Method for cooling sand temperature regulator cooling water through earth cooling

A regulator and cooling water technology, applied in the cleaning/processing machinery of casting mold materials, casting molding equipment, metal processing equipment, etc., can solve the waste of resources, energy and economy, consume a lot of manpower and material resources, and waste water resources and other issues, to achieve significant economic and social benefits, solve waste, and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

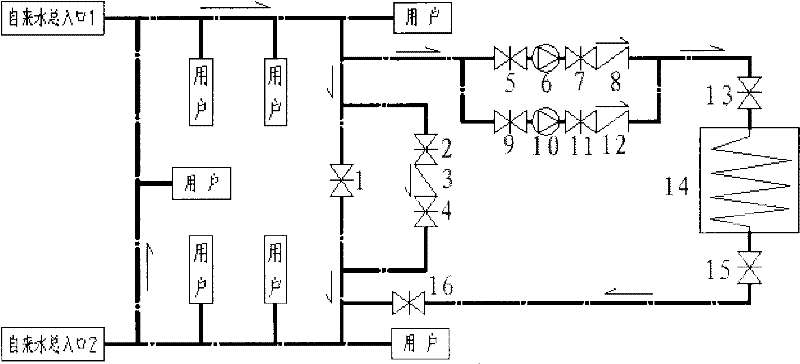

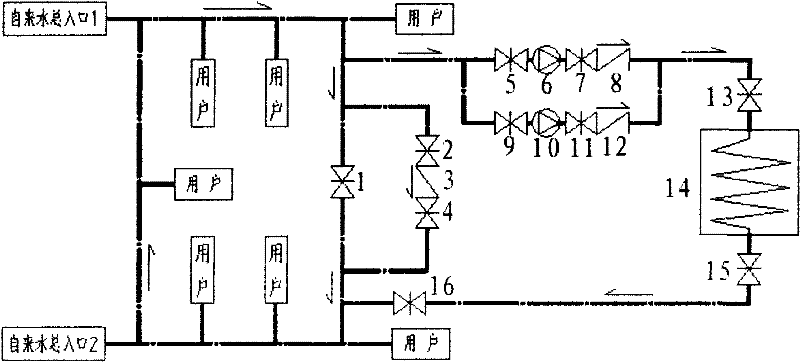

[0010] In the figure: 1, the first gate valve, 2, the second gate valve, 3, the first check valve, 4, the third gate valve, 5, the fourth gate valve, 6, the first circulation pump, 7, the fifth gate valve, 8, The second check valve, 9, the sixth gate valve, 10, the second circulation pump, 11, the seventh gate valve, 12, the third check valve, 13, the eighth gate valve, 14, the sand temperature regulator, 15, the ninth Gate valve, 16, the tenth gate valve.

[0011] The cooling circulation water pipeline of the sand temperature regulator is connected in parallel with the main tap water pipeline, and the heat exchange pipelines distributed underground are connected to make it a closed circulation system; the cooling circulation water of the foundry regenerated sand is cooled by using the underground cold energy.

[0012] The closed circulation system formed by the parallel connection of the sand temperature regulator cooling circulation water pipeline and the tap water main pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com