Mechanical and electrical integrated driving wheel system

A driving wheel, electromechanical technology, applied in the direction of wheels, electromechanical devices, electric components, etc., can solve the problems of unsuitable power performance and use environment of medium and heavy vehicles, large driving torque, etc., to improve system integration, high power density, The effect of increasing the driving torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

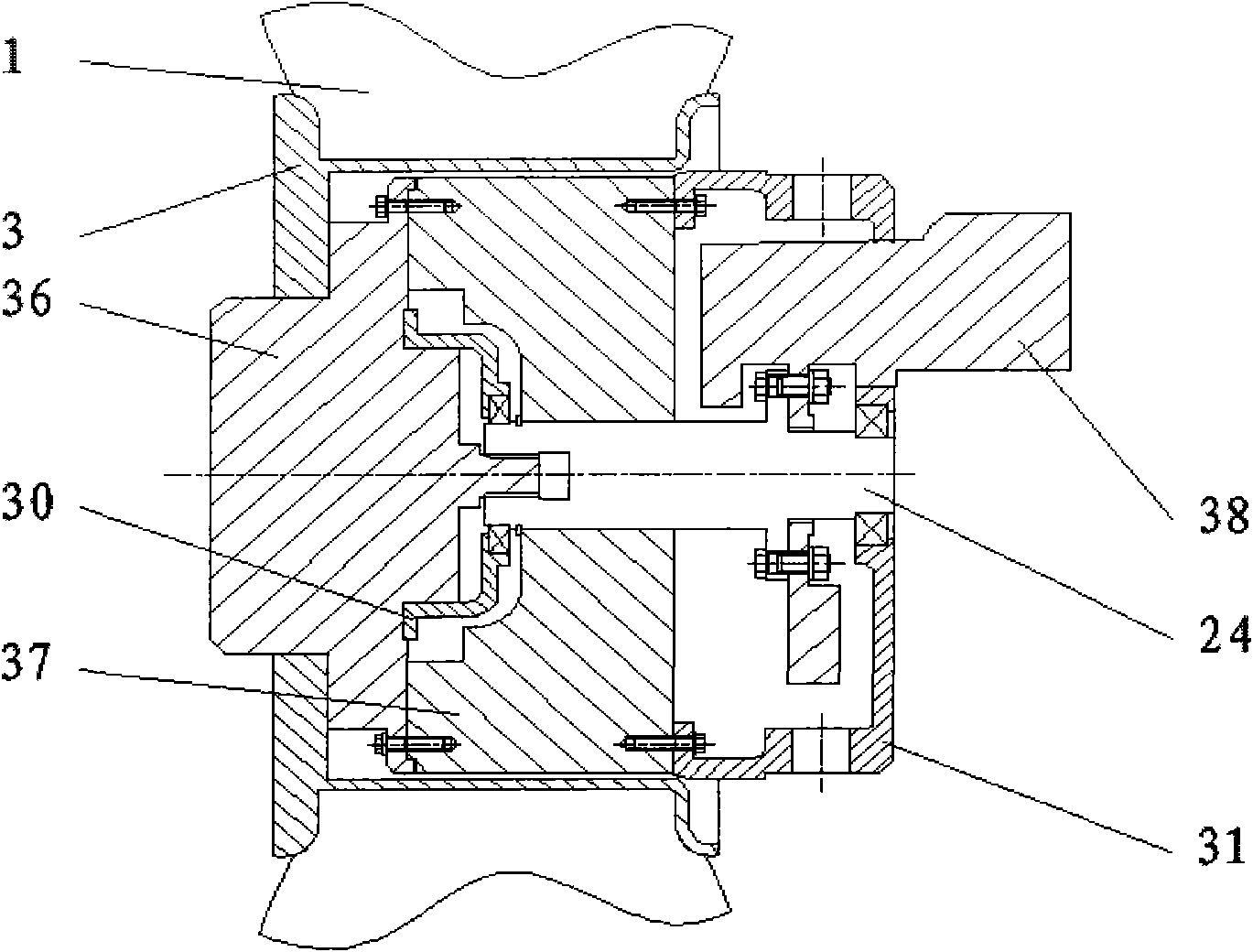

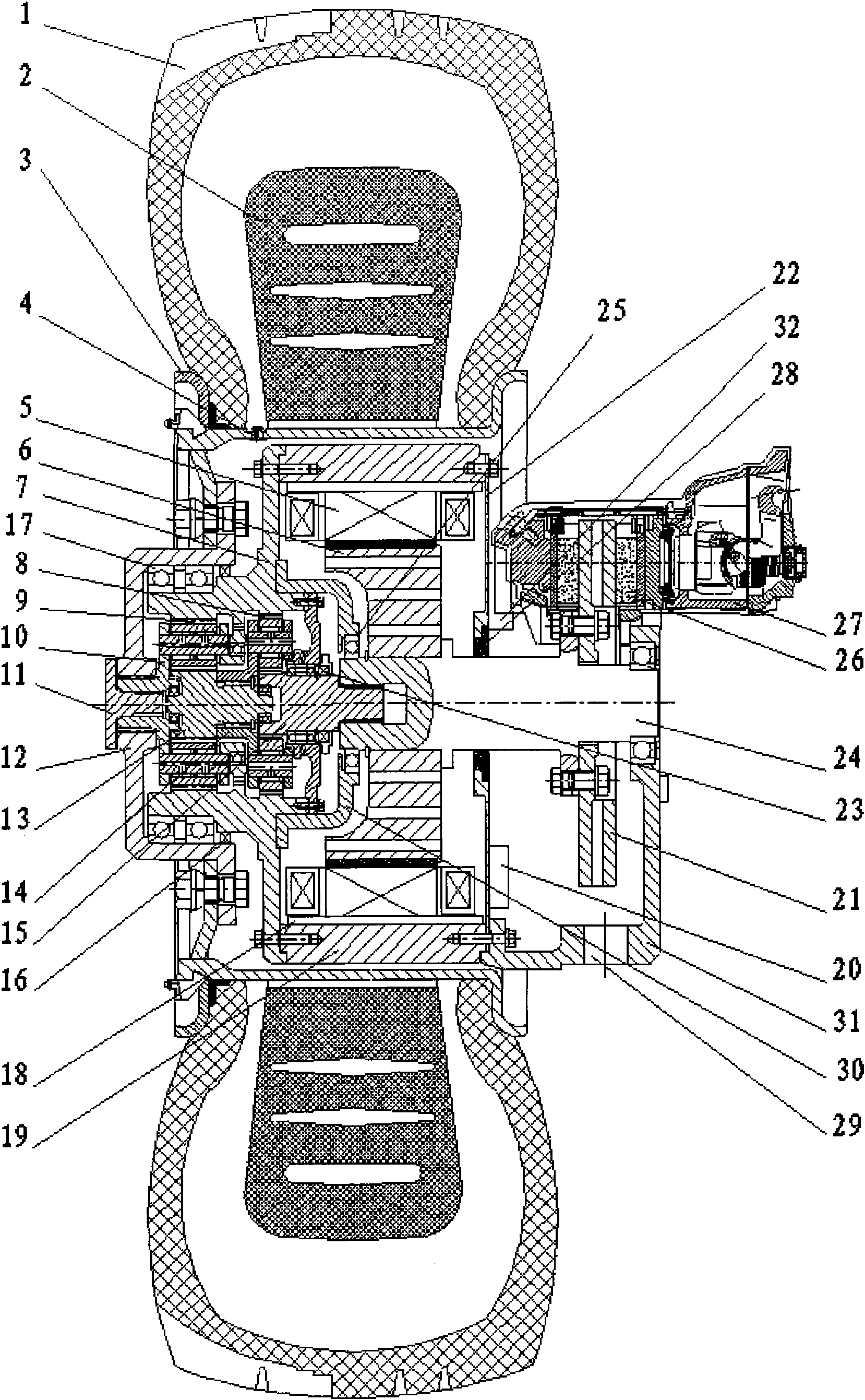

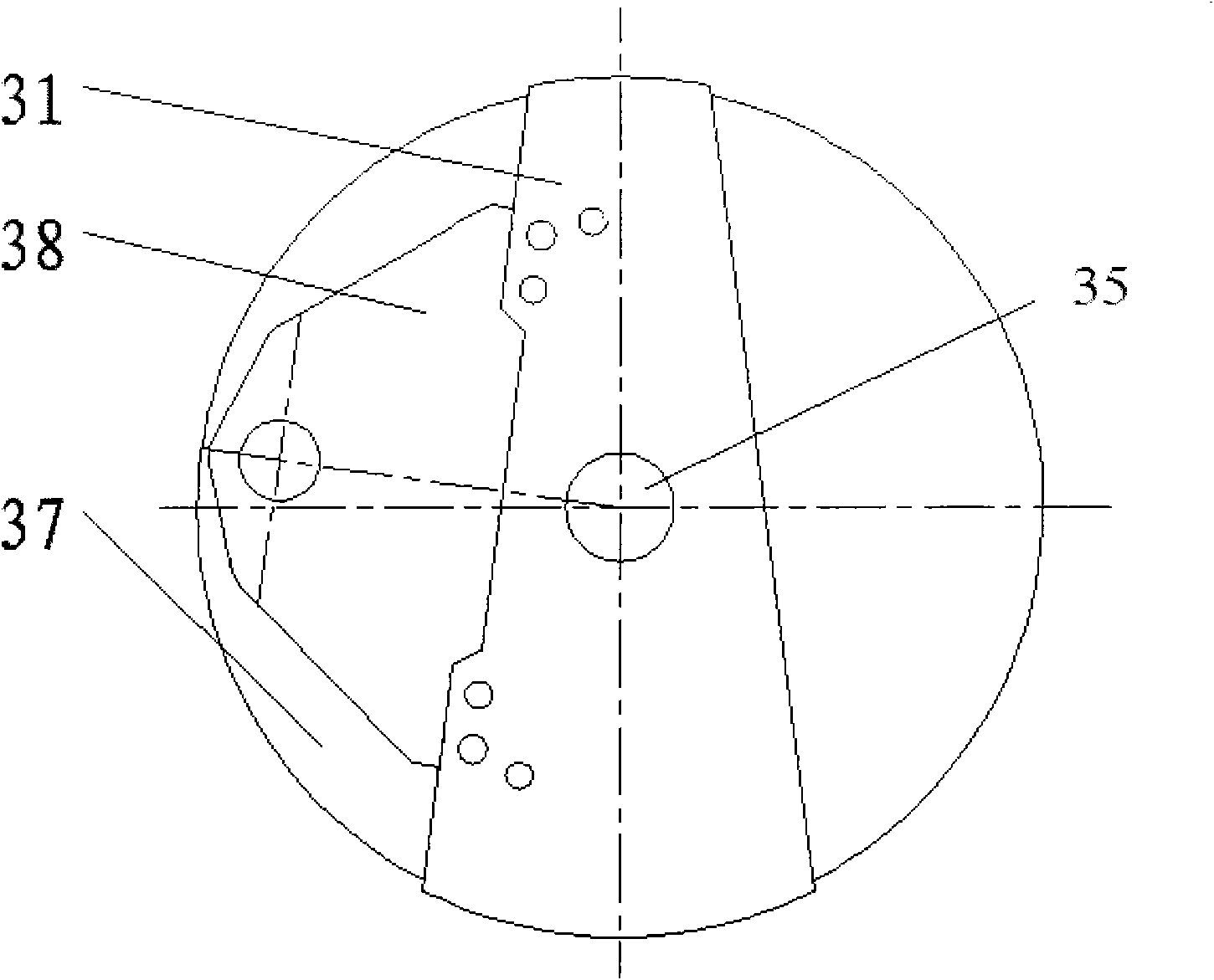

[0022] like figure 2 Shown is a new electromechanical integrated drive wheel system for pneumatic brakes of the invention, which is suitable for brakes with larger diameters and installed on different sides. The new electromechanical integrated driving wheel system includes a tire steel rim 3, tire rubber body 1, transmission main shaft 24 and braking device 38, and the transmission main shaft 24 of the driving wheel is connected with a driving motor system, a deceleration torque increasing system and a braking system. The device 38, and the drive motor device 37 and the deceleration and torque increasing device 36 are all integrated in the tire rim 3. The transmission main shaft 24 of this driving wheel has a cylindrical groove for the left end, has a cylinder structure of keyway in the cylindrical groove, and the middle part of transmission main shaft 24 is fixed with drive motor rotor 6. The motor stator silicon slice and the winding 5 are fixed on the drive motor housing...

Embodiment 2

[0031] This embodiment is suitable for brakes with smaller diameters and installed on the same side. The basic mechanism is similar to that of Embodiment 1, except that the brake device 38 adopts a hydraulic brake, and the installation position is slightly different. Figure 4 shown. In the present invention, the transmission main shaft 24 is the main component, the drive motor rotor 6 is fixed in the middle of the main shaft, the front end of the main shaft is connected with the primary planetary sun gear 15 to drive the sun gear through a spline connection, and the output power of the primary planetary frame 14 is connected with the secondary sun gear 13 connection, output power through the secondary planetary frame 10, and drive the tire steel ring 3 and the tire rubber body 1 to rotate partially. The first-stage planetary ring gear 8 and the second-stage planetary ring gear 9 are fixed in the reducer housing 7 and are fixed parts of the planetary reducer. The reducer hous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com