Chip-like electric component and method for manufacturing same

A technology of electrical components and electrical components, applied in the direction of electrical components, resistance manufacturing, resistor parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

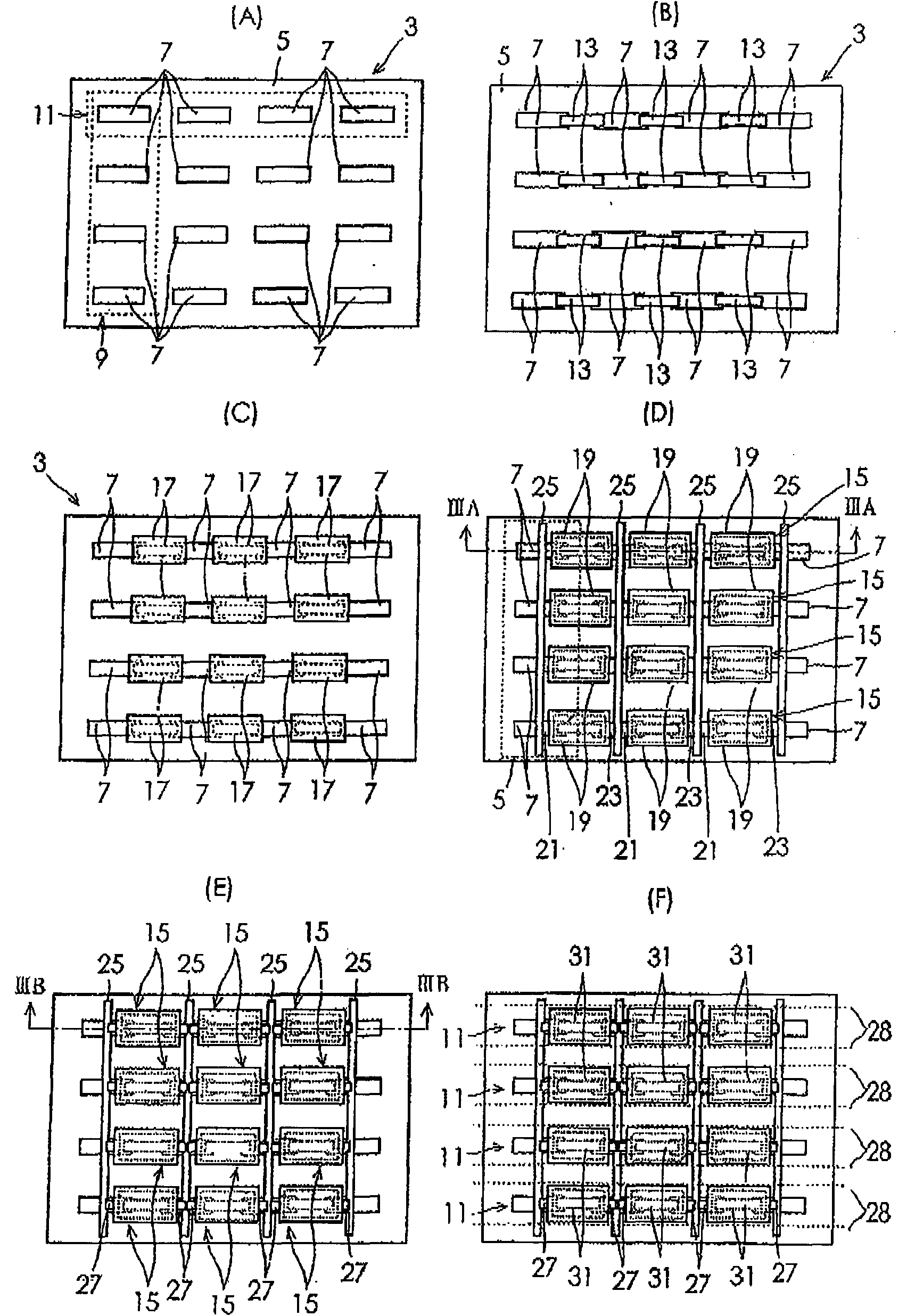

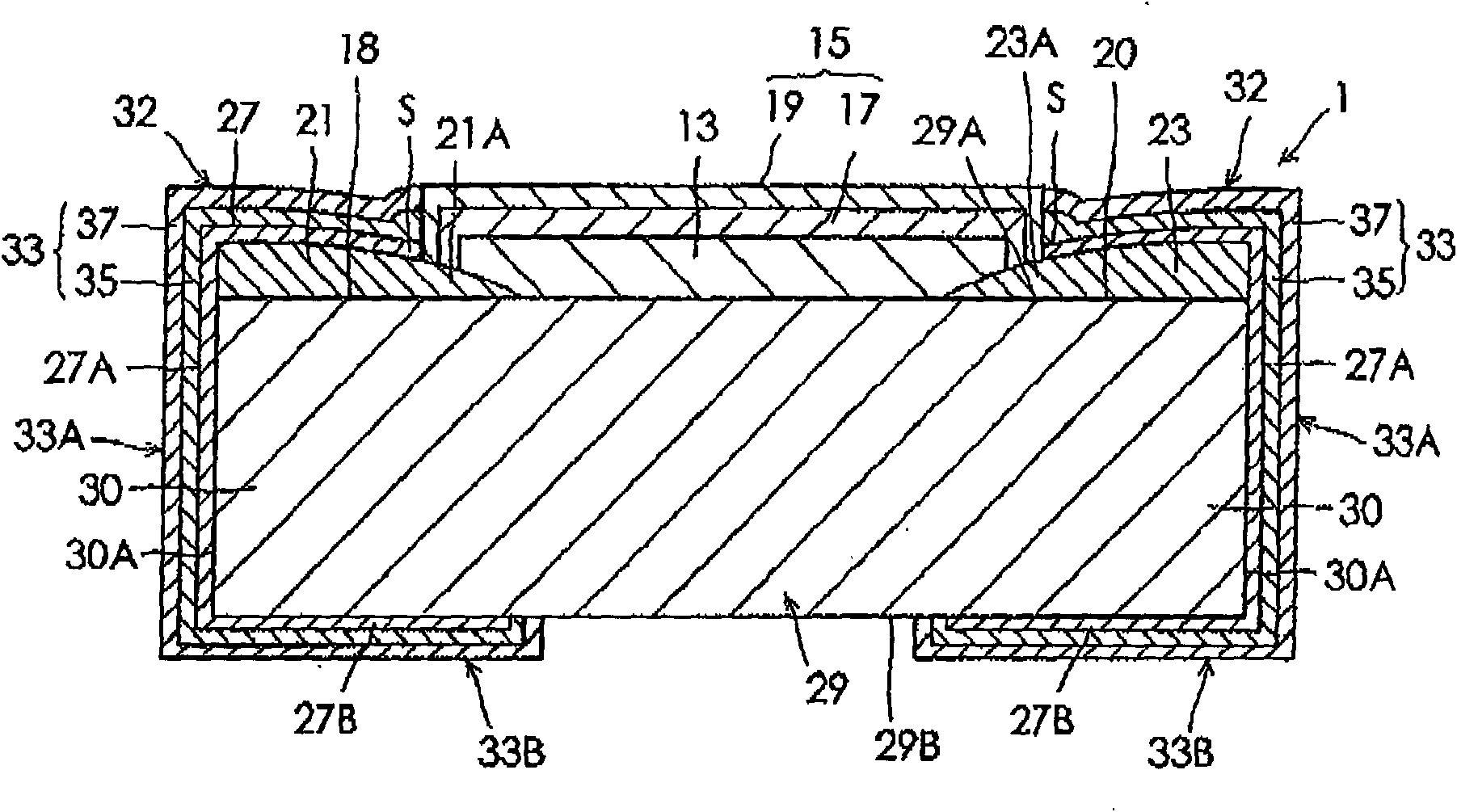

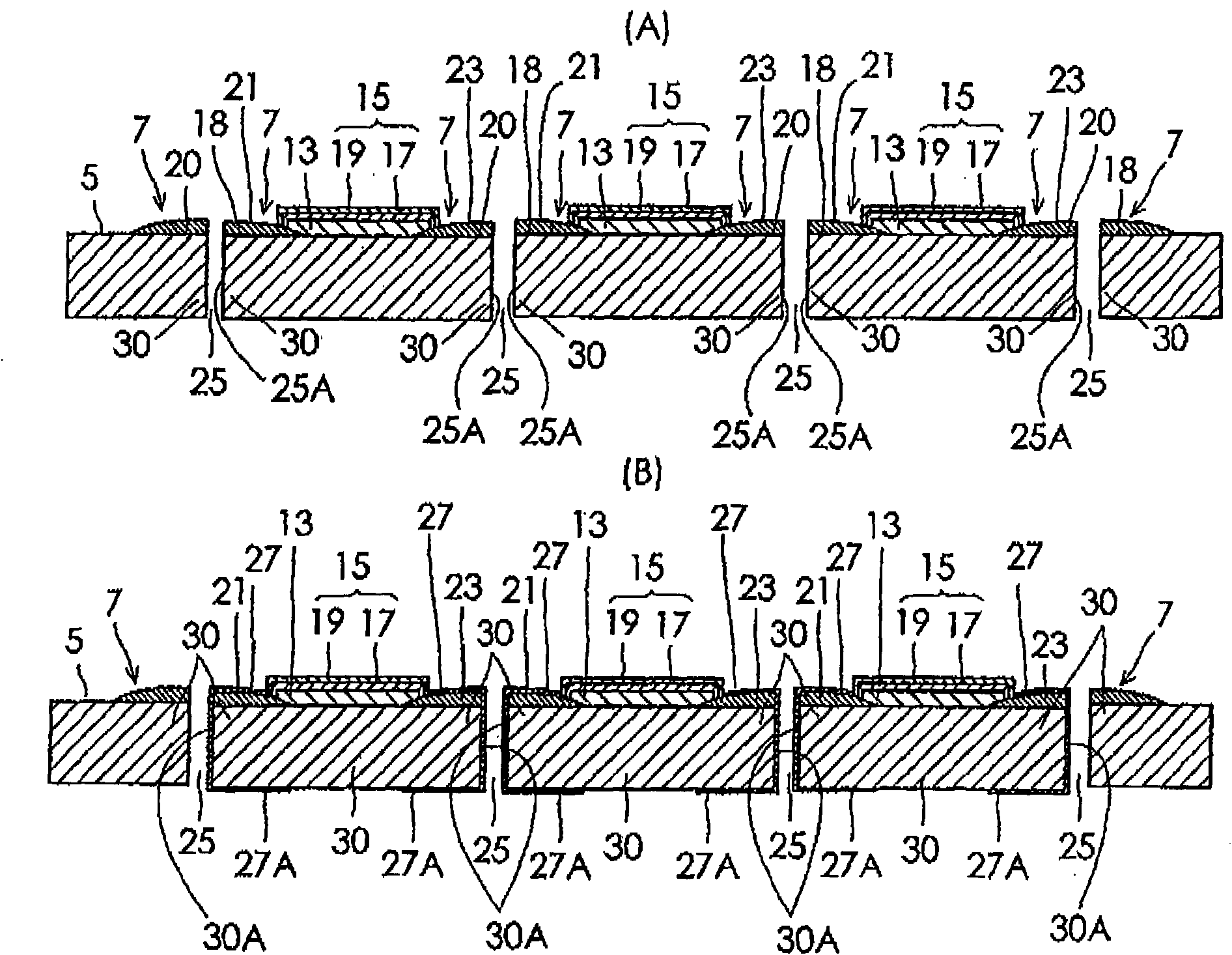

[0022] Hereinafter, embodiments of the chip-shaped electrical component of the present invention will be described in detail with reference to the drawings. figure 1 It is a cross-sectional view schematically showing the structure of a chip resistor 1 which is one type of chip-like electrical component manufactured by the manufacturing method of the chip-like electrical component of the present invention. figure 1 This is a cross-sectional view schematically shown for easy understanding, and the dimensional ratio of each part, the thickness and shape of each layer are different from those of an actual member. figure 2 (A) to (F) are shown figure 1 A process diagram of a plurality of steps in the manufacturing method of the chip resistor 1 according to the embodiment. use figure 2 process diagrams, while describing the manufacturing method of the chip resistor 1 of this embodiment, together with figure 1 The structure of the chip resistor 1 will be described.

[0023] exi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com