Multilayer strand cord twisting process and core wire straightener

A process and cord technology, which is applied to auxiliary devices for rope making, textiles and papermaking, textile cables, etc., can solve the problems of unbalanced stress of inner and outer layers of cords, affecting the performance and life of tires, and uneven film. To achieve the effect of being conducive to promotion and implementation, easy to control and adjust, and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

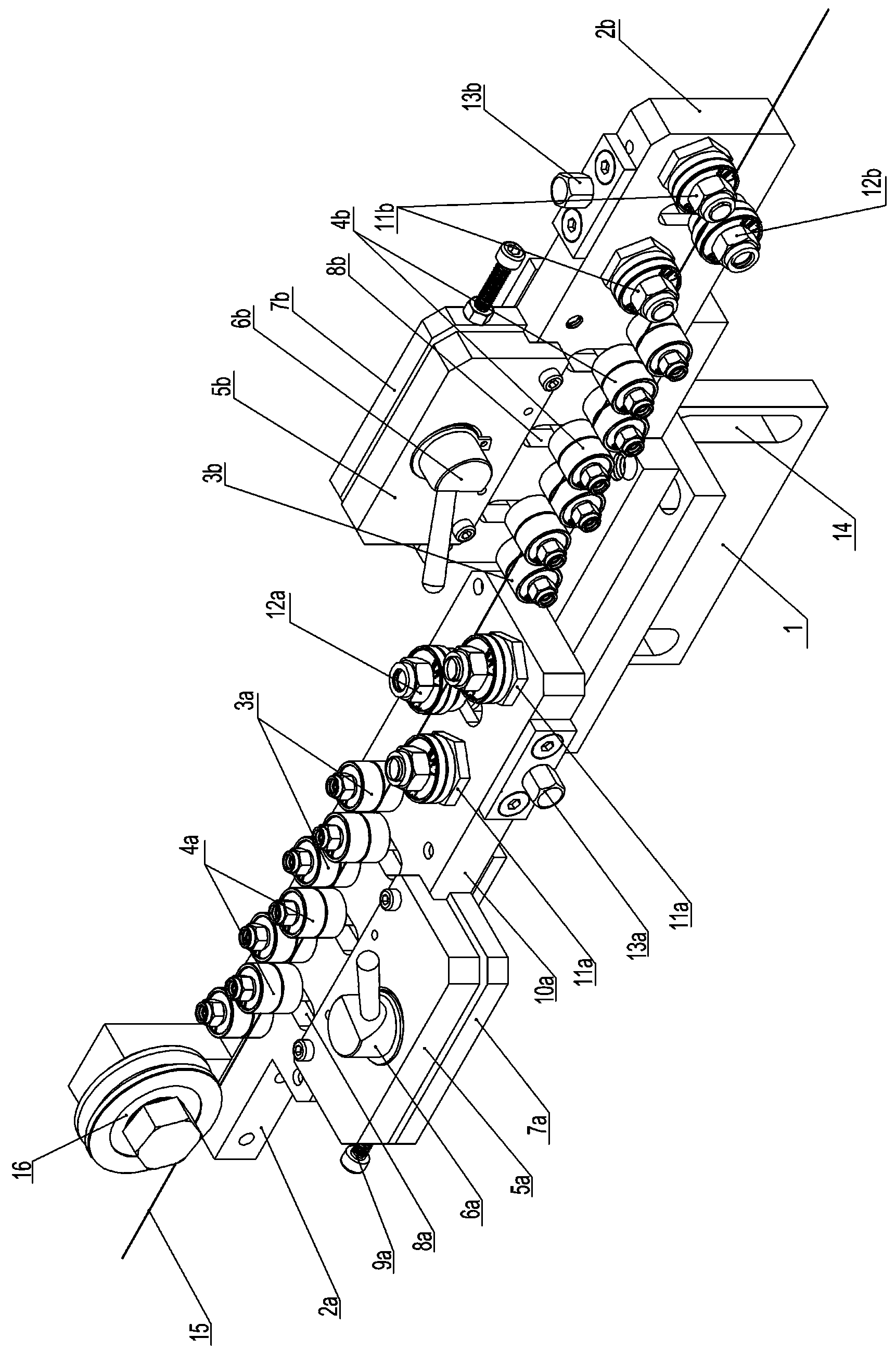

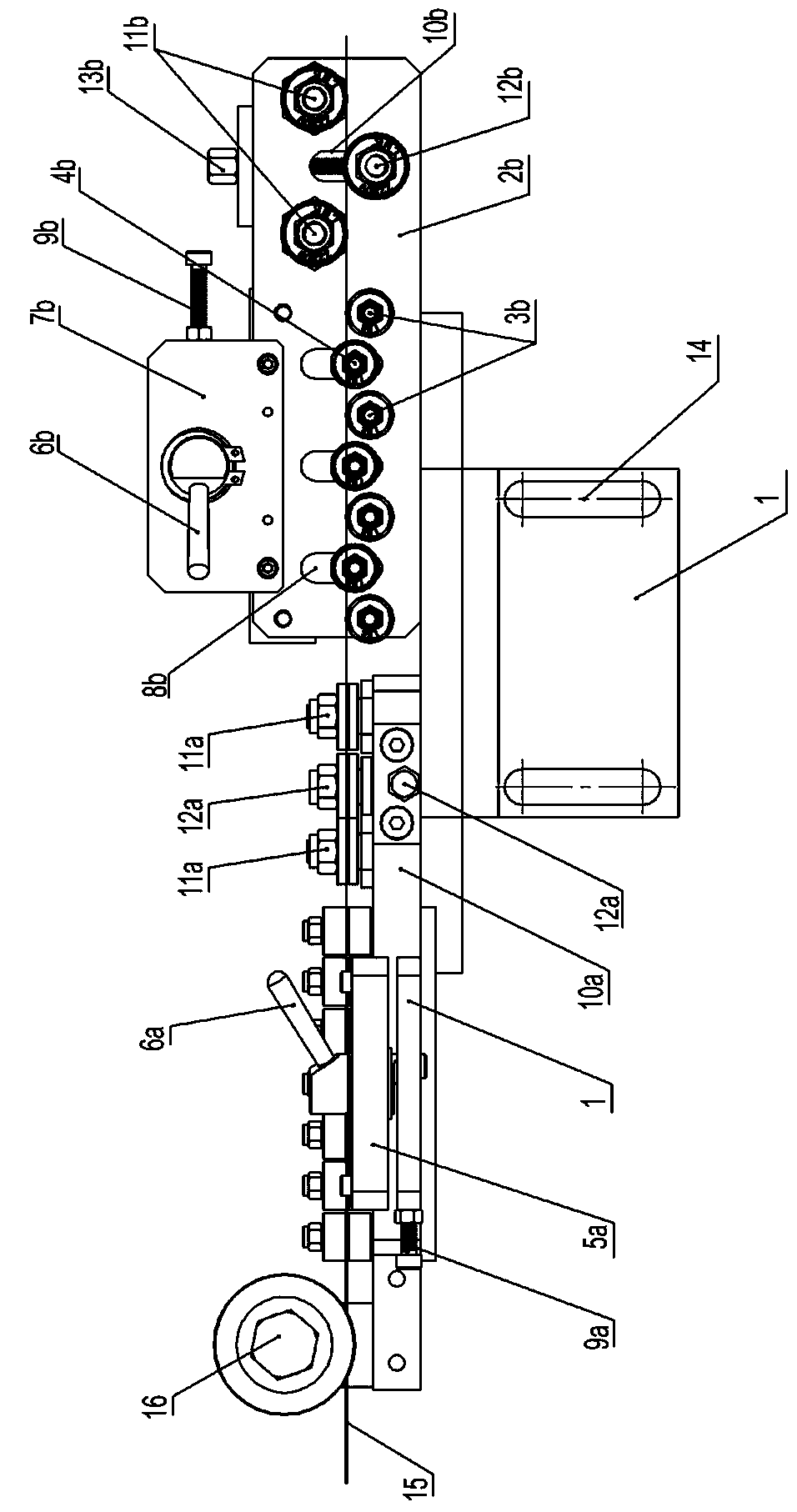

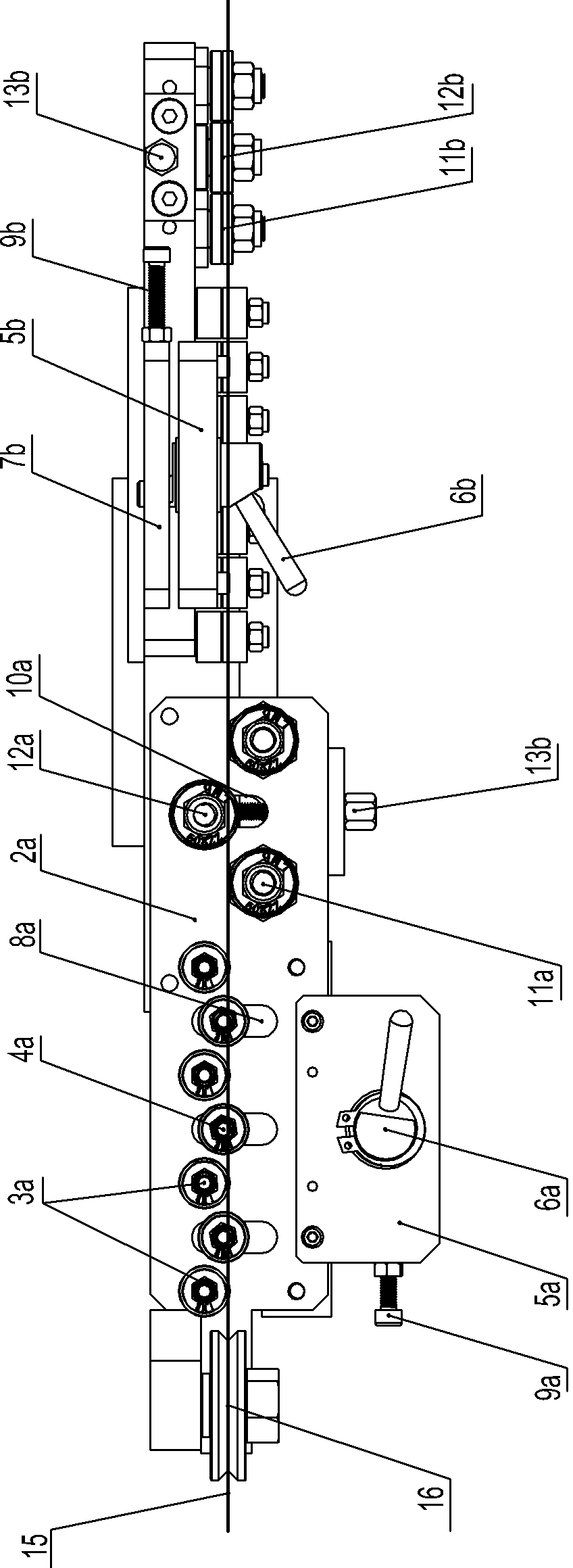

[0028] Embodiment one: see figure 1 , figure 2 , image 3 , this embodiment is a core wire straightener for multi-layer cord twisting, number 1 in the figure is a bracket, 2a, 2b are respectively a horizontally adjustable rolling mechanism and a vertically adjustable rolling mechanism, 3a, 3b are respectively are horizontal fixed pulley and vertical fixed pulley, 4a and 4b are horizontal movable pulley and vertical movable pulley respectively, 5a and 5b are horizontal and vertical adjustment mechanisms respectively, 6a and 6b are horizontal and vertical adjustment knobs respectively, 7a and 7b are respectively 8a and 8b are horizontal and vertical slots respectively, 9a and 9b are internal adjustment screws respectively, 10a and 10b are auxiliary horizontal and auxiliary vertical adjustable rolling mechanisms respectively, 11a, 11b are the fixed pulleys of the horizontal and vertical auxiliary adjustable rolling mechanism, 12a, 12b are the movable pulleys of the horizontal...

Embodiment 2

[0033] Embodiment 2: The drawings are not drawn, and the content is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that the horizontally adjustable rolling mechanism and the vertically adjustable rolling mechanism respectively include a base, and the base can be Translate and fix horizontally and vertically on the bracket, and the horizontal strip-shaped holes and vertical strip-shaped holes are respectively arranged on the corresponding bases.

Embodiment 3

[0034] Embodiment 3: The accompanying drawings are not drawn, and the content is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that the adjusting mechanism is a worm gear, a worm gear matching mechanism or a bevel gear matching mechanism, specifically, on the bracket , and the bottom are fixed and positioned separately to form a sandwich structure. The slide is located in the sandwich mechanism. A worm that can rotate and drag its movement is installed on the slide. A turbine is installed on the positioning plate of the sandwich and directly or on the turbine shaft. Indirect knob or lever.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com