Longitudinal cutting device for rubber sheet cooler

A film cooling machine and slitting device technology, which is applied in the field of a device for longitudinally cutting rubber material, can solve the problems of inability to adjust the spacing, large impact of the blade, and shortened life of the knife, so as to achieve extended service life, uniform force, The effect of reducing the deflection force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

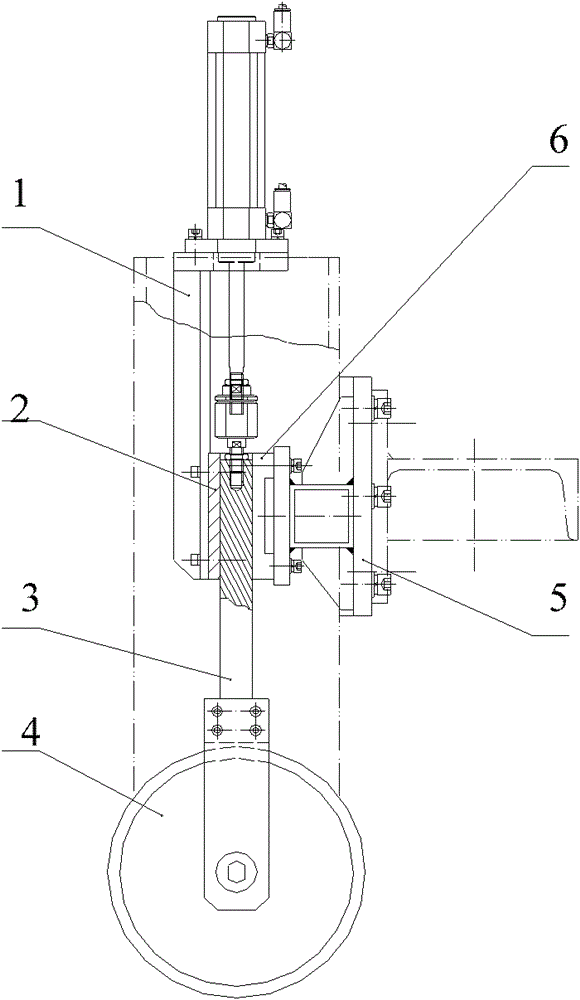

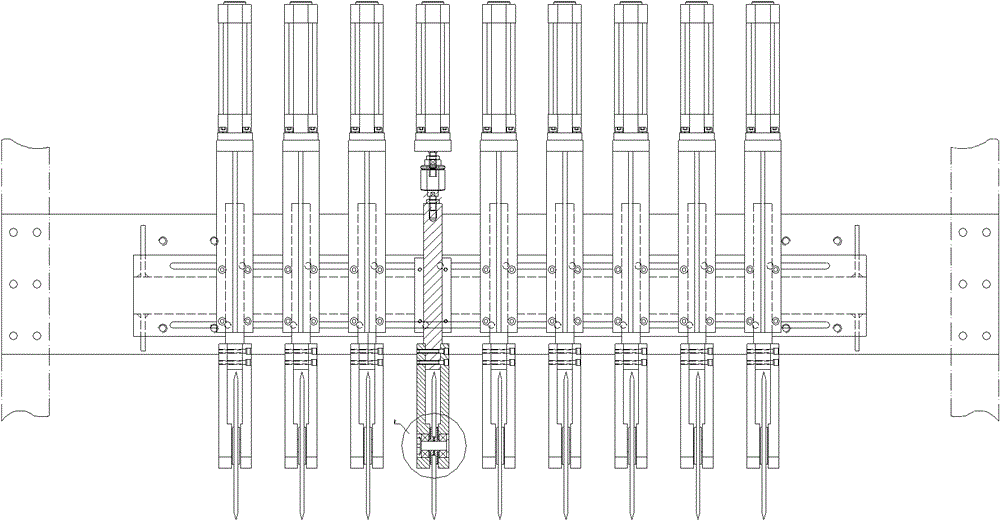

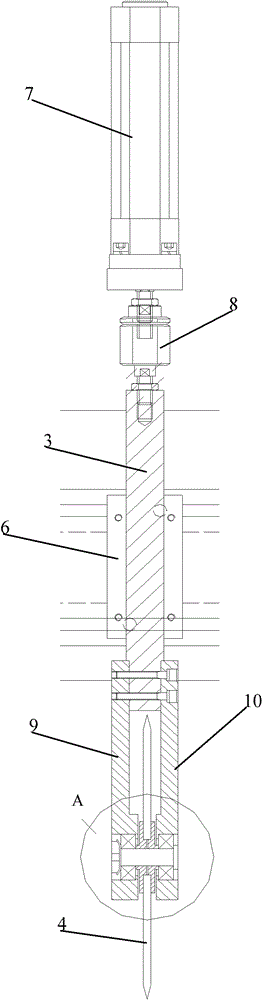

[0018] like Figure 1-3 As shown, the slitting device of the present invention includes a slitting frame 5 and a slitting knife device fixed thereon, and the slitting knife device includes a double-acting cylinder 7 fixed on the support frame 1, and the support The frame is fixed on the slitting frame 7 through a transition block, and the cylinder 7 is fixedly connected with the slitting frame 5 through the support frame 1 . The end of the piston rod of the cylinder 7 is fixedly connected with the slide bar 3, and the slitting knife 4 is fixed on both sides of the lower end of the slide bar 3. The lifting or lowering of the slitting knife 4 can be realized by controlling the cylinder 7, so as to satisfy Work required.

[0019] Wherein, the support frame 1 is fixedly connected with the transition block, and the cylinder is fixedly connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com