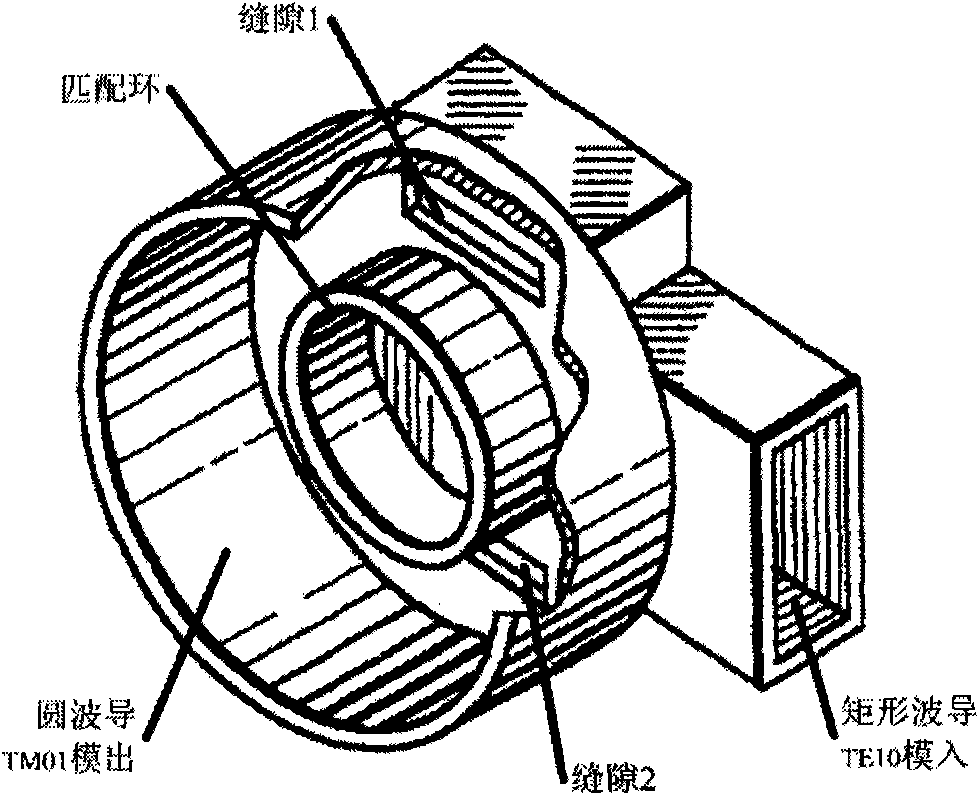

Ka frequency range high-power waveguide rotary joint

A rotary joint, high-power technology, applied in waveguide-type devices, electrical components, circuits, etc., can solve the problems of increased frequency dependence, unfavorable use of high-power, and narrowing of the suppression bandwidth, reducing insertion loss, beneficial to High power use, the effect of achieving smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

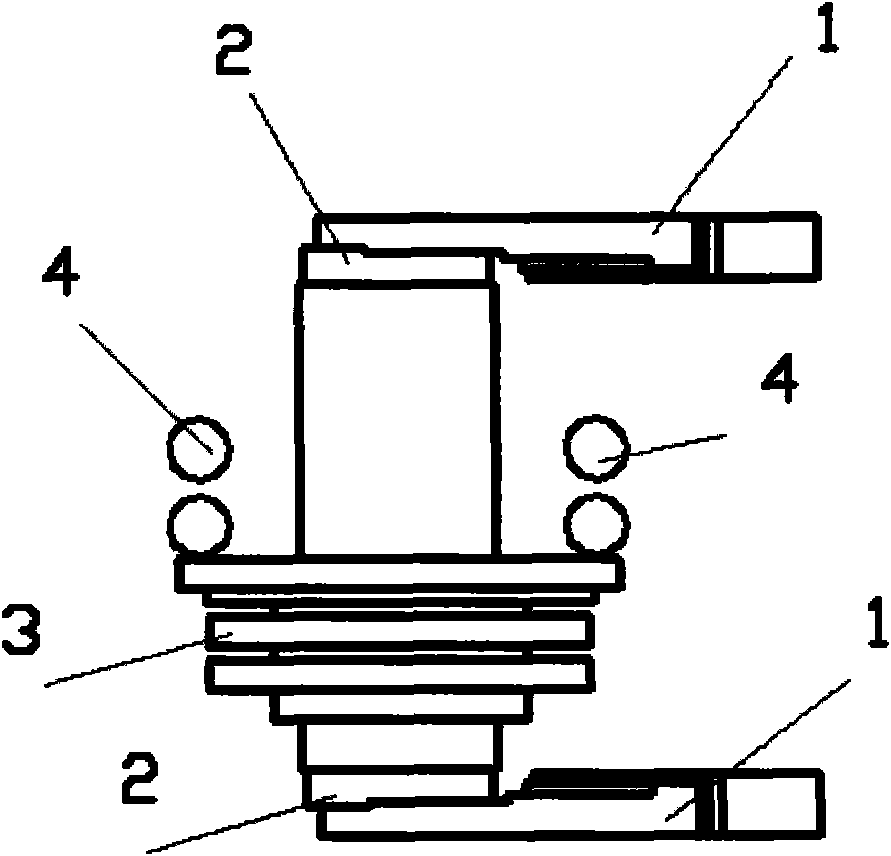

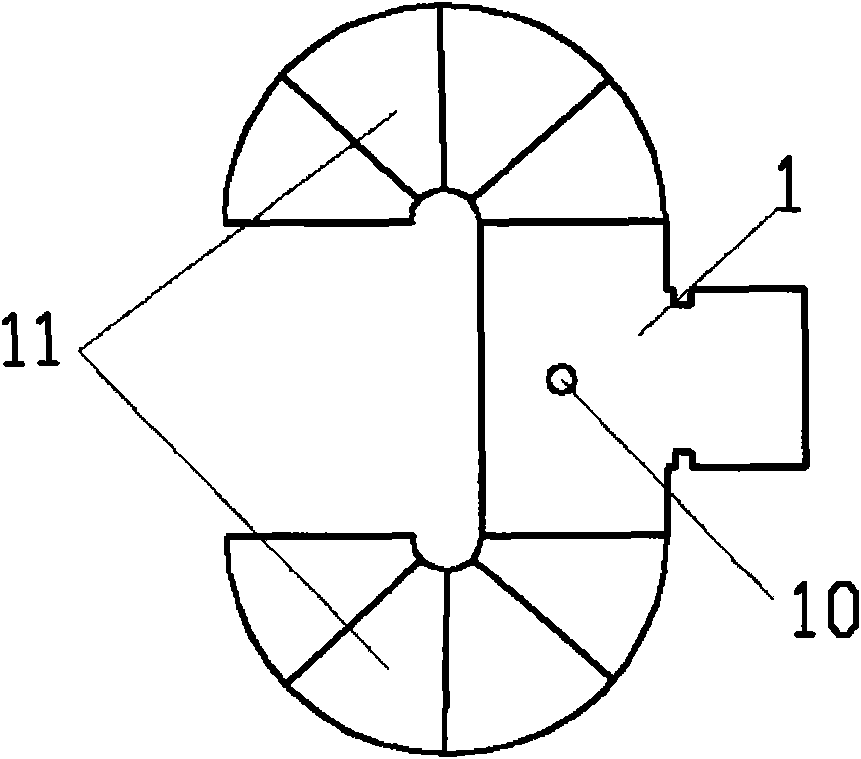

[0029] As attached figure 2 As shown, the rotary joint of the present invention is divided into an upper half and a lower half that are connected to each other. The upper and lower half are respectively formed by connecting an H-face T-shaped branch 1 and a TM01 mode conversion part 2; TM01 mode The conversion part 2 includes a rectangular straight waveguide 20 and a circular waveguide 21, such as Figure 4 As shown, the circular waveguide 21 is butted with the broad side of the rectangular straight waveguide 20; Figure 7 As shown, in the top view of the TM01 mode conversion part 2, the rectangular straight waveguide 20 is symmetrical with respect to the circular waveguide 21, and the two branch ports of the H-plane T-shaped branch 1 are respectively connected to the two ports of the rectangular straight waveguide 20.

[0030] The upper and lower parts of the rotary joint are connected with the bearing 4 through the choke groove 3.

[0031] Such as image 3 As shown, the H-face T-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com