Hydrodewaxing catalyst as well as preparation method and application thereof

A hydrodewaxing and catalyst technology, applied in catalyst activation/preparation, catalyst carrier, molecular sieve catalyst, etc., can solve the problems of paraffin selectivity reduction, molecular sieve frame collapse, catalyst reduction, etc., to achieve low cracking capacity and reduce side effects. Reaction, effect of high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

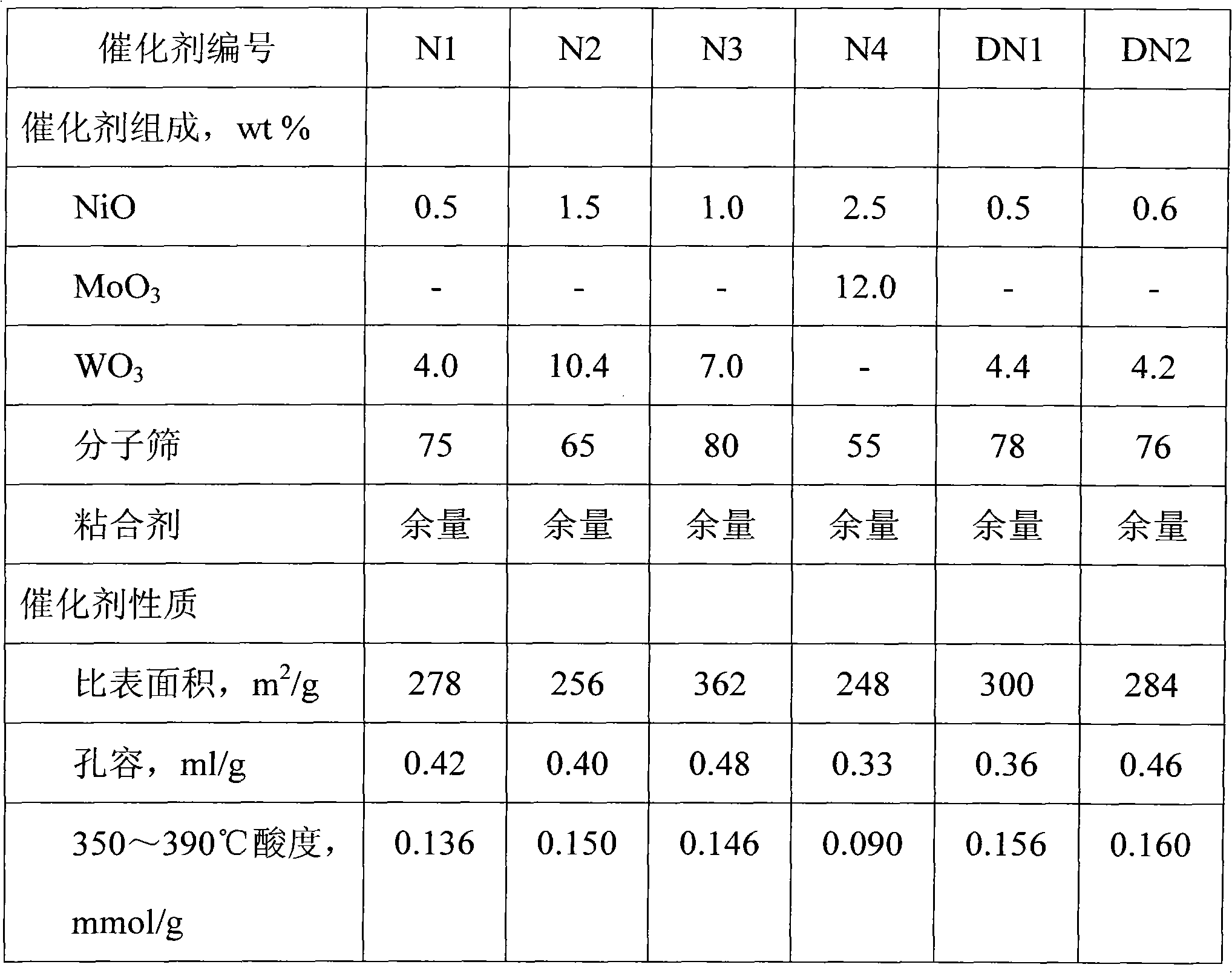

Image

Examples

Embodiment 1

[0028] Will be made of small hole alumina (specific surface 238m 2 g -1 , pore volume 0.48mL·g -1 ) is added to HZSM-5 molecular sieve (97wt% on a dry basis, manufacturer: Tianjin Nankai University Catalyst Factory, SiO 2 / Al 2 o 3 molar ratio 38), mixed evenly, extruded, dried at 130°C for 4 hours, and calcined at 580°C for 4 hours to obtain a carrier.

[0029] The above-mentioned carrier is added to an aqueous solution of magnesium nitrate with a weight content of 5% magnesium oxide and impregnated by equal volume for 5 hours. After filtering, the obtained solid phase is dried at 120° C. for 4 hours to obtain a magnesium-modified carrier.

[0030] Add cyclohexane to dimethyl silicone oil to obtain a silicone oil-organic mixed solution with a silicon oxide weight concentration of 15%, and then add the magnesium-modified carrier to the above-mentioned silicone oil-organic mixed solution to impregnate in equal volume, and the immersion time is 3 hours . After filtration, ...

Embodiment 2

[0033] Will be made of small hole alumina (specific surface 238m 2 g -1 , pore volume 0.48mL·g -1 ) was added to HZSM-5 molecular sieve (same as Example 1), mixed evenly, extruded, dried at 130°C for 4 hours, and calcined at 580°C for 4 hours to obtain a carrier.

[0034] Add the above-mentioned carrier to an aqueous solution with a calcium oxide content of 6% calcium nitrate and impregnate it at a volume ratio of 1:1.5 for 4 hours. After filtering, the obtained solid phase is dried at 100°C for 5 hours to obtain calcium-modified carrier.

[0035] Add solvent gasoline to ethyl silicone oil to obtain a silicone oil-organic mixed solution with a silicon oxide weight concentration of 20%, then add the calcium-modified carrier to the above-mentioned silicone oil-organic mixed solution for immersion in a volume ratio of 1:1.5, and the immersion time for 3 hours. After filtration, it was dried at 110° C. for 4 hours and calcined at 560° C. for 4 hours to obtain calcium and silic...

Embodiment 3

[0038] The preparation of the support and the magnesium-modified support is the same as in Example 1.

[0039] Xylene is added to phenylmethyl silicone oil to obtain a silicone oil-organic mixed solution with a silicon oxide weight concentration of 18%, and then the magnesium-modified carrier is added to the above-mentioned silicone oil-organic mixed solution and impregnated at a volume ratio of 1:2. The time is 3 hours. After filtering, it was dried at 120° C. for 4 hours and calcined at 550° C. for 6 hours to obtain a carrier S3 modified by magnesium and silicon, wherein the weight content of magnesium oxide was 3.0%, and the content of silicon oxide surface coating was 5.0%.

[0040] The obtained carrier S3 was immersed in an aqueous solution containing nickel and tungsten, then dried at 120° C. for 5 hours, and calcined at 600° C. for 3 hours to obtain hydrodewaxing catalyst N3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com