Three-temperature section food quick freezing method and three-temperature section food quick freezer

A quick-freezing machine and food technology, which is applied in food preservation, food processing, food science, etc., can solve the problems of increasing the energy consumption of quick-freezing machines, and achieve the effects of small heat transfer temperature difference, uniform temperature distribution, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

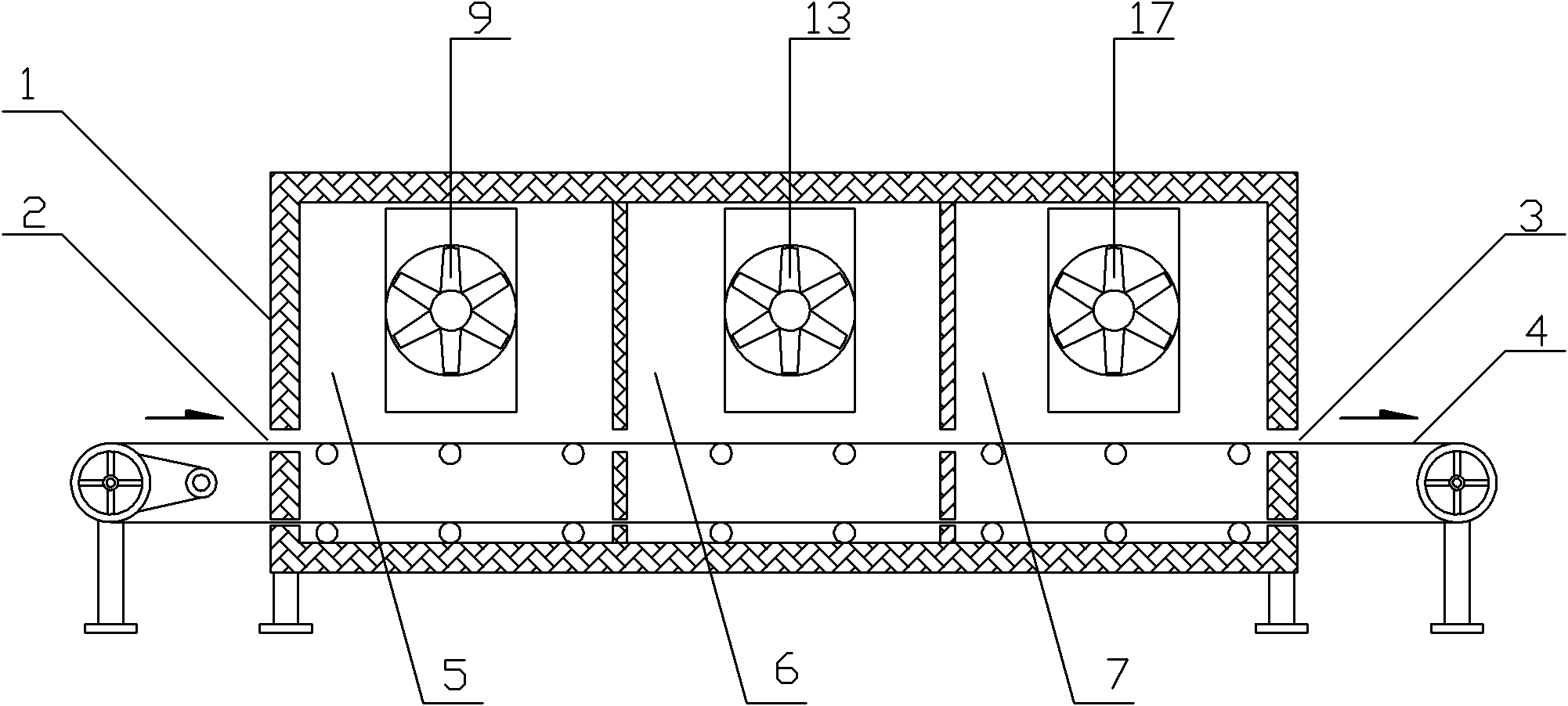

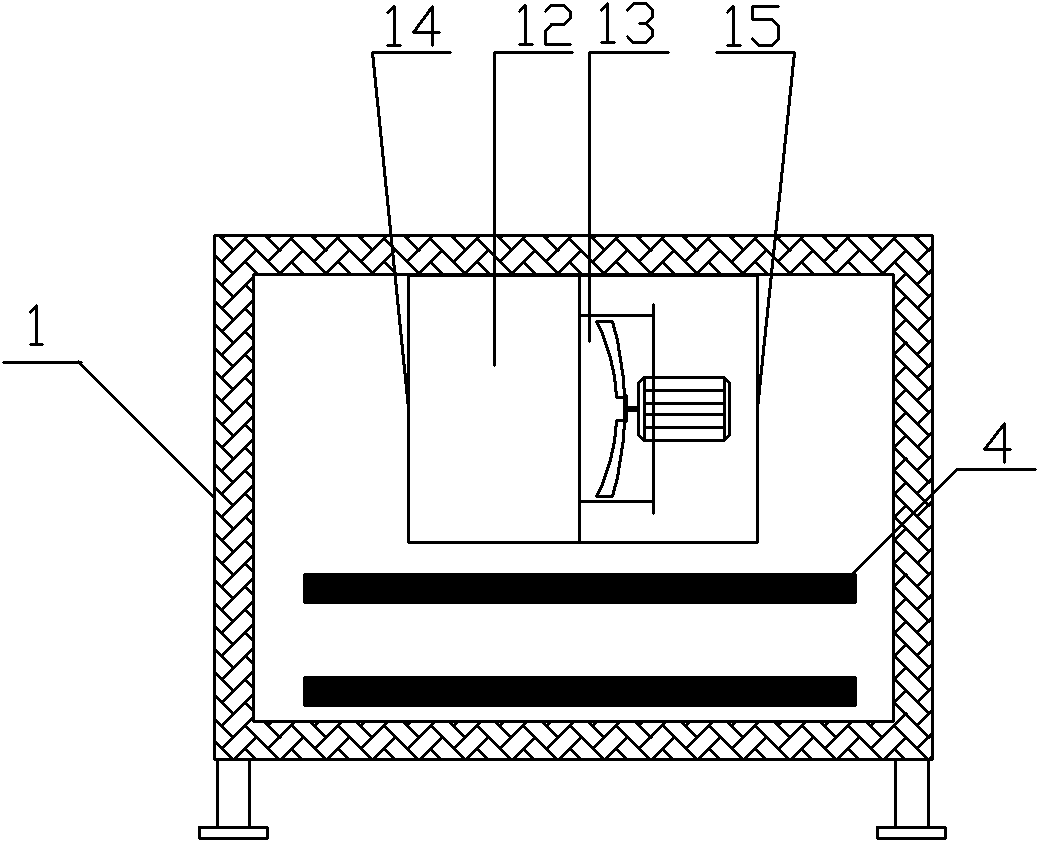

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0016] In the method for quick-freezing food in three temperature sections of the present invention, the food is sequentially passed through the three temperature sections of pre-cooling temperature, crystallization temperature and cryogenic temperature to obtain quick-frozen food; the pre-cooling temperature is -1--5°C, and the food Pre-cooling from the initial temperature to the freezing point temperature, so that the moisture in the quick-frozen food is cooled to a saturated liquid state; the crystallization temperature is -20--25°C. At the crystallization temperature, the food passes through the maximum formation zone of ice crystallization, and the pure The water freezes into crystals from the outside to the inside, so that the water in the quick-frozen food freezes to a saturated solid state; the cryogenic temperature is -38--45°C. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com