Dustproof film assembly and framework thereof

A technology of dust-proof film components and frames, which is applied in the fields of electrical components, components for photomechanical processing, semiconductor/solid-state device manufacturing, etc., and can solve problems such as high price, poor processability, and increased cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0100] Hereinafter, the present invention will be specifically illustrated and described based on examples, but the present invention is not limited thereto.

[0101] (Example)

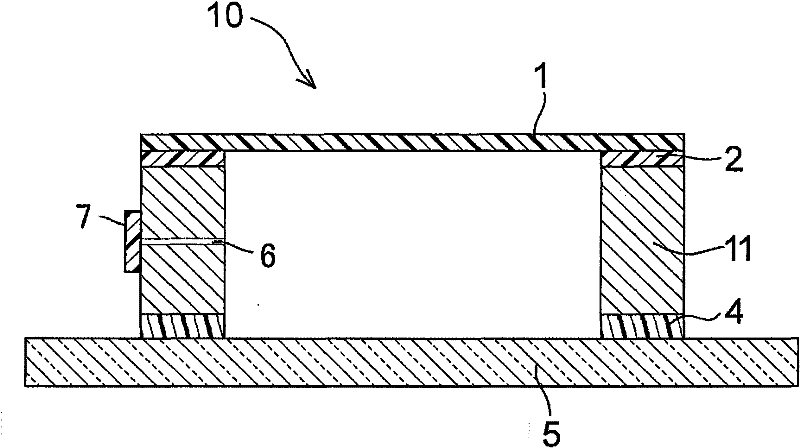

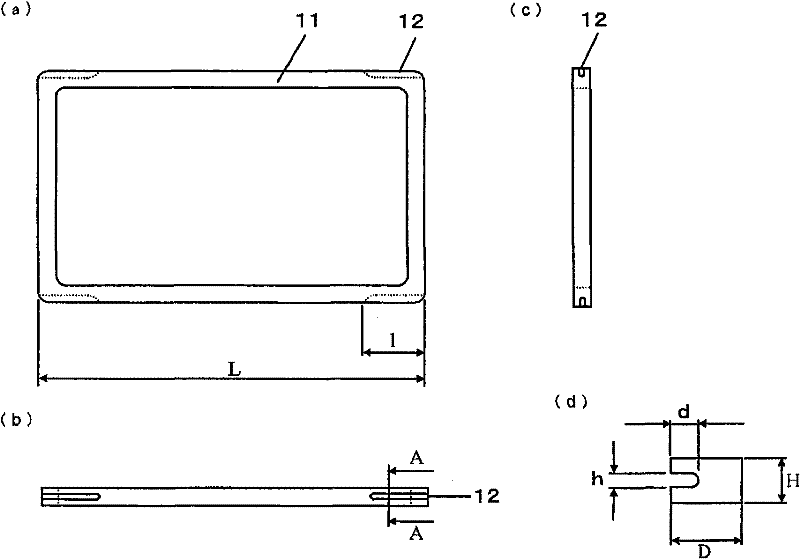

[0102] produced by machining figure 2 The aluminum alloy pellicle frame 11 of the shape shown is shown. The shape of this pellicle frame 11 is that the outer size of each corner is 1068mm × 1526mm, the inner size of the same part is a rectangle of 1031mm × 1490mm, and the thickness H is 6.2mm. The size of each corner is R2 on the inside and R2 on the outside. R6. Here, on both ends of the long sides, such as figure 2 (a)~ figure 2 As shown in (d), the concave portion 12 having a width h=2.4 mm, a depth d=4.0 mm, and a radius of the deepest part of 1.2 mm is provided along the length l=65 mm.

[0103] After the pellicle frame 11 was cleaned and dried, a silicone adhesive was applied as a pellicle adhesive on one end surface, and a silicone adhesive manufactured by Shin-Etsu Chemical Co., Ltd. w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com