Trenchless buried type high voltage power cable bellows

A technology of high-voltage electric power and cable corrugation, which is applied in the field of power cables, can solve the problems of hidden quality problems in welded connections, reduce the overall quality of MPP pipes, affect urban traffic, and operation, and achieve excellent anti-aging performance, good resistance to uneven settlement, Conducive to the effect of construction and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

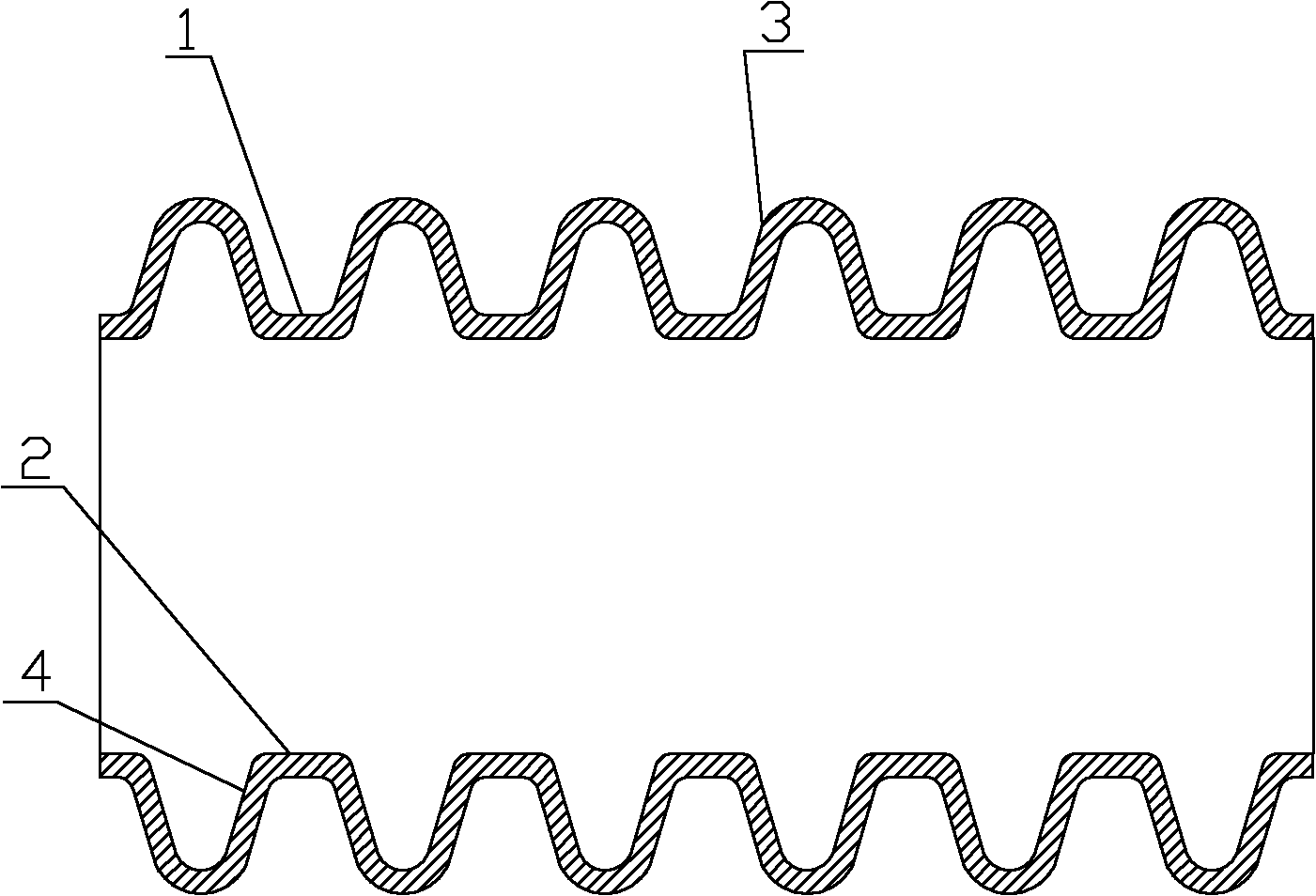

[0038] Such as figure 1 As shown, the inner and outer walls 2 and 1 of the corrugated pipe are formed with a corrugated convex ring 3 with an arc-shaped bottom and a corresponding corrugated groove ring 4 with an arc-shaped bottom. The radial cross-section of the corrugated pipe is concentric with the circumference, and the raised ring part 3 and the corresponding corrugated grooved ring part 4 are regularly arranged along the length of the pipe at a fixed distance and extend infinitely, forming mutually independent corrugated structures. This corrugated structure not only improves the moment of inertia of the pipe, but also improves the overall performance of the pipe, and at the same time, the flexibility of the pipe is greatly improved, and it can be coiled with a certain length; the ductility and good bendability of the present invention are specifically If the corrugated tube of the present invention is bent into a circle, the distance between the adjacent raised ring par...

Embodiment 4-6

[0065] Except that the material of the corrugated pipe is chlorinated polyvinyl chloride (PVC-C), the same as in Embodiment 1-3, the non-excavation buried high-voltage power cable corrugated pipe of the present invention was obtained.

[0066] According to the non-excavation buried high-voltage power cable bellows of the present invention, it is not necessary to excavate the ground during underground construction, and has no major impact on urban traffic and operation; it is formed by the raised ring part and the grooved ring part. The gap and the selection of the pipe body material make it have good bendability and moderate ductility. In the case of tortuous and circuitous laying lines, the present invention can be used for natural bending to comply with the complex and changeable laying lines; the coiled bellows The small footprint is beneficial for construction and transportation in a narrow environment. At the same time, there is no need for joints connected by pipes, which...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com