Automatic polishing machine

An automatic polishing and electric motor technology, which is applied to surface polishing machine tools, grinding/polishing equipment, metal processing equipment, etc., can solve problems such as high labor intensity, difficult and dangerous manual operation, and heavy weight of polishing machines, so as to reduce work intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

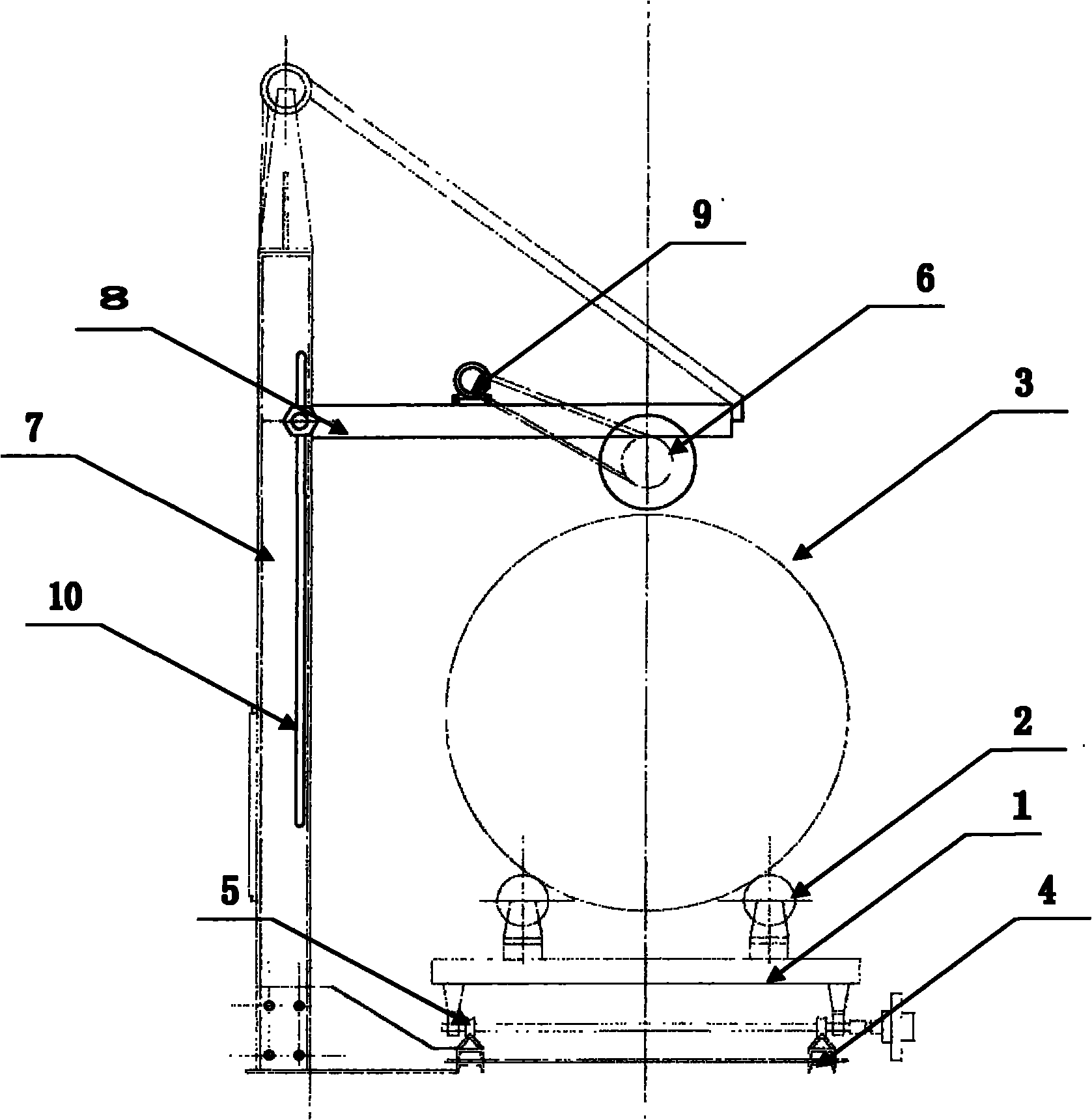

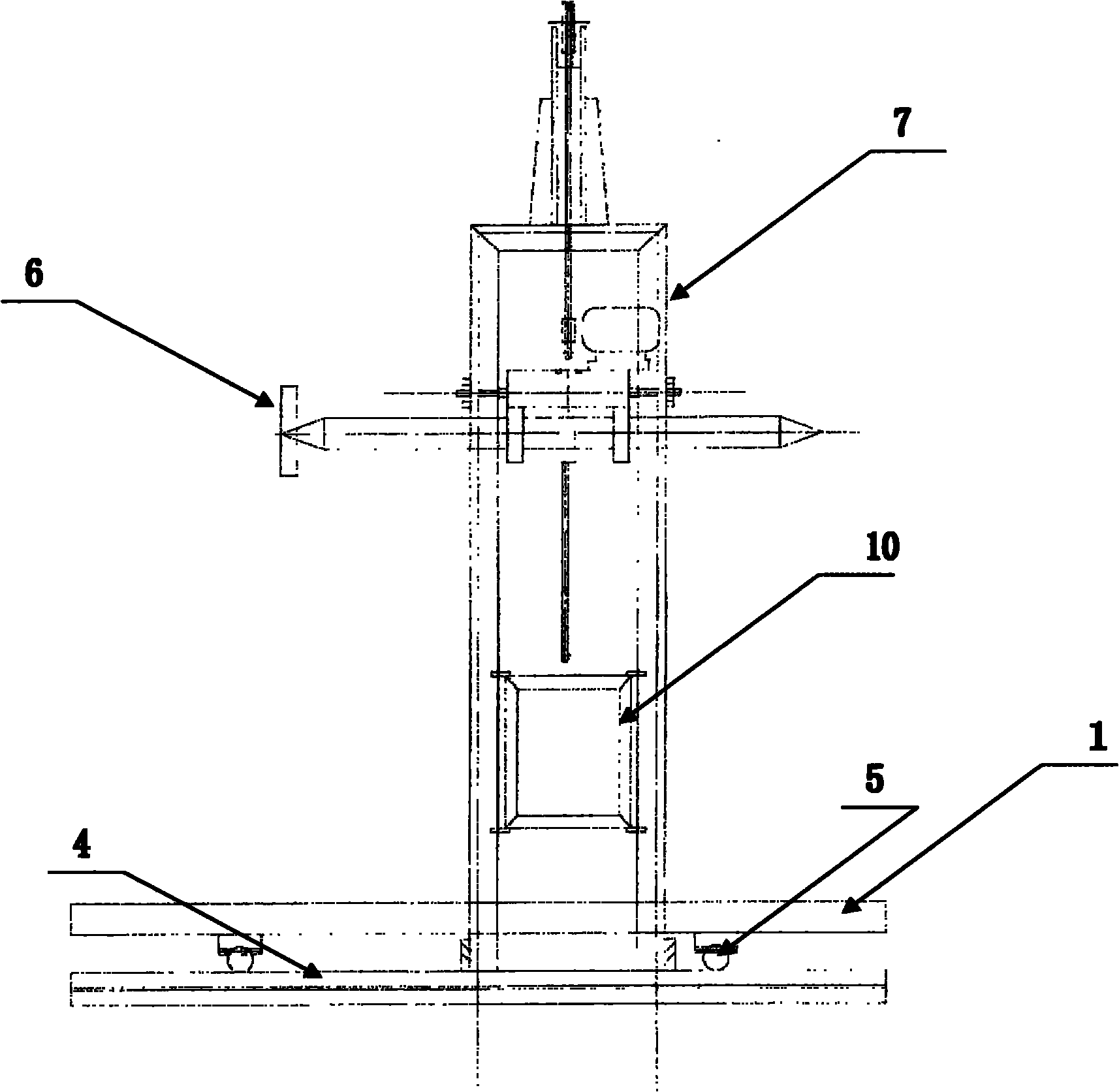

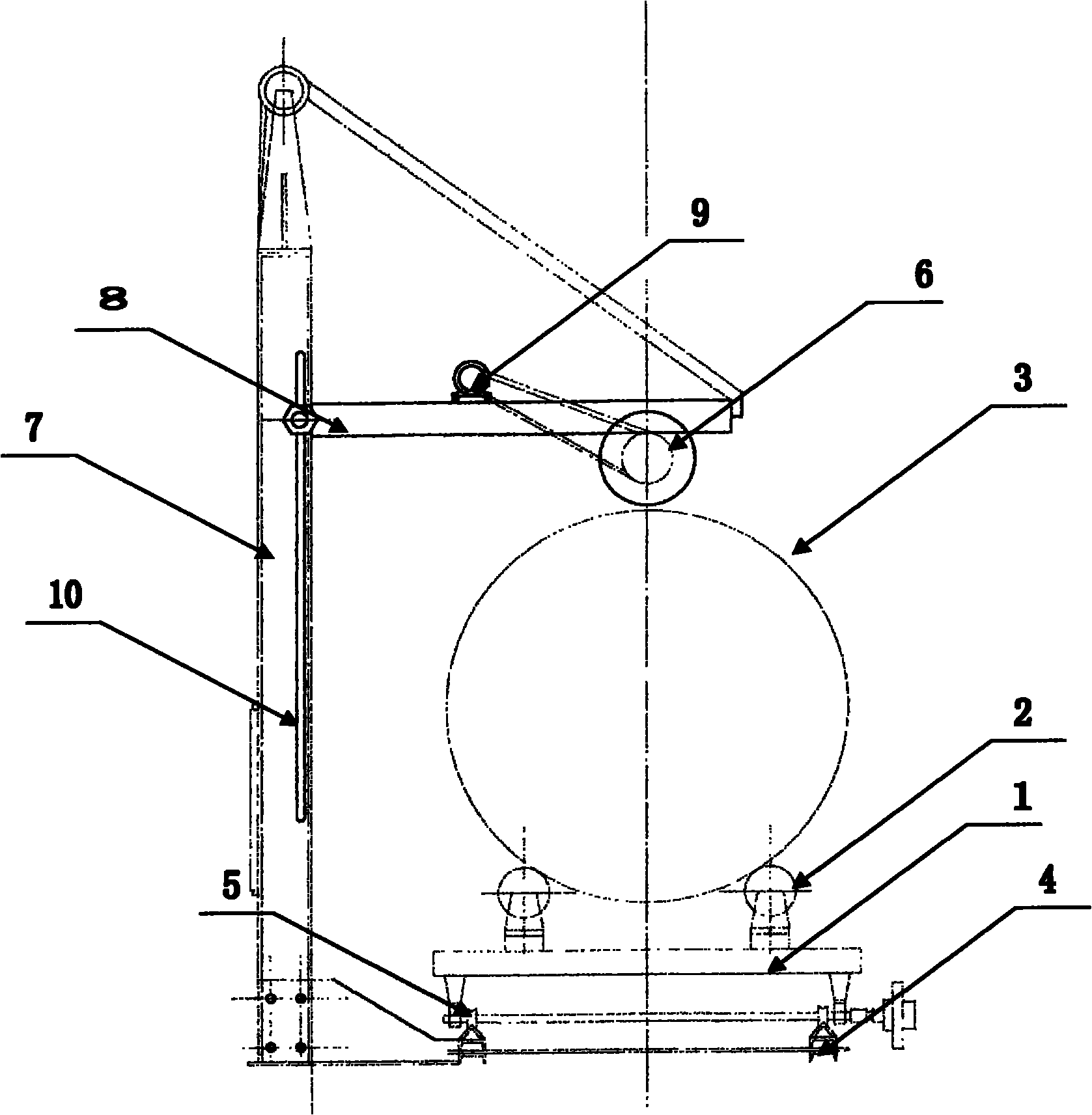

[0006] As shown in accompanying drawing 1 and accompanying drawing 2, a movable workbench (1) is provided, and a row of multiple workbench rollers (2) are respectively arranged on both sides of the movable workbench, and the workpiece (3) to be processed, such as a cylinder or a tank, is placed On the workbench roller (2), when polishing, the workbench roller (2) drives the cylinder or tank of the workpiece (3) to rotate; the movable workbench (1) is provided with rails (4), and the movable workbench (1) ) can move back and forth on the track (4) through the track rollers (5), and a disc throwing bracket (7) is set on the side of the movable workbench (1) and the track (4), and the disc throwing bracket (7) is provided with a disc throwing Boom (8), under throwing dish boom (8) is hung with throwing dish boom counterweight (10), and throwing dish (6) is installed in throwing dish boom (8) front, is driven by motor (9) and carries out polishing operation. In this way, when the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com