Lithium-ion secondary battery and manufacturing method thereof

A secondary battery and manufacturing method technology, applied in secondary battery, electrolyte storage battery manufacturing, final product manufacturing, etc., can solve the problem of not being able to make full use of supplementary lithium, etc., and achieve the goal of reducing irreversible capacity, improving cycle characteristics, and high reversible capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

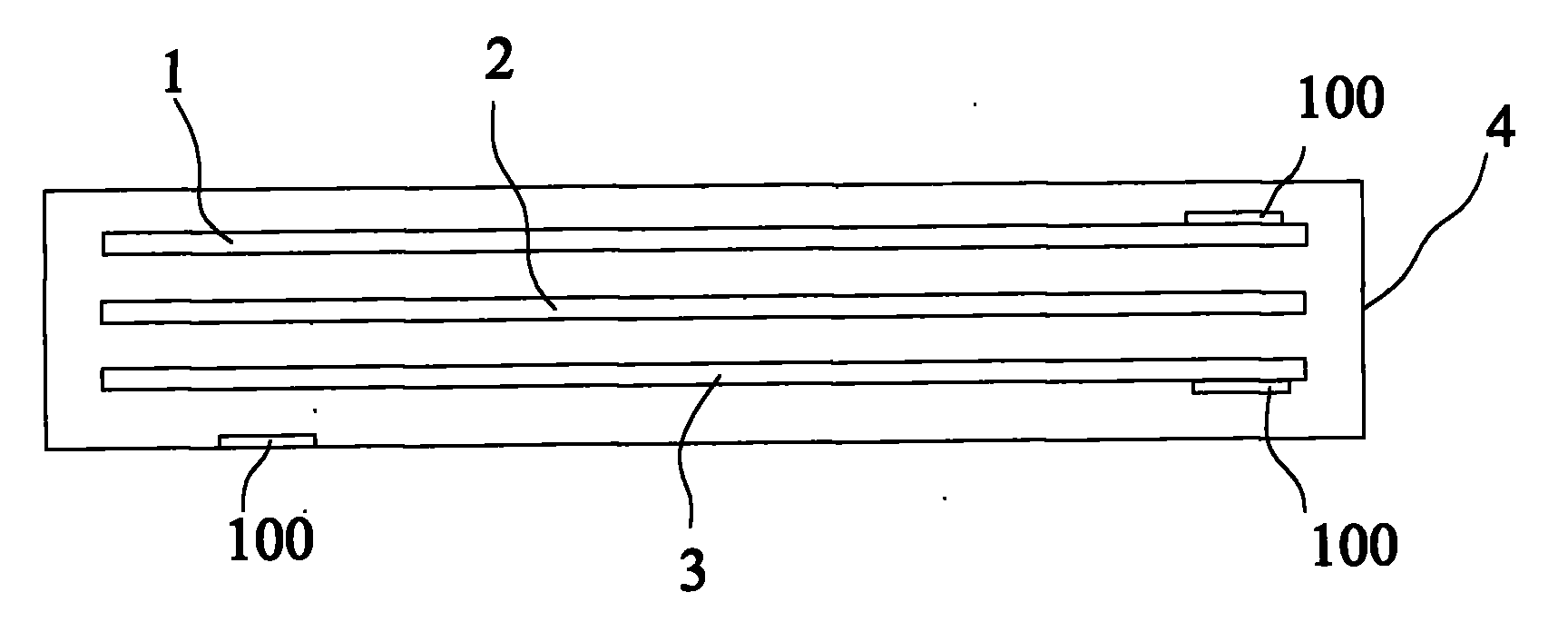

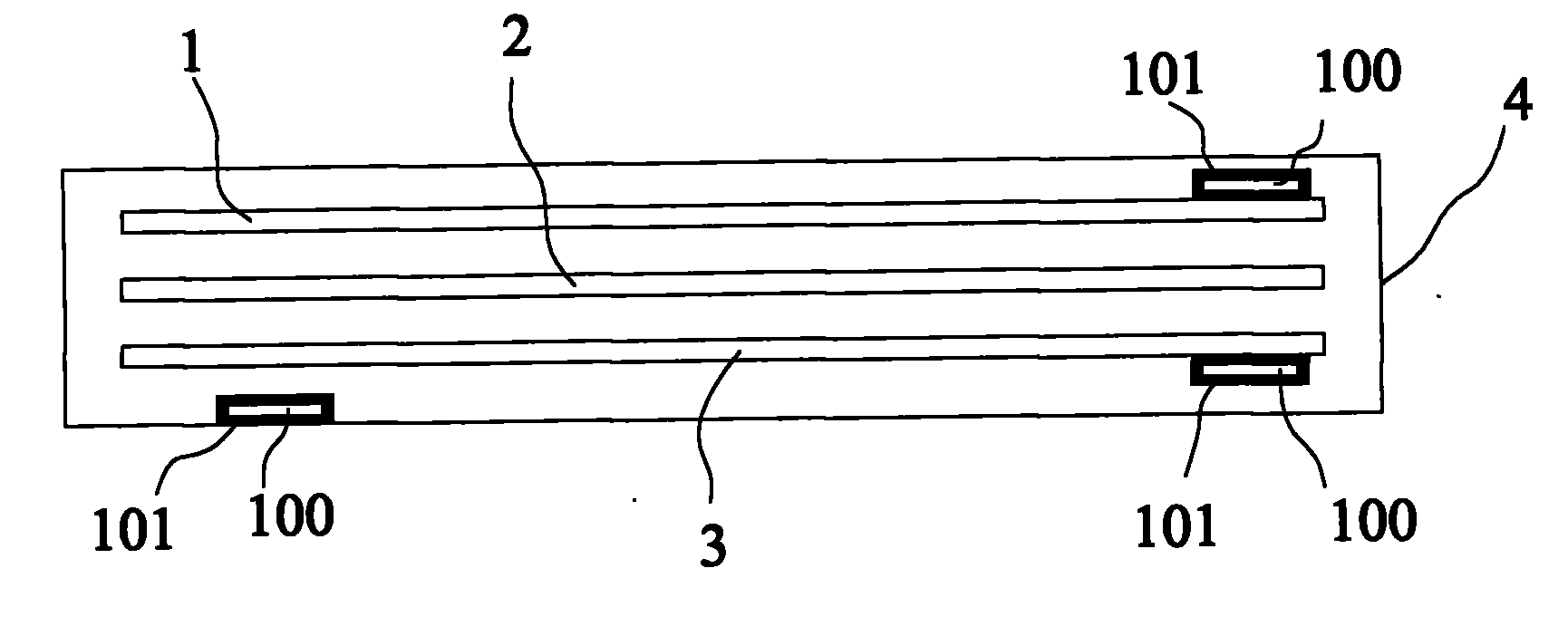

[0031] This example intends to describe in detail the lithium-ion secondary battery disclosed by the present invention, including a pole core, an electrolyte, and a metal casing, and the pole core and the electrolyte are accommodated in the metal casing;

[0032] The pole core includes a positive electrode sheet, a negative electrode sheet, and a separator between the positive electrode sheet and the negative electrode sheet; the positive electrode sheet includes a positive electrode collector and a positive electrode slurry coated on the positive electrode collector, and the negative electrode sheet includes a negative electrode collector and is coated on the negative electrode. Negative electrode slurry on the current collector;

[0033] Among them, a composite lithium sheet is also included, and the composite lithium sheet is arranged in the metal shell;

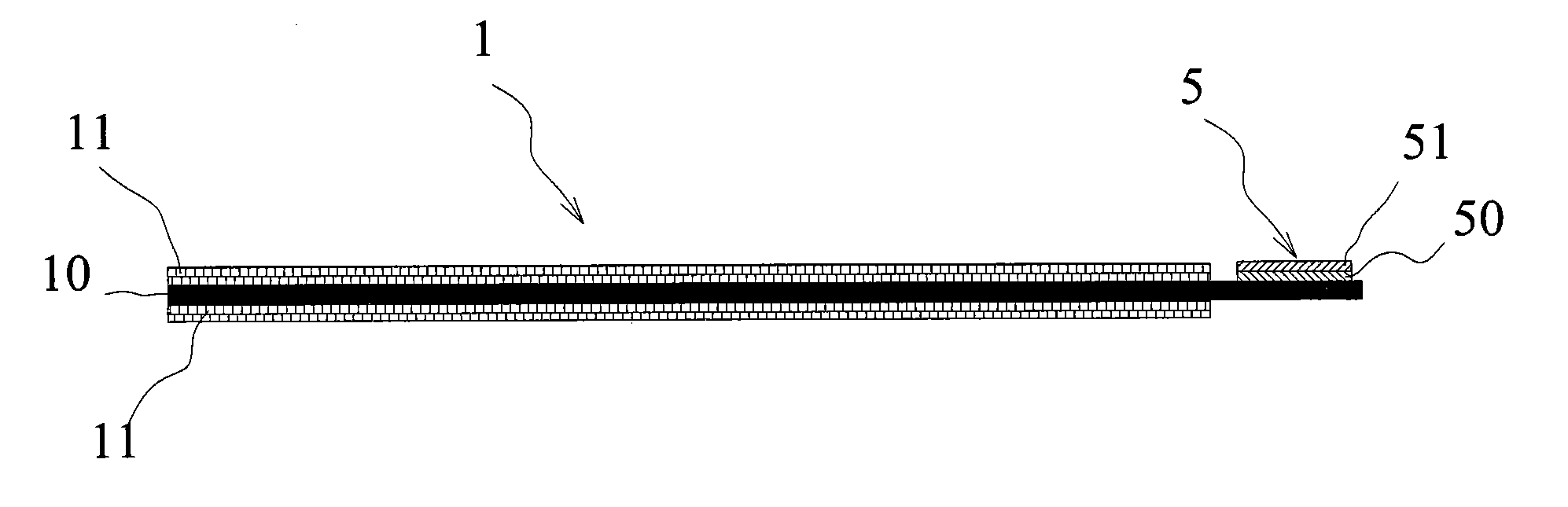

[0034] Such as Figure 7 As shown, the composite lithium sheet 5 includes a metal matrix layer 50 and a lithium coatin...

Embodiment 2

[0063] This example is intended to explain its manufacturing method.

[0064] A method for manufacturing a lithium-ion secondary battery, comprising the steps of:

[0065] Preparation of pole core: Coating the positive electrode slurry on the positive electrode current collector to make the positive electrode sheet, coating the negative electrode slurry on the negative electrode current collector to make the negative electrode sheet, and then setting a separator between the positive electrode sheet and the negative electrode sheet to make the electrode core ;

[0066] Encapsulation: Put the pole core into the metal case, and then inject electrolyte into it;

[0067] In addition, the following steps are also included:

[0068] Making a composite lithium sheet: forming a lithium-coated layer on a metal matrix layer to obtain a composite lithium sheet;

[0069] Welding: welding the metal matrix layer of the lithium composite sheet to the positive electrode current collector or...

Embodiment 3

[0077] 1) Form a uniform slurry with an appropriate amount of positive electrode active materials lithium cobaltate, PVDF, NMP and conductive carbon black, and evenly coat it on the surface of aluminum foil (0.018mm), dry and press it and cut it into a length of 534*width and 43.5*thickness 0.130mm positive plate;

[0078] 2) Fully mix an appropriate amount of negative electrode active material graphite, SBR, conductive carbon black and deionized water to make a slurry, evenly coat the surface of copper foil (0.010mm), dry and press and cut into 554*width 44.5 *Thickness 0.110mm pole piece; reserve 3~5mm at the end of the pole piece without material, which is the welding area with the composite lithium piece;

[0079] 3) Select the positive electrode sheet of the same weight, separate the positive and negative electrodes with a PP separator, and wind them into a pole core;

[0080]4) The composite lithium sheet is coated with lithium on one side. The thickness of the copper f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com