Hydrolytic absorption type desulfurizing agent, preparation method and application thereof

A desulfurizer and absorption-type technology, which is applied in the field of hydrolysis and absorption-type desulfurizer and its preparation, can solve the problems of inapplicable treatment and achieve the effect of increasing sulfur capacity and good hydrolysis activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

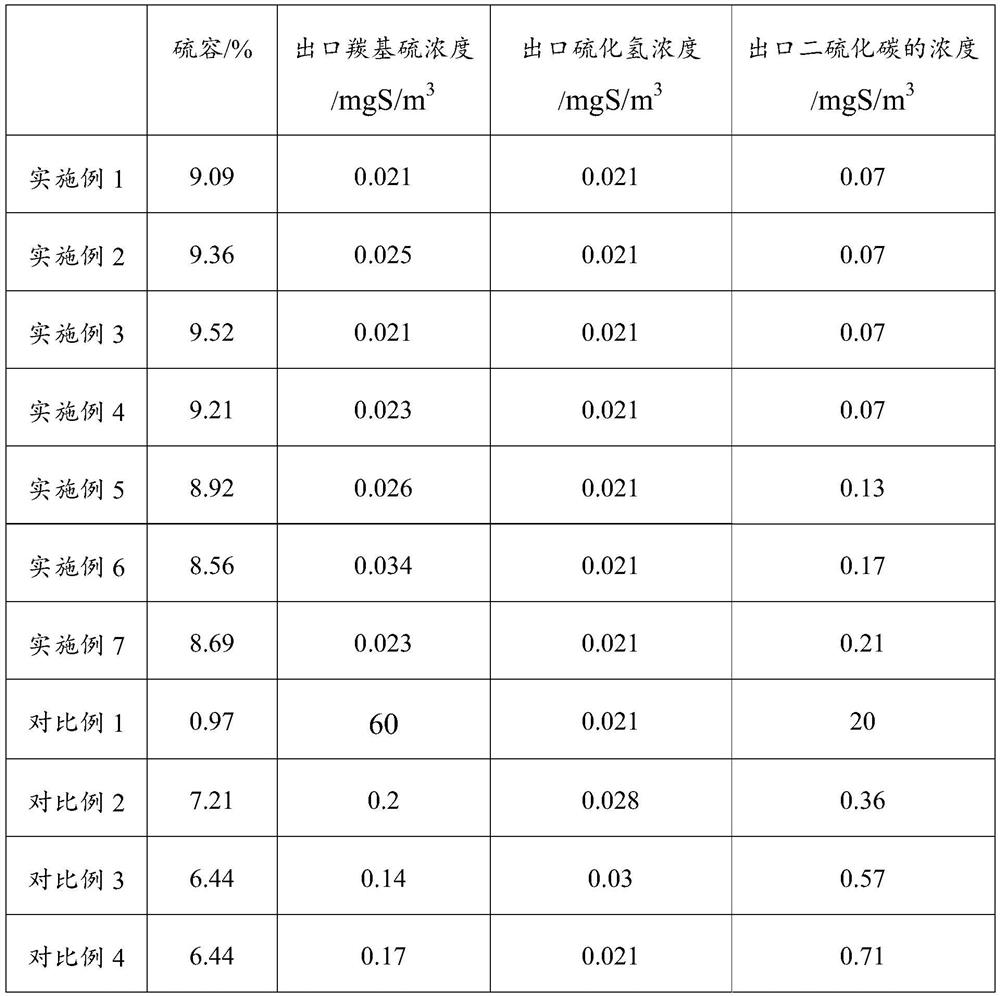

Examples

Embodiment 1

[0028] This embodiment provides a hydrolytic absorption type desulfurizer, the preparation method of which is as follows:

[0029] 287.55g of zinc sulfate heptahydrate and 155.60g of calcium hydroxide were put in the mixer and mixed for 20min, then 77.15g of concentration was added to the potassium hydroxide aqueous solution of 40wt%, and continued to mix in the mixer for 15min, and then the mixer The material in is extruded and dried at 100°C for 6 hours.

Embodiment 2

[0031] This example provides a hydrolytic absorption type desulfurizer, the preparation method of which is as follows:

[0032] After putting 269.54g of zinc sulfate hexahydrate and 148.19g of calcium hydroxide in a kneader and mixing for 30min, adding 58.44g of a concentration of 48wt% potassium hydroxide aqueous solution, continuing to mix in a kneader for 30min, and then mixing the materials in the kneader Extrude and dry at 150°C for 1 hour.

Embodiment 3

[0034] This example provides a hydrolytic absorption type desulfurizer, the preparation method of which is as follows:

[0035] After putting 287.55g of zinc sulfate heptahydrate and 159.31g of calcium hydroxide in the mixing mill and mixing for 50min, adding 67.32g concentration is 50wt% potassium hydroxide aqueous solution, continuing to mix in the mixing mill for 40min, and then the mixing mill The material in is extruded and dried at 120°C for 3 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com