Styrene-butadiene rubber modified asphalt composition and preparation method thereof

A technology of asphalt composition and styrene-butadiene rubber, which is applied in the direction of building structure, building components, building insulation materials, etc., can solve the problems of slow cross-linking speed, index drop, fast cross-linking speed, etc., to improve the viscosity and toughness and Toughness, product cost reduction, and effect of increasing crosslinking speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

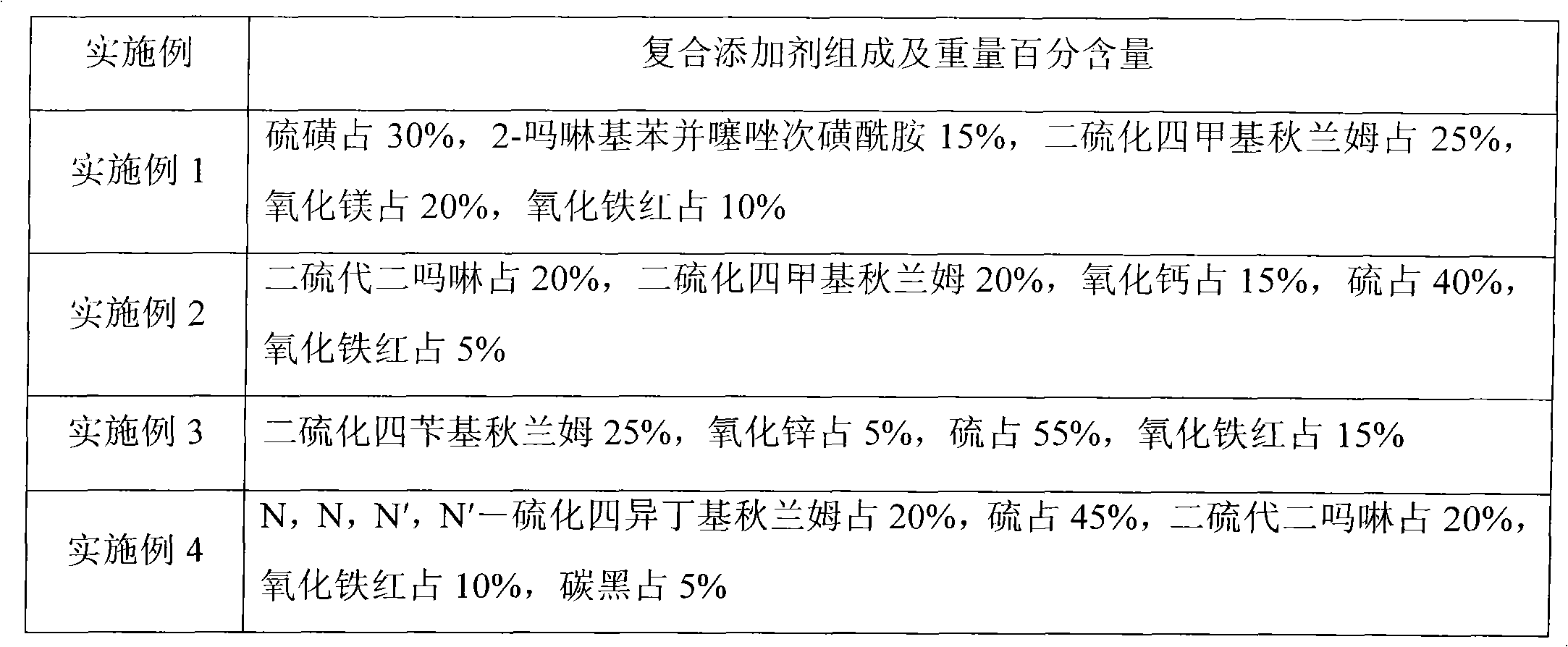

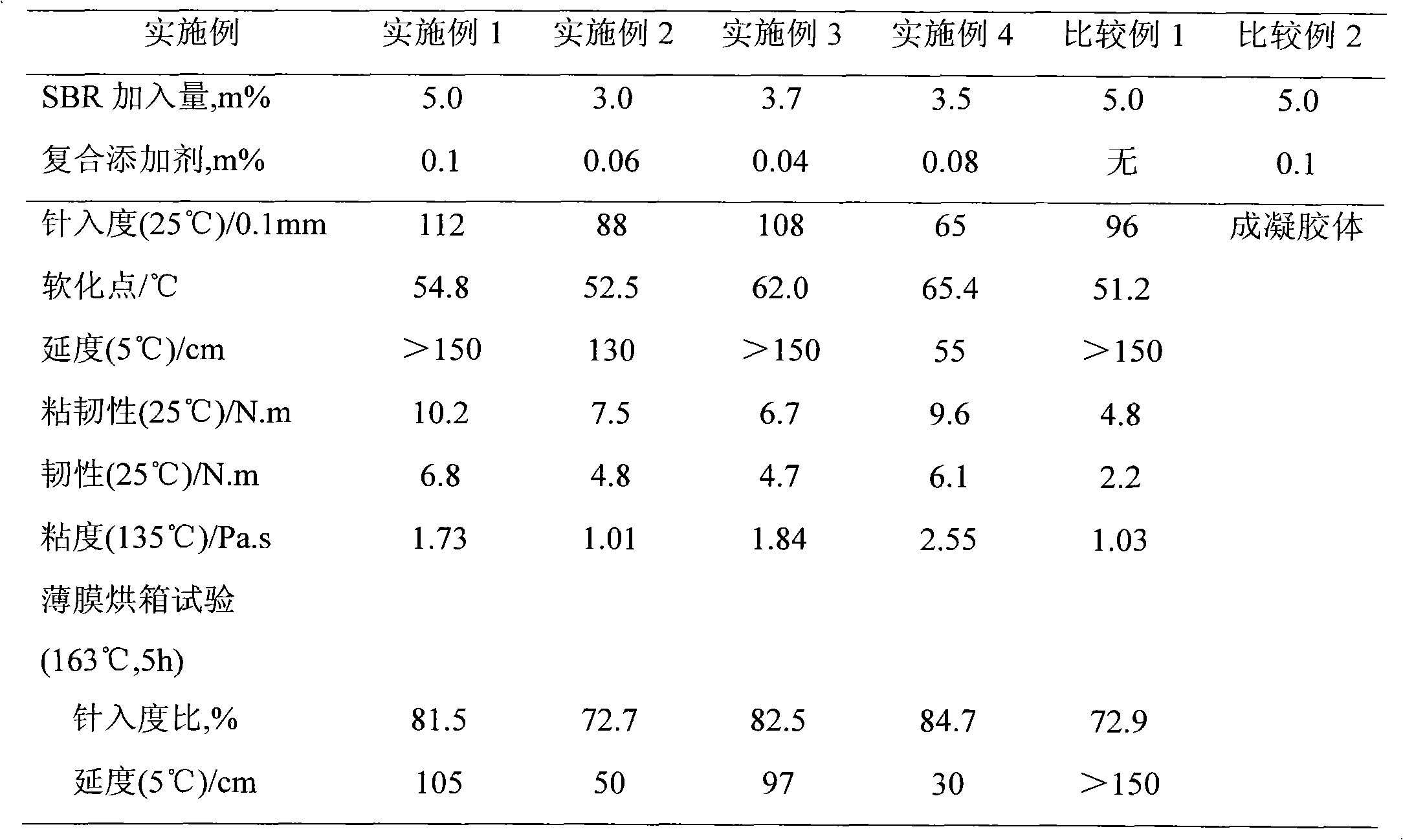

Examples

Embodiment 1

[0033] Heat the base asphalt at 160°C to a molten state, cut the block SBR (type 1500) into small particles below 10mm and add it to the base asphalt. The penetration of the base asphalt at 25°C is 140 1 / 10mm, and the softening point is 40.5°C, accounting for 94.9% (m) of the total amount, and SBR accounting for 5.0% of the total amount. At 160°C, mix with a high-shear emulsifier (rotational speed: 3800r / min) for 20 minutes, and then add it evenly over 40 minutes Composite additives accounting for 0.1% of the modified asphalt, the mixing reaction ended after 180 minutes, and the properties of the modified asphalt were tested (results are shown in Table 2).

Embodiment 2

[0035] Heat the base asphalt to 170°C to melt, and add SBR (type 1502) into the melted base asphalt under stirring with a high-shear mixer emulsifier (speed: 3900r / min). Among them, the 25°C penetration of the base asphalt is 128 1 / 10mm, the softening point is 43.6°C, accounting for 96.44% (m) of the total modified asphalt, and the powder SBR accounts for 3.0% of the total. At 170°C, mix for 50 minutes, and then use a common paddle stirring device (rotating speed 400r / min) to stir. At 170°C, add 0.06% of the total amount of composite additives into the above mixture in two batches, each batch The time for adding is 10 minutes, added in 5 times, the interval between two batches of adding is 50 minutes, and the reaction is completed after keeping 170°C for 150 minutes, and the properties of the modified asphalt are tested (results are shown in Table 2).

Embodiment 3

[0037] Heat the base asphalt to 180°C to melt, and add powdered SBR (type 1712) into the melted base asphalt under stirring with a high-shear emulsifier (rotational speed: 4000r / min). Among them, the 25°C penetration of base asphalt is 109 1 / 10mm, the softening point is 44.6°C, accounting for 96.26% (m) of the total modified asphalt, and the powder SBR accounts for 3.7% of the total. At 180°C, shear and mix for 30min, then switch to a common paddle stirring device (rotating speed 300r / min), and add 0.04% of the total amount of composite additives in three batches at 180°C, the first batch accounts for 30% of the composite additives 50%, add with 15min, after 30min, add the second batch of composite additive (accounting for 30% of composite additive), add with 5min, after 30min, add the 3rd batch of composite additive (account for 20% of composite additive), use After 10 minutes of adding, the mixing reaction ended after 120 minutes, and the properties of the modified asphalt w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com