Roller for omni-directional wheel

An omnidirectional wheel and roller technology, applied in the omnidirectional field, can solve the problems of reducing the effective load, increasing the difficulty of driving, losing driving power, etc., and achieving the effect of high utilization rate of driving power, scientific and reasonable use, and large effective load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

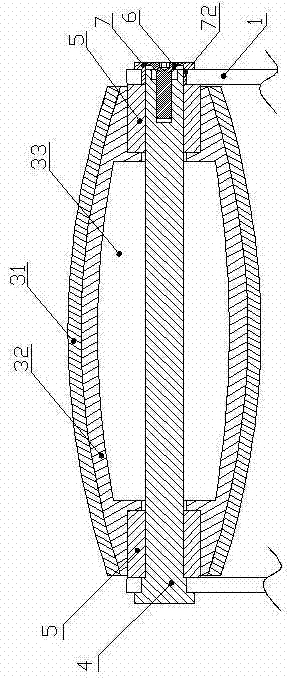

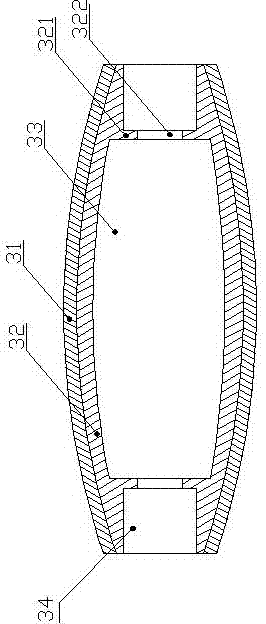

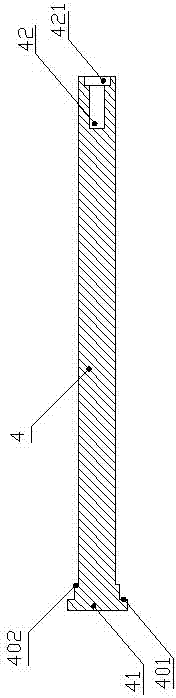

[0019] Rollers for omnidirectional wheels, including roller 3, the outer edge of roller 3 adopts involute track, roller 3 is a whole, the diameter of the middle part is larger than the diameter of both sides, roller 3 includes roller main body 32 and roller jacket 31 . The thickness of each part of the roller main body 32 is consistent. The outer layer of the roller main body 32 is a roller jacket 31. The inner and outer surfaces of the roller jacket 31 are completed by mold opening. The material is cast polyurethane elastomer or rubber. The roller main body 32 is provided with a cavity 33 inside, and the two ends of the roller main body 32 are symmetrically provided with bearing cavities 34 . The bearing cavities 34 are provided with inner bosses 321 , and the inner bosses 321 are provided with shaft holes 322 . The roller for the omnidirectional wheel also includes a roller shaft 4, one end of the roller shaft 4 is provided with a boss 41, the boss 41 includes a first boss 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com