Method for installing modular side wall of railway passenger car

An installation method and technology for railway passenger cars, which are applied to railway car bodies, railway car body parts, transportation and packaging, etc., can solve the problems of cumbersome construction, messy production site, low assembly efficiency, etc., and achieve easy maintenance and repair, and high production efficiency Improvement and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

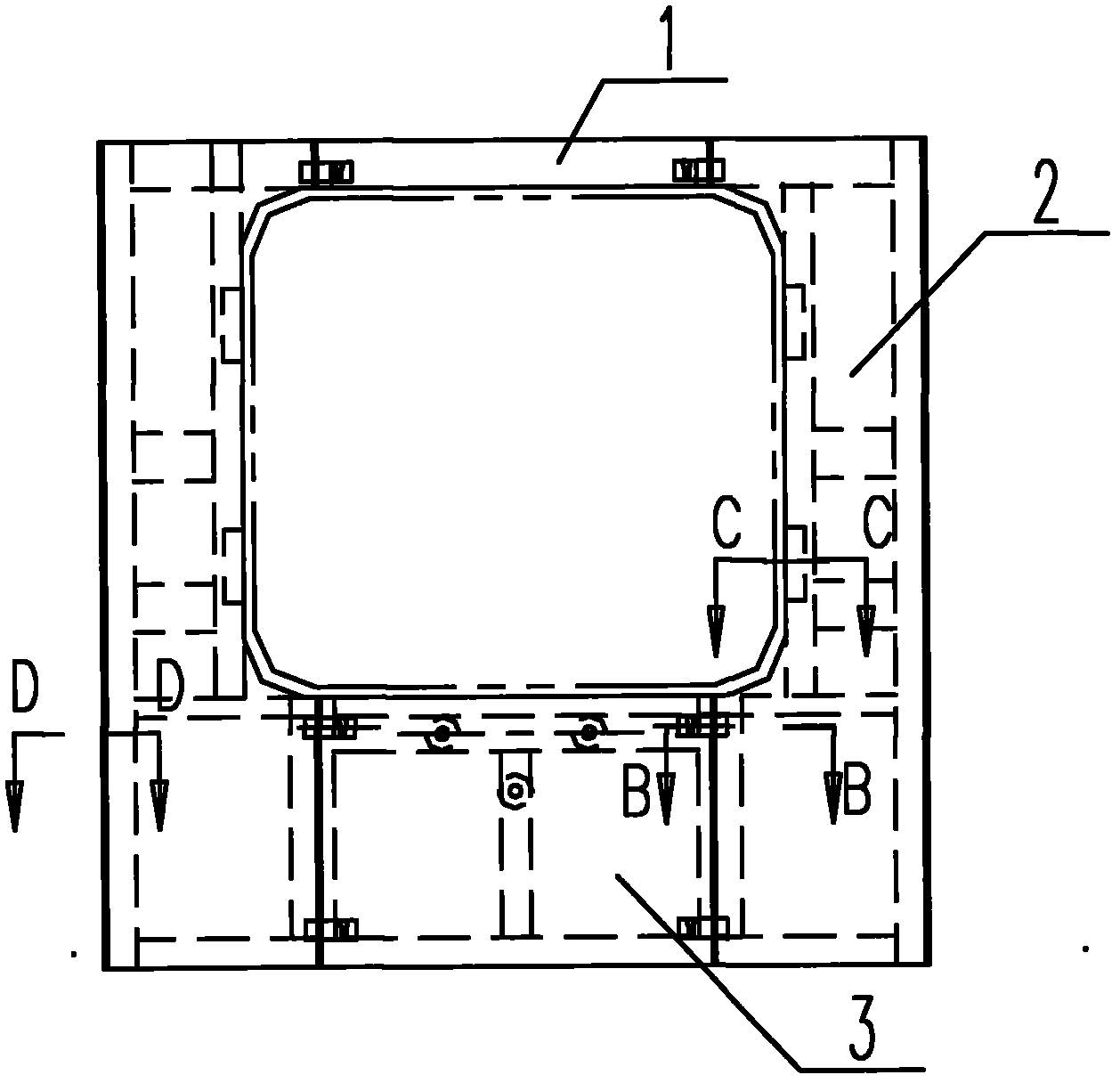

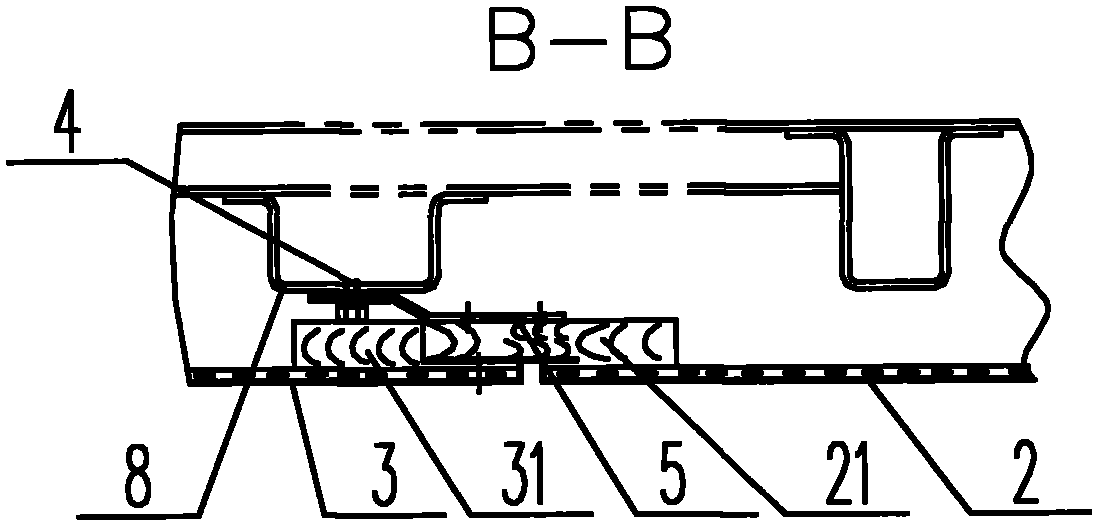

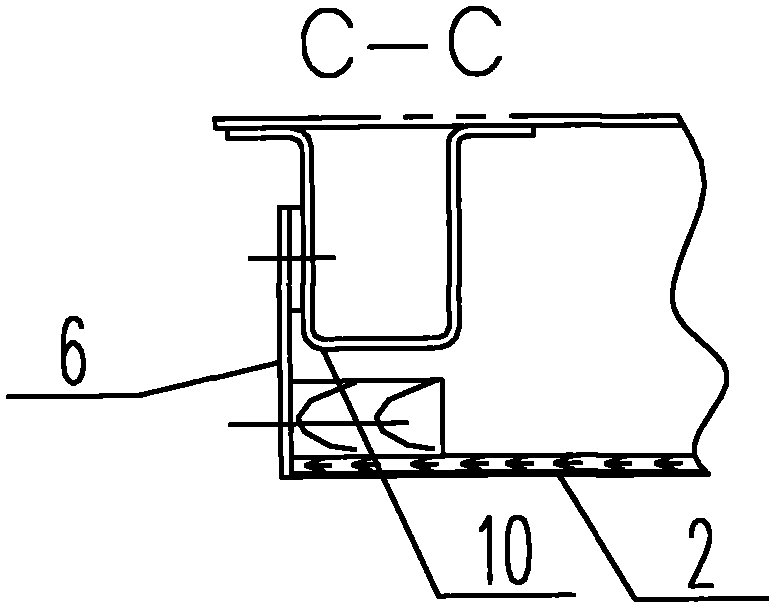

[0020] The railway passenger car modularized side wall installation method of the present invention, as Figure 1-4 As shown, the modular side wall includes the window side wall panel 2, the window middle wall panel 1, 3, the window side wall panel 2 inner side wooden frame 21 protrudes outward, and the window middle wall panel 3 (in this embodiment, the window middle wall panel 3 For example, the structure of the wall panel 1 in the window is the same as this) the outer wooden frame 31 is concave, and the two are matched, and the specific installation steps are as follows:

[0021] The first step, fix the connection iron 5 on the inner wooden frame 21 of the window side wall panel 2;

[0022] In the second step, the half I-shaped mounting seat 7 is fixed on the partition wall 9 of the car body, and its opening direction is towards the window;

[0023] In the third step, the outside of the window side wall panel 2 is inserted into the half I-shaped mounting seat 7;

[0024] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com