Biological functionalized nano titanium material and preparation method thereof

A biofunctionalized, nano-titanium technology, applied in the field of biomedical materials, can solve the problems of inability to combine with surrounding tissues of the human body, low success rate of titanium implant implantation, poor initial stability, etc., to improve proliferation and differentiation ability, good application Promising, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1, biofunctionalized nano-titanium material (TiO 2 Preparation of nanotubes with a diameter of 30nm)

[0032] Include the following steps:

[0033] a. Ultrasonic cleaning the titanium material with acetone, absolute ethanol, and deionized water for 20 minutes in sequence, and drying at 37°C for later use;

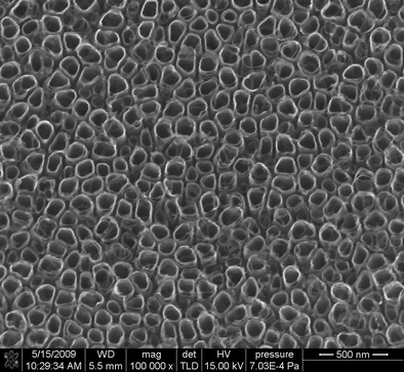

[0034] b, dissolving ammonium fluoride with a volume fraction of 50% ethanol solution to make a solution with a concentration of 0.27mol / L, as the electrolyte; then the titanium material pretreated in step a is used as the anode, and the platinum electrode is used as the cathode. In the above-mentioned ammonium fluoride electrolyte, electrolyze for 3 hours under the action of a direct current of 10V, soak and wash the oxidized titanium material with deionized water for 3 times, and dry at 37°C to obtain TiO with a diameter of 30nm on the surface. 2 The titanium material of the nanotube array, its FE-SEM image is as follows figure 1 shown;

[0035...

Embodiment 2

[0040] Embodiment 2, biofunctionalized nano-titanium material (TiO 2 Preparation of nanotubes with a diameter of 60nm)

[0041] Include the following steps:

[0042] a. Ultrasonic cleaning the titanium material with acetone, absolute ethanol, and deionized water for 20 minutes in sequence, and drying at 37°C for later use;

[0043] b, dissolving ammonium fluoride with a volume fraction of 50% ethanol solution to make a solution with a concentration of 0.27mol / L, as the electrolyte; then the titanium material pretreated in step a is used as the anode, and the platinum electrode is used as the cathode. In the above-mentioned ammonium fluoride electrolyte, electrolyze for 3 hours under the action of a direct current of 20V, soak and wash the oxidized titanium material with deionized water for 3 times, and dry at 37°C to obtain TiO with a diameter of 60nm on the surface. 2 The titanium material of the nanotube array, its FE-SEM image is as follows figure 2 shown;

[0044]...

Embodiment 3

[0046] Embodiment 3, biofunctionalized nano-titanium material (TiO 2 Preparation of nanotubes with a diameter of 100nm)

[0047] Include the following steps:

[0048] a. Ultrasonic cleaning the titanium material with acetone, absolute ethanol, and deionized water for 20 minutes in sequence, and drying at 37°C for later use;

[0049] b, dissolving ammonium fluoride with a volume fraction of 50% ethanol solution to make a solution with a concentration of 0.27mol / L, as the electrolyte; then the titanium material pretreated in step a is used as the anode, and the platinum electrode is used as the cathode. In the above-mentioned ammonium fluoride electrolyte, electrolyze for 3 hours under the action of a direct current of 25V, soak and wash the oxidized titanium material with deionized water for 3 times, and dry at 37°C to obtain TiO with a diameter of 100nm on the surface. 2 The titanium material of the nanotube array, its FE-SEM image is as follows image 3 shown;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com