Rack and gear-ring protecting cover structure of dumping vehicle

A technology of tipping cars and rack teeth, which is applied in the direction of casting molten material containers, metal processing equipment, casting equipment, etc., can solve the problem of burning arc-shaped ring gears or racks, increase the friction force between racks and racks, and racks The ring gear is easy to wear and equal, so as to achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

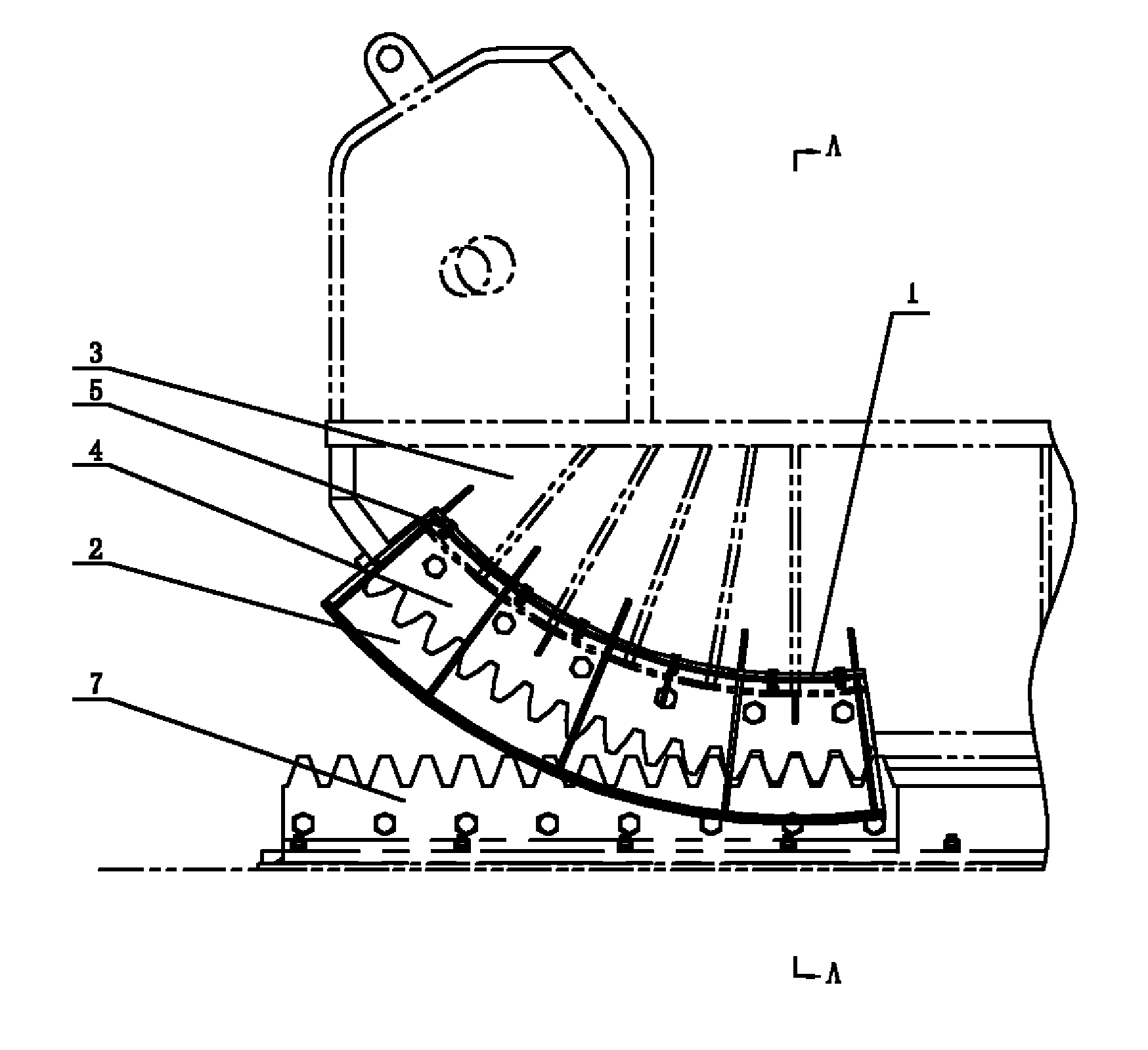

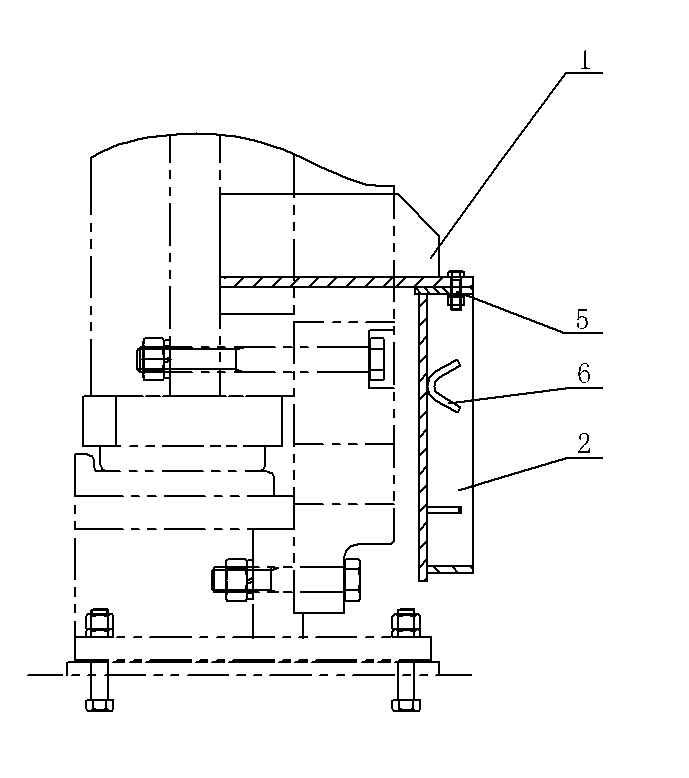

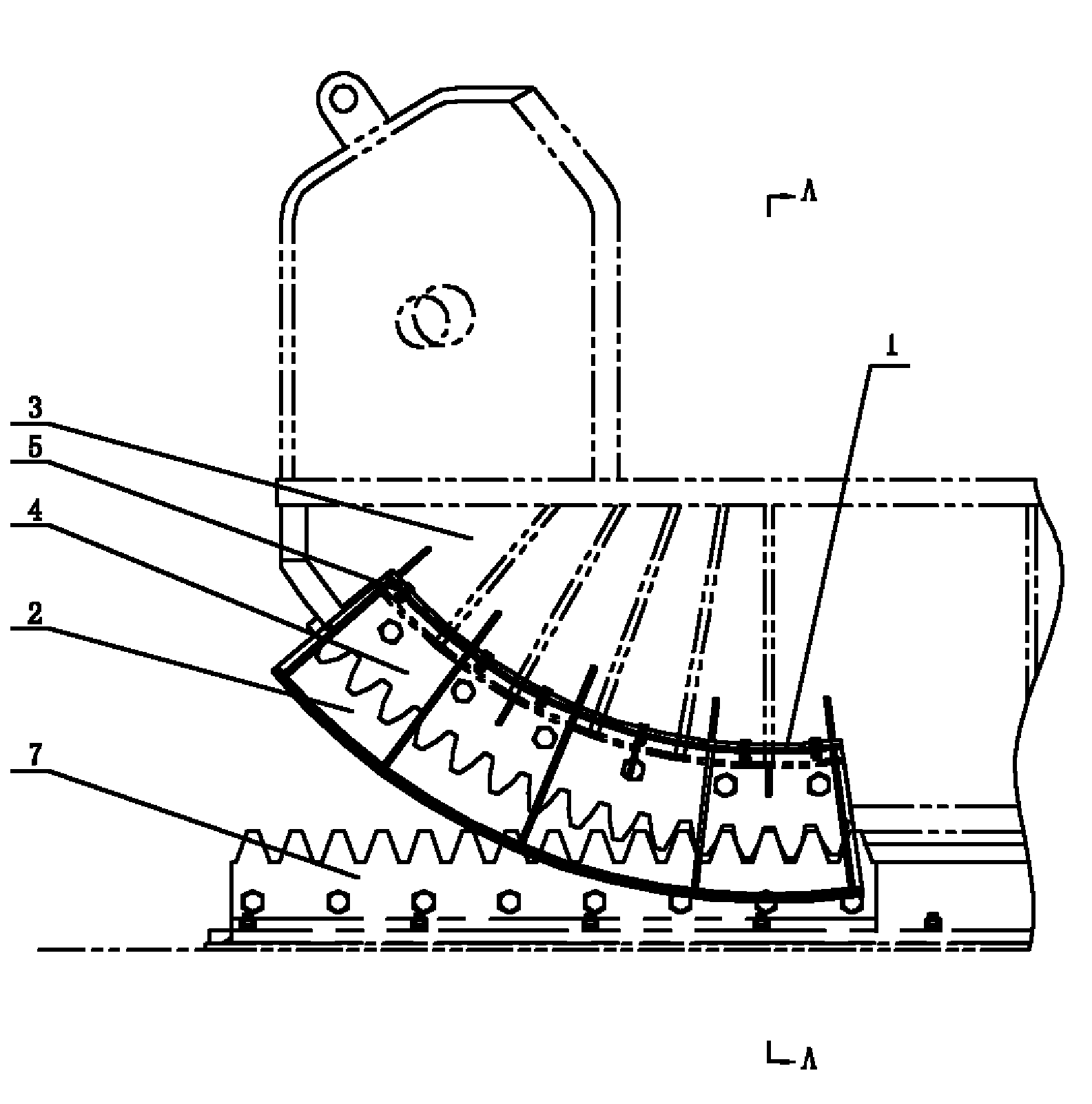

[0009] See Fig. 1 and Fig. 2, the present invention includes a bracket 1 and a guard plate 2, and the guard plate 2 is installed on the outside of the arc-shaped ring gear 4 of the tipping tank seat 3 of the tipping vehicle through the bracket 1 . Bracket 1 is installed on the outer side of tilting tank seat 3 of the tipping vehicle, and guard plate 2 is hung on the lower part of bracket 1 through bolts 5; both bracket 1 and guard plate 2 are arc-shaped, and the arc is the same as arc-shaped ring gear 4; The outside of the board 2 is sprayed with refractory mud; the outer surface of the guard plate 2 is welded with V-shaped nails 6, which play a role in fixing the refractory mud. figure 1 Among them, 7 is the stand rack.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com