Aryl silicate ester flame retardant plasticizer and preparation method thereof

A technology of flame retardant plasticizer and aryl silicate, which is applied in the direction of silicon organic compounds, can solve problems such as processing problems that limit the development of polysilicon industry, unsynchronized development, waste of resources and the environment, and achieve good application prospects. Good solubility and plasticity, good thermal stability, high flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

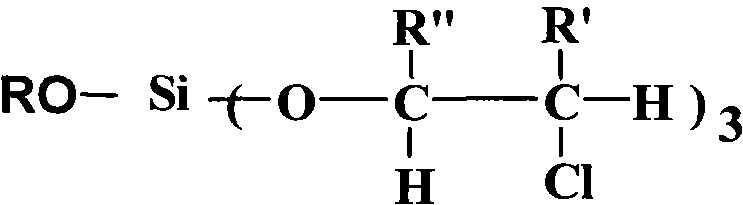

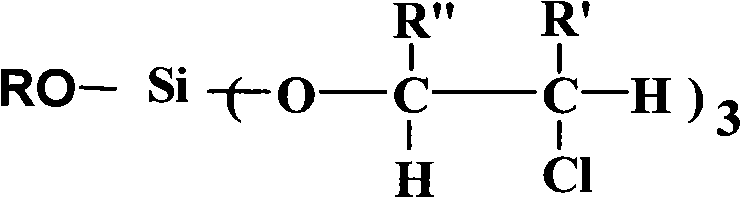

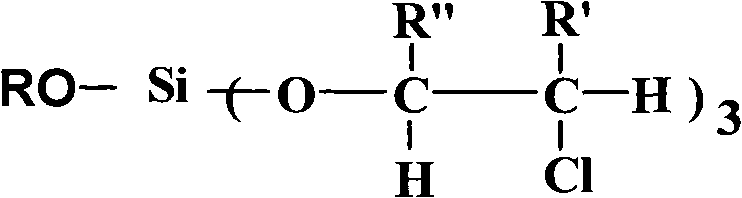

Method used

Image

Examples

preparation example 1

[0020] Preparation Example 1 In a 150ml four-necked bottle equipped with a stirrer, a thermometer, a high-efficiency reflux condenser and a hydrogen chloride absorption device connected to the upper mouth of the condenser, nitrogen protection was introduced, 0.1mol of silicon tetrachloride was added, and the liquid was started at 20°C. Add 0.1mol benzyl alcohol dropwise under the surface, and the reaction will release hydrogen chloride. After the hydrogen chloride is released, replace the upper port of the condenser tube with an extremely flexible and expandable soft seal, stir, and start to introduce 0.3mol epoxy under the liquid surface at 20°C. Ethane was cooled in an ice-water bath, and the temperature was controlled at the rate of introduction. After the passage, the temperature was maintained at about 20°C for 4 hours, and then the temperature was raised to 40°C for half an hour. Heat and reduce pressure to distill off excess reactants and low boiling point substances and...

preparation example 2

[0021] Preparation Example 2 In a 150ml four-necked bottle equipped with a stirrer, a thermometer, a high-efficiency reflux condenser and a hydrogen chloride absorption device connected to the upper mouth of the condenser, nitrogen protection was introduced, 0.1mol of silicon tetrachloride was added, and the liquid was started at 20°C. Add 0.1mol of benzyl alcohol dropwise under the surface, and the reaction will release hydrogen chloride. After the hydrogen chloride is released, replace the upper port of the condenser tube with an extremely flexible and expandable soft seal, stir, and start to drop 0.4mol of epoxy under the liquid surface at 20°C. Propane, cooled in an ice-water bath, and the temperature was controlled by the dropping rate. After the dropping, the temperature was maintained at about 20°C for 8 hours, and then the temperature was raised to 40°C for 1 hour. Heat and reduce pressure to distill off excess reactants and low boiling point substances and recycle them...

preparation example 3

[0022] Preparation Example 3 In a 150ml four-necked bottle equipped with a stirrer, a thermometer, a high-efficiency reflux condenser and a hydrogen chloride absorption device connected to the upper mouth of the condenser, nitrogen protection was introduced, 0.1mol of silicon tetrachloride was added, and the liquid was started at 20°C. Add 0.1mol of benzyl alcohol dropwise under the surface, and the reaction will release hydrogen chloride. After the hydrogen chloride is released, add 0.4mol of epichlorohydrin dropwise under the liquid surface (gradually increase the temperature as the reaction progresses), maintain the temperature at about 90°C, and react for another 8 hours Afterwards, excessive reactants and low boiling point substances were distilled off under reduced pressure and recycled for use, and tris(dichloropropyl)benzyl silicate was obtained by filtration, with a yield of 95%, a decomposition temperature of 264±5°C, and a flash point of (open cup) is 231±5°C, the de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Decomposition temperature | aaaaa | aaaaa |

| Decomposition temperature | aaaaa | aaaaa |

| Refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com