Cr-Fe powder ore cold-hardened pellet binder and process for pelleting by using same

A technology of cold-setting pellets and binders, which is applied in the field of binders, can solve the problems of organic binders burning out, pellets losing strength, and high material surface temperature, and achieve the elimination of crushing and powdering, comprehensive The effect of cost reduction and smelting output increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

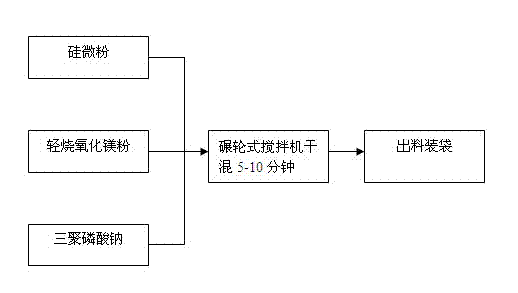

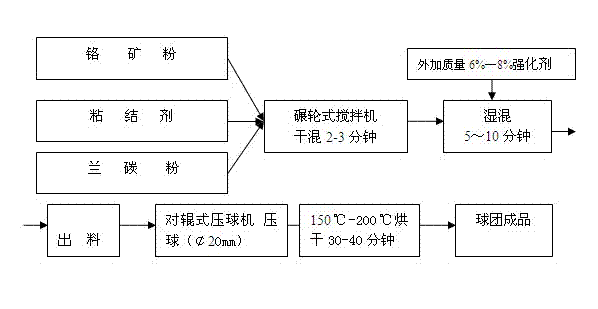

[0024] Embodiment 1, a kind of novel chromite fine ore cold-setting pellet binder, its each component and weight are respectively: silicon micropowder 29kg, lightly burnt magnesia powder 12kg, sodium tripolyphosphate 0.08kg; The three materials are mixed vigorously in a roller mixer to make a uniform mixture; using the process of making pellets with the binder, 20kg of the binder is used, mixed with 213kg of South African ferrochrome powder, Shenmulan carbon 13.3 kg of powder, after 2-3 minutes of dry mixing on the roller mixer, 20kg of strengthening agent, continue to stir vigorously for 10 minutes, then discharge, and press it into pellets with a diameter of 20mm through a double-roller briquetting machine. Wet pellet strength ≥ 4 times (the average number of times 10 pellets fall on the steel plate at a height of 0.5m without breaking), dry pellet strength ≥ 8 times (10 pellets fall on the steel plate from a height of 1 meter, and the number of unbroken average times). Aft...

Embodiment 2

[0025] Embodiment 2, a new type of chromite powder ore cold-setting pellet binder, its components and weight are respectively: 27.5 kg of silicon micropowder, 9 kg of lightly burned magnesium oxide powder, and 0.07 kg of sodium tripolyphosphate; Said three kinds of materials are made into homogeneously mixed materials through vigorous stirring in a roller mixer; using the process of making pellets with said binder, 20 kg of said binder is taken, mixed with 110 kg of South African ferrochrome fine ore, 110 kg of Brazilian ferrochrome powder, 16 kg of Shenmulan carbon powder, dry mixed in a roller mixer for 2-3 minutes, added 20kg of strengthening agent, continued to stir vigorously for 10 minutes, and the material was discharged to a roller briquetting machine, and pressed into Pellets with a diameter of 20mm. Wet bulb drop strength of 0.5 meters ≥ 5 times; after drying at 180 ℃, wind speed 1.0m / s ~ 1.8m / s, 30 minutes, 1 meter drop strength ≥ 15 times. When heated at 1000°C, t...

example 3

[0026]Example 3, a novel chromite powder ore cold-setting pellet binder, its components and weight are respectively: 32 kg of silicon micropowder, 8 kg of lightly burned magnesia powder, and 0.08 kg of sodium tripolyphosphate; The three kinds of materials are stirred vigorously in a roller mixer to make a homogeneously mixed material; using the process of pelletizing the binder, 28kg of the binder is used, and 170kg of South African ferrochrome powder is mixed with Madagascar. 170 kg of Si chromite powder ore, 20 kg of Shenmulan charcoal powder, dry mixed in a roller mixer for 2-3 minutes, 30 kg of strengthening agent, continue to stir vigorously for 10 minutes, and the output is pressed by a double-roller ball press into pellets with a diameter of 20 mm. Wet bulb drop strength ≥ 4 times at 0.5 meters; after drying at 180°C, wind speed 1.0m / s~1.8m / s, and 30 minutes, 2m drop strength ≥8 times; Pulverization; 1350 ° C, 2 hours of heating and reduction, the sphere only compresse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com