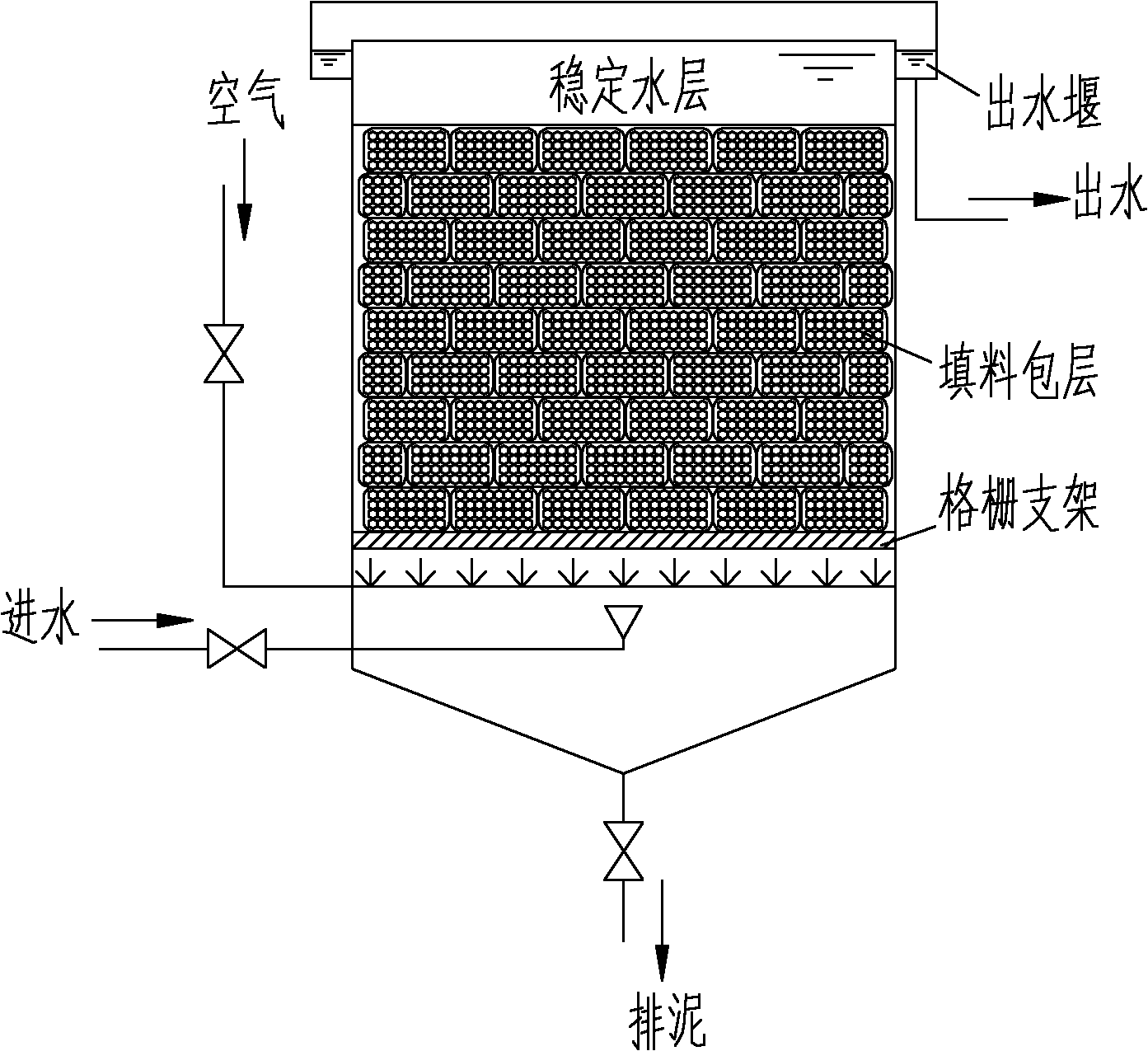

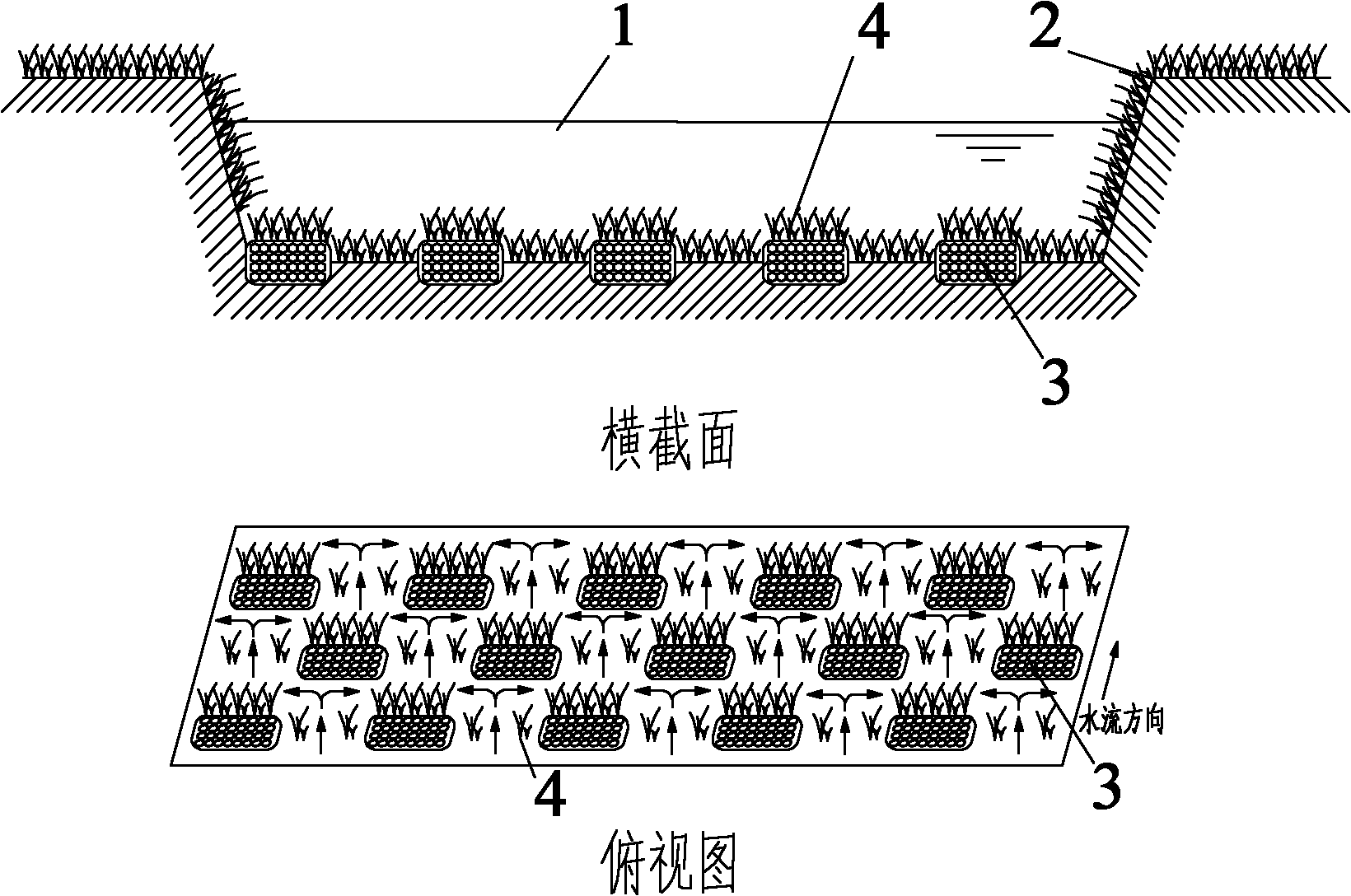

Method used

Image

Examples

Embodiment 1

[0047] The production method of the fiber cloth is as follows: the polyester fiber with a diameter of 6dtex and a length of 46mm is made into a polyester fiber with a length of 5000cm, a width of 400cm, a thickness of 4mm, and a weight of 400g / m 2 Needle-punched nonwoven fabric (produced by Taizhou Southwest Nonwoven Fabric Factory according to the above formula, the same below).

Embodiment 2

[0049] The production method and production length and width are the same as in Example 1, the material used is polypropylene fiber with a diameter of 7dtex and a length of 55mm, and the thickness of the obtained fiber cloth is 5mm, and the grammage is 200g / m 2 .

Embodiment 3

[0051] Manufacture method and manufacture size are with embodiment 1, and used material is the polyester fiber (mass fraction is 50%) of diameter 5dtex, length 55mm and the polypropylene fiber (mass fraction is 50%) of diameter 3dtex, length 45mm, makes fiber Book weight is 260g / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com