Automatic butend sewing and crotch shearing combination machine

A combined machine and sewing head technology, which is applied to sewing machine components, cloth feeding mechanisms, sewing equipment, etc., can solve the problems of low work efficiency, high price, and bulky volume, so as to improve production efficiency, save floor space, and improve automation. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

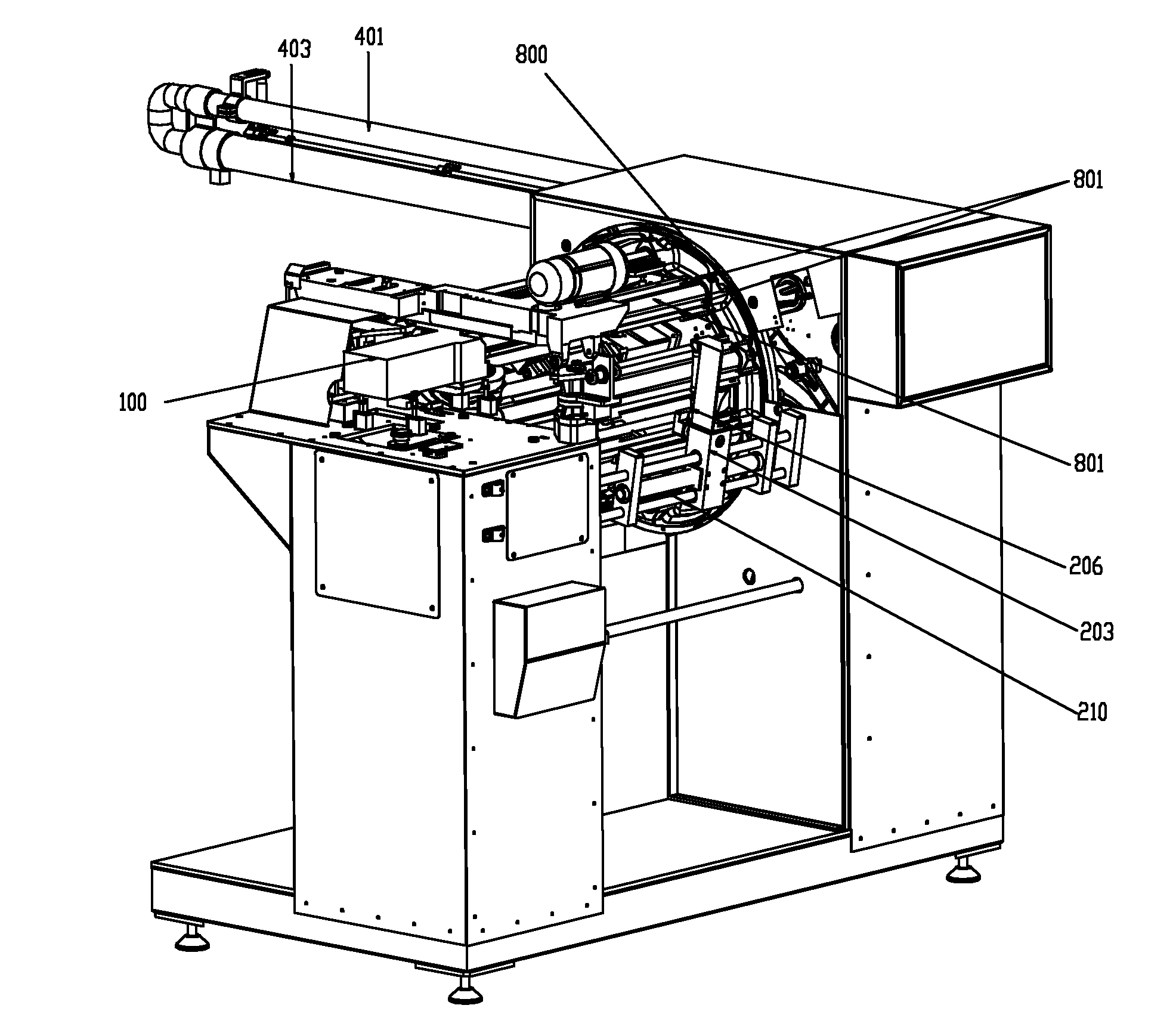

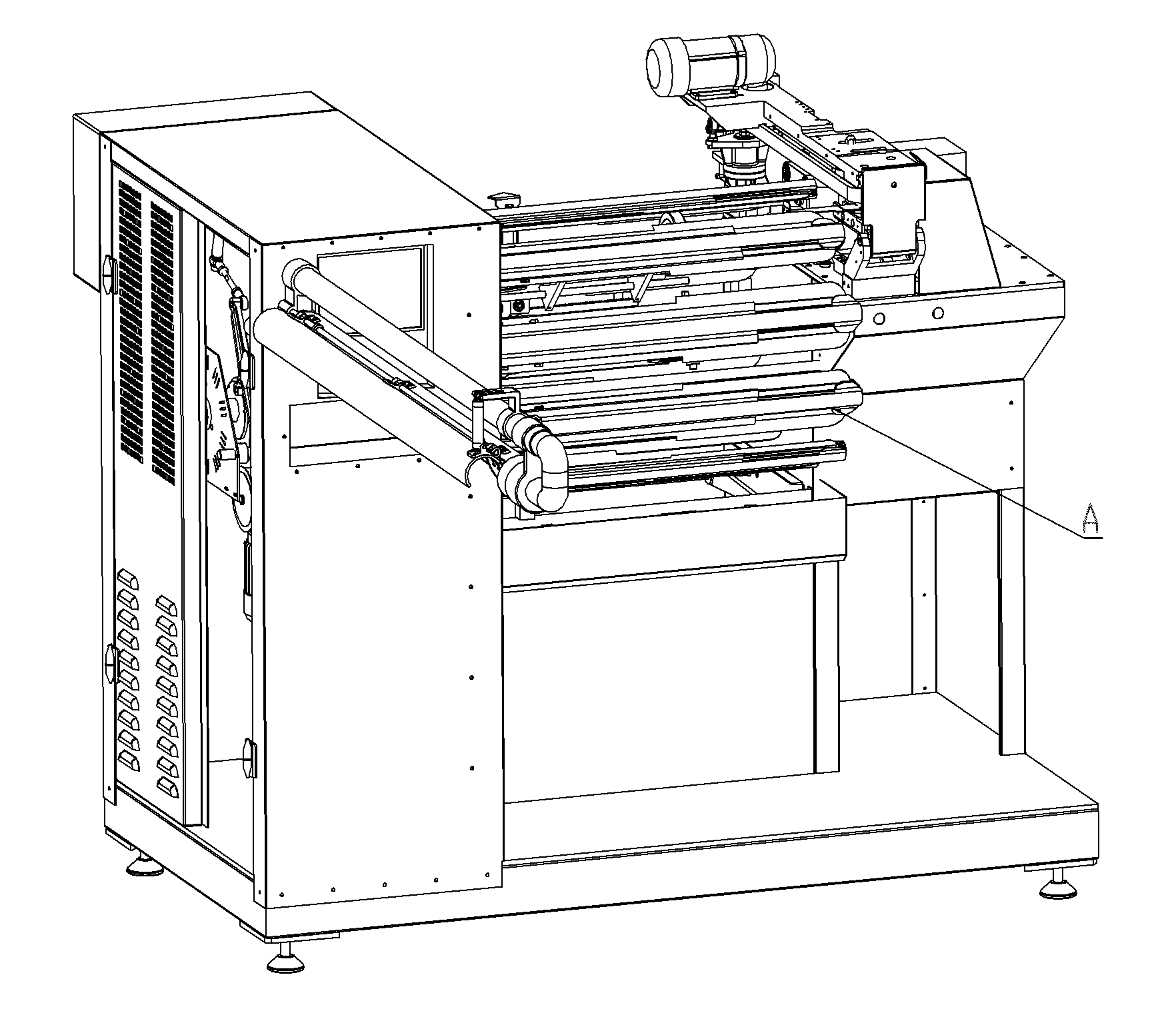

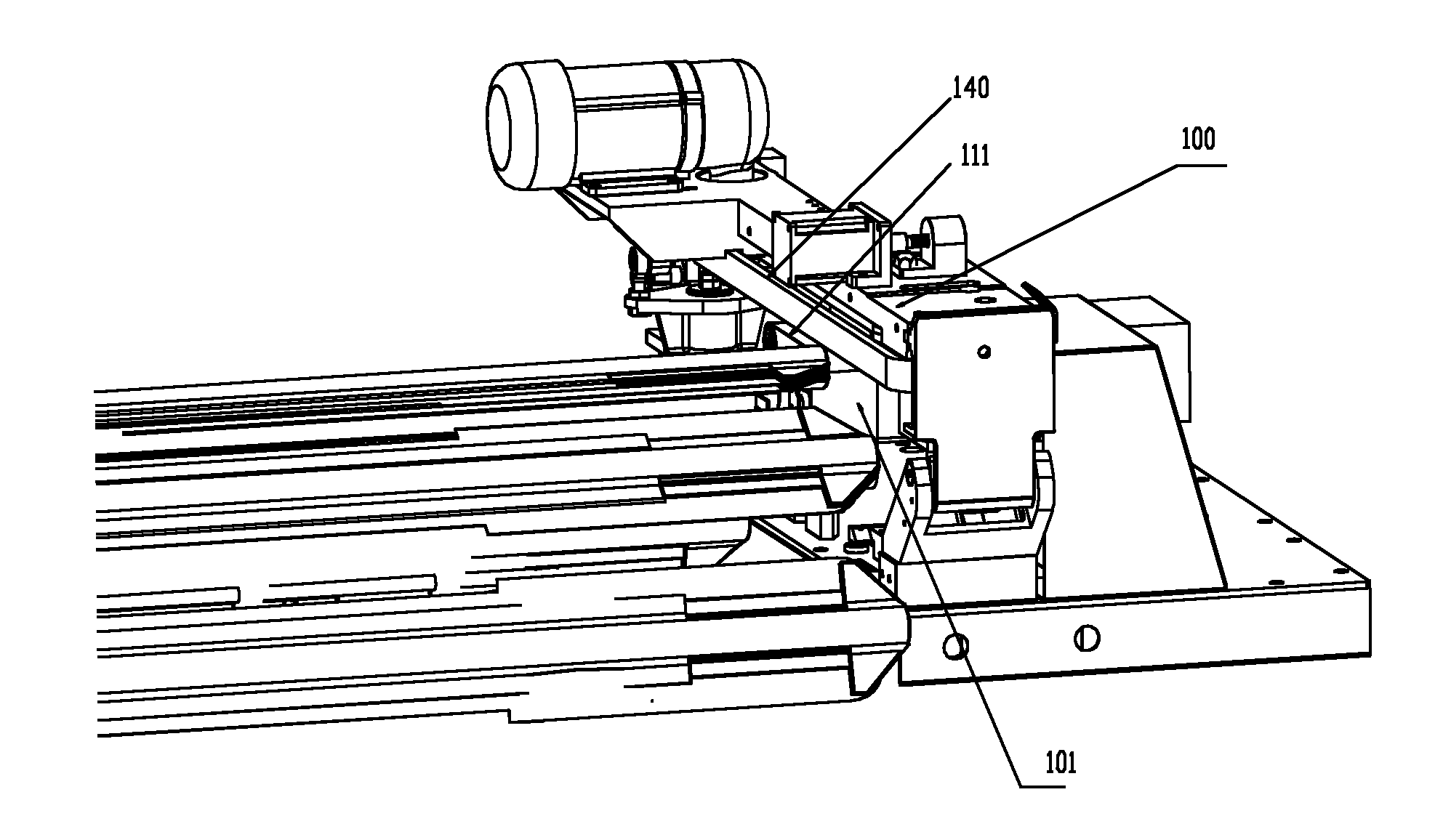

[0034] Refer to attached picture. The present invention includes a mounting frame 800 that rotates around a horizontal axis. The mounting frame 800 may be in the form of a mounting plate. On the same circumference with the center of rotation of the mounting frame 800 as the center, a plurality of vertically vertical For the sock-wearing mechanism of the mounting frame 800, a sock-suction tube 801 is provided in the middle of the sock-wearing mechanism, and there are stretching parts for socks on both sides of the sock-suction tube. The stretching parts can be a plate 802 for wearing socks, such as figure 1As shown, the sock-putting mechanism is installed tangentially on the mounting frame 800, that is, after wearing socks, the socks are lying flat for sewing at the following 12 o'clock direction; between the mounting frame and the sock-putting mechanism At the 12 o'clock direction of the rotating system that rotates around the horizontal axis, there is a sewing head sewing mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com