Full-automatic green soybean shucking machine

A sheller, fully automatic technology, applied in applications, food processing, food science, etc., can solve the problems of low automation, high bean breaking rate, and low shelling efficiency, and achieve improved transmission efficiency and low bean breaking rate , High peeling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

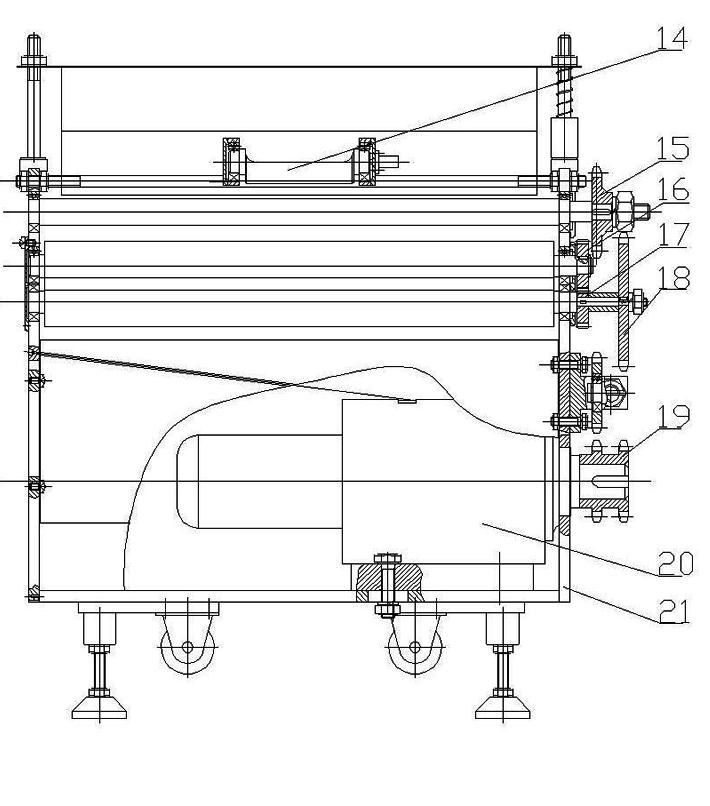

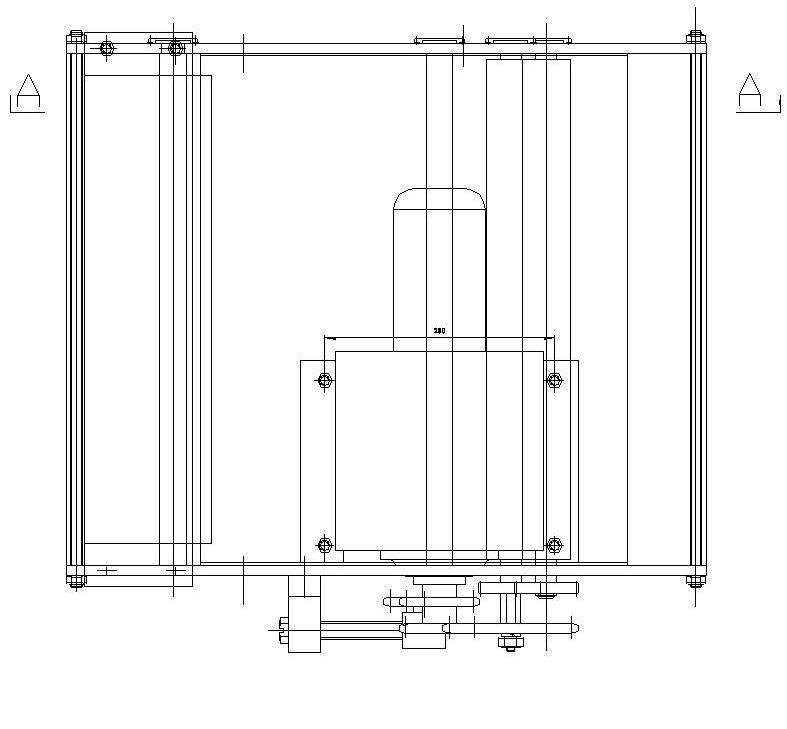

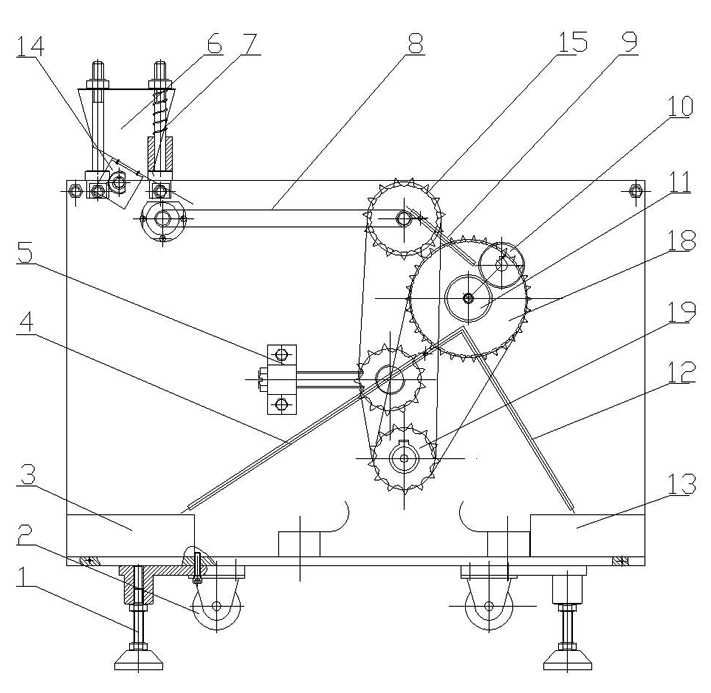

[0025] Such as figure 1 , figure 2 , image 3 As shown, the automatic edamame peeling machine of the present invention is mainly composed of an installation base 1, a body 21, a universal wheel 2, a bean collection box 3, a bean collection guide plate 4, a chain tension adjustment mechanism 5, a storage hopper 6, a partition Vibrating spring 7, conveyor belt 8, blanking guide plate 9, roll 10, roll 11, bean shell collection guide plate 12, bean shell collection box 13, eccentric vibrator 14, sprocket 15, gear 16, gear 17, chain Wheel 18, double sprocket wheel 19, motor 20, body 21 form.

[0026] Wherein, the body 21 is installed on a flat ground by installing the feet 1, and the installation feet 1 and the universal wheels 2 are installed on the bottom of the body 21 for moving and fixing the body 21, and various functional units are installed on the body, Complete the feeding of edamame, the separation of bean grains and bean shells, and the separation of bean grains and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com