Process for producing rich oxygen by VPSA (vacuum pressure swing adsorption) air separation

An air separation and oxygen enrichment technology, which can be used in oxygen preparation, separation methods, and dispersed particle separation, and can solve problems such as high energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

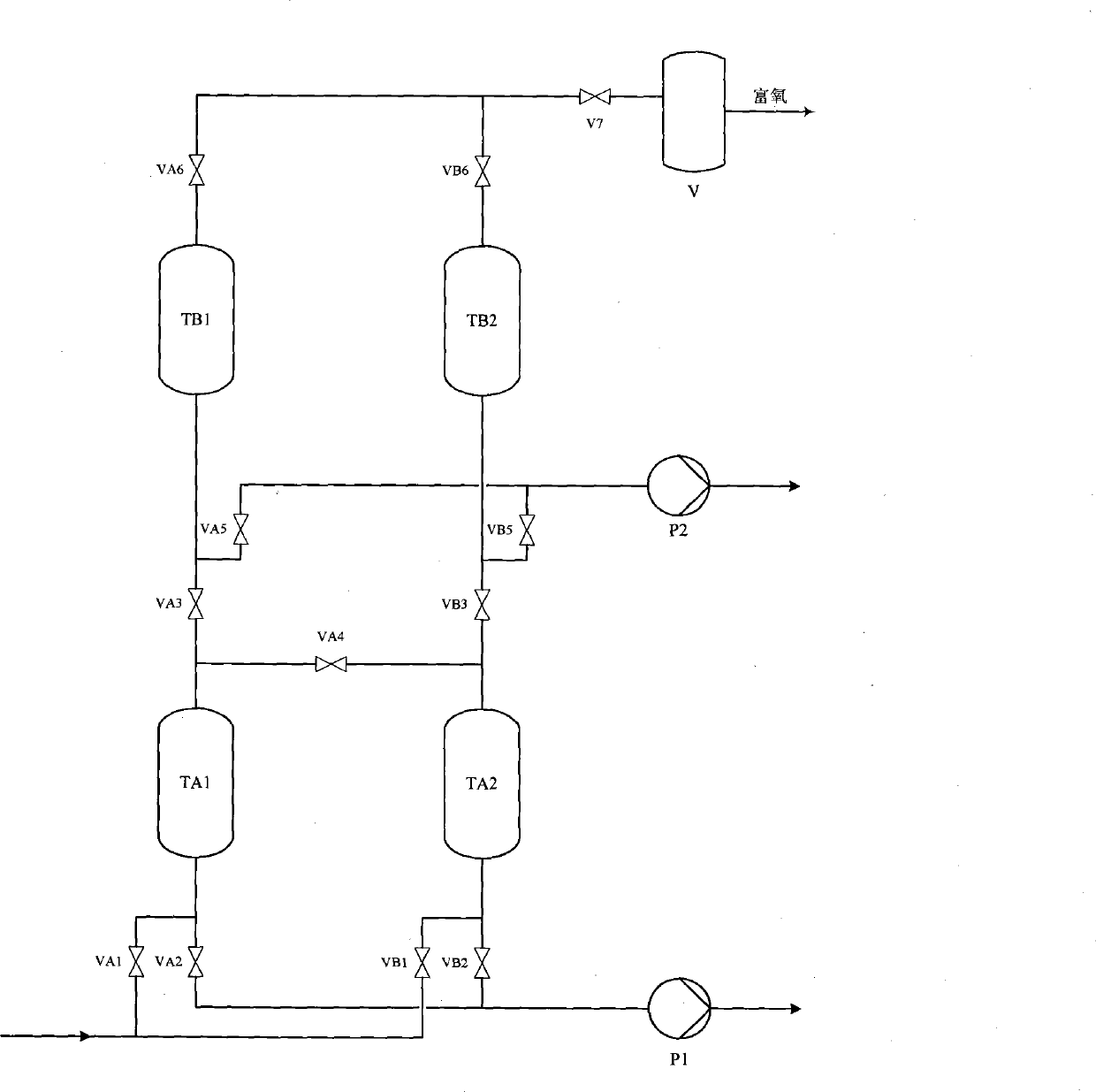

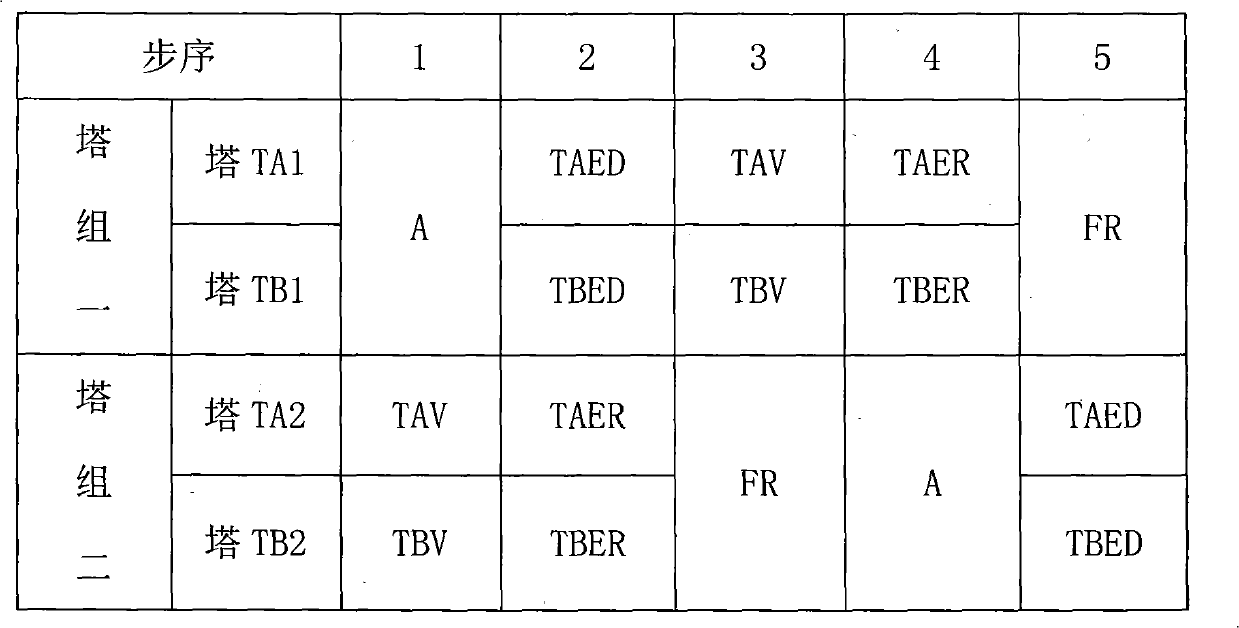

[0020] In a two-tower group VPSA air separation system for oxygen enrichment, taking the tower group composed of towers TA1 and TB1 as an example, the process flow is described as follows:

[0021] (1) Adsorption (A): Open the valves VA1, VA3, VA6, V7, the air enters the tower TA1 from the bottom of the tower, and in the tower TA1, the H in the air 2 O.CO 2 It is successively removed by activated alumina and 13X molecular sieve. Then through valve VA3, it enters TB1 from the bottom. In tower TB1, N2 is adsorbed and removed by oxygen-nitrogen separation molecular sieve, and the formed oxygen-enriched product gas is sent to product gas buffer tank V through valves VA6 and V7. When reaching a specific position in the reserved section of the outlet of the adsorption bed, close the valves VA1, V7, and VA3 to stop the adsorption.

[0022] (2) Parallel pressure equalization and depressurization of the upper and lower towers of the tower group (TAED, TBED): open valves VB6 and VA5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com